No Vent, No Problem – Your Guide to Ventless Hood Systems for Restaurants

Why Ventless Hood Systems Are Revolutionizing Restaurant Kitchens

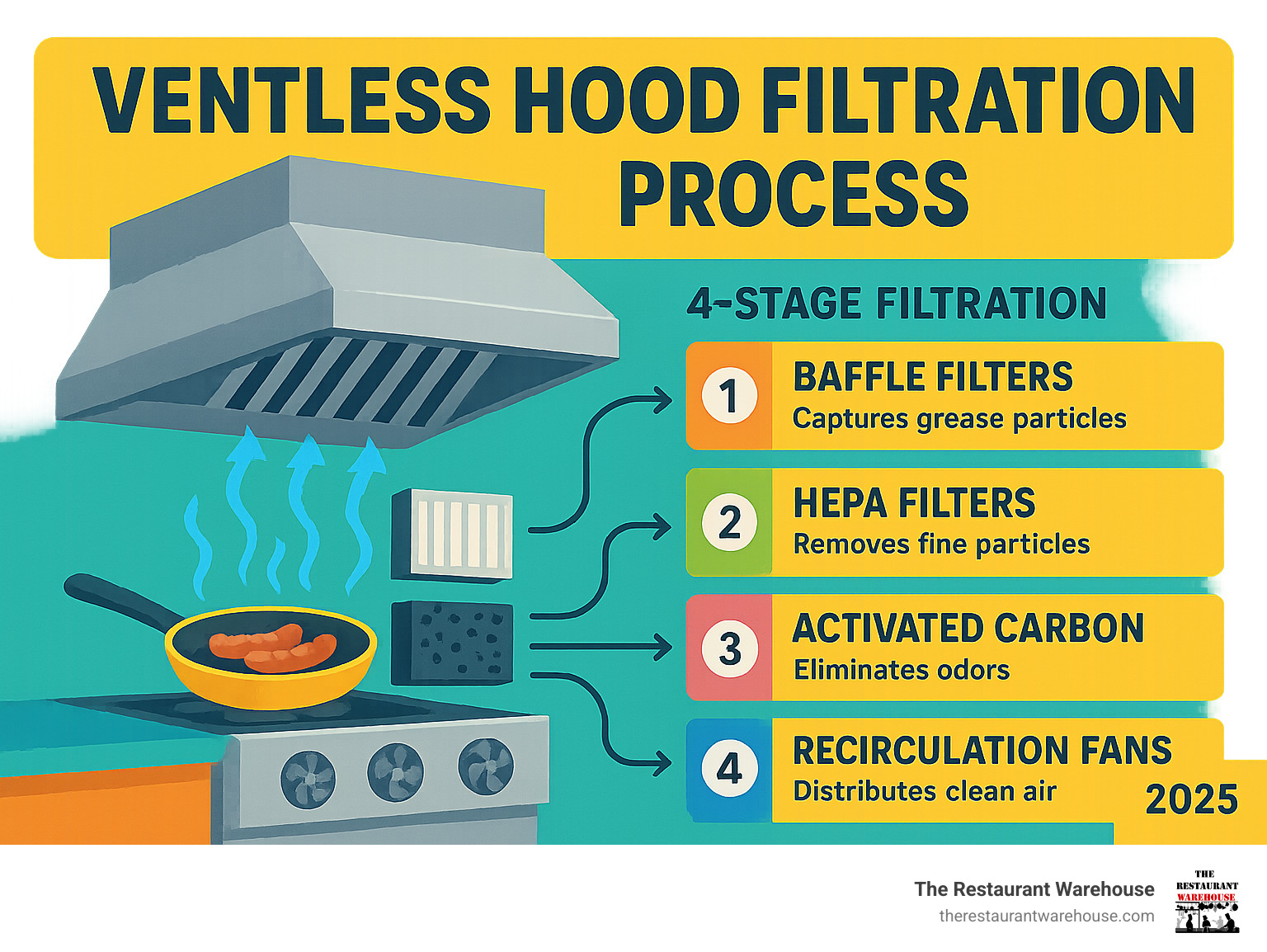

Ventless hood systems for restaurants eliminate the need for expensive ductwork while keeping your kitchen clean and safe through advanced multi-stage filtration. These self-contained units capture grease, smoke, and odors, then recirculate filtered air back into your space - making them perfect for locations where traditional exhaust systems aren't feasible.

Key benefits of ventless hood systems:

- No ductwork required - Install anywhere with adequate ventilation

- Lower upfront costs - Avoid expensive roof penetrations and HVAC modifications

- Portable design - Move equipment as your business grows

- 4-stage filtration - Baffle filters, HEPA filters, and activated carbon remove contaminants

- Built-in fire suppression - Integrated Ansul systems provide safety compliance

- UL710B certified - Meet health department and fire code requirements

This technology opens doors for restaurants in historic buildings, leased spaces, pop-up locations, and anywhere traditional venting is prohibited or cost-prohibitive. Whether you're launching a ghost kitchen or expanding an existing operation, ventless systems offer the flexibility to cook where opportunity calls.

Ventless hood systems for restaurants word guide:

- commercial kitchen stainless steel tables

- heavy duty kitchen equipment

- restaurant equipment wholesale

How Do Ventless Hood Systems Work?

Ventless hood systems for restaurants combine smart airflow, tough filtration, and built-in fire protection to deliver clean, safe air without roof penetrations.

It starts with a powerful capture zone above your cookline. Heavy-duty fans pull smoke, grease, and steam into the system. Instead of exhausting air outside, the ventless hood puts it through thorough filtration.

First, baffle filters made from stainless steel grab grease particles. Next, fine mesh filters catch smaller particles. HEPA filters with super-fine fibers remove tiny contaminants. Finally, activated carbon filters trap odors and volatile organic compounds.

Once clean, recirculation fans send air back into your kitchen. This closed-loop approach keeps air quality high and energy bills low.

Safety is built in with integrated Ansul R-102 wet chemical fire suppression systems that activate automatically, meeting latest fire safety standards without separate installations.

Everything meets strict UL710B and NFPA 96 standards for code compliance.

The Science Behind Ventless Filtration

As cooking fumes rise, the hood's fans create proper capture velocity to pull everything into the system efficiently.

Grease removal uses impingement - grease droplets hit baffles, combine, and drain away safely. Each filtration stage removes progressively smaller particles through the HEPA filter.

Activated carbon filters tackle odors through chemical attraction, trapping odor molecules and airborne contaminants. This means guests only smell your food, not fryer oil.

Ventless systems meet EPA 202 emissions standards, keeping grease emissions well below 0.0029 lb/hr/ft for inspection compliance.

Safety Certifications That Matter

When shopping for ventless hood systems for restaurants, certifications provide peace of mind.

UL710B certification means the hood passed rigorous safety and performance tests for ventless recirculating hoods, providing verified fire protection, electrical safety, and reliable filtration.

ANSI compliance shows the system meets American standards for commercial kitchen ventilation.

NSF certification ensures food safety - every component meets strict sanitation standards. Learn more about NSF certification.

NFPA 96 compliance ensures your hood meets National Fire Protection Association standards for fire suppression and safe operation.

These certifications mean your system handles health department inspections, fire marshal visits, and local code requirements.

Benefits & Cost Comparison of Ventless vs. Traditional Hoods

The financial advantages of ventless hood systems for restaurants extend far beyond initial purchase price. Total cost of ownership analysis shows ventless systems consistently deliver superior ROI.

Capital cost savings represent the most immediate benefit. Traditional ducted systems require expensive roof penetrations, extensive ductwork, and make-up air systems adding $15,000-$50,000 to project budgets. Ventless systems eliminate these costs entirely.

HVAC load reduction provides ongoing savings. Traditional exhaust hoods remove conditioned air, forcing heating and cooling systems to work harder. Ventless systems recirculate filtered air, reducing energy consumption by up to 30%.

Installation speed translates to faster revenue generation. While ducted systems require weeks of construction, ventless units can be operational within days.

| Cost Factor | Traditional Ducted | Ventless System |

|---|---|---|

| Equipment Cost | $8,000-$15,000 | $10,000-$17,000 |

| Ductwork Installation | $10,000-$30,000 | $0 |

| Roof Work | $5,000-$15,000 | $0 |

| Make-up Air System | $8,000-$20,000 | $0 |

| Installation Time | 2-6 weeks | 1-3 days |

| Total Initial Investment | $31,000-$80,000 | $10,000-$17,000 |

Why Restaurants Choose Ventless Hood Systems for Restaurants

Lease restrictions frequently prohibit roof penetrations. Ventless systems respect these limitations while providing full cooking capabilities.

Historic buildings present unique challenges. Preservation requirements often prohibit exterior modifications, making ventless the only viable option.

Pop-up restaurants and food trucks benefit from portable design. Equipment relocates as business opportunities change.

Ghost kitchens frequently operate in non-traditional spaces where ductwork is impractical. Ventless systems enable these business models by removing location constraints.

Hidden Savings Over Time with Ventless Hood Systems for Restaurants

Duct cleaning elimination saves $500-$1,500 annually. Traditional systems require monthly professional cleaning for fire safety compliance.

Reduced energy loss from conditioned air exhaust saves 20-40% on heating and cooling costs.

Filter replacement budgeting is predictable. Typical filter costs range from $200-$500 quarterly, depending on cooking volume.

Insurance benefits may apply due to integrated fire suppression systems.

Choosing the Best Ventless Hood Systems for Restaurants

Choosing the perfect ventless hood systems for restaurants means matching your kitchen's needs, cooking style, and space to the right solution.

Equipment compatibility is crucial. Ventless systems work with electric appliances only - electric fryers, griddles, convection ovens, and steamers. Gas equipment requires traditional vented hoods.

System types include canopy-style ventless hoods mounted above equipment, universal ventless hoods for maximum flexibility, and all-in-one units with integrated cooking equipment.

Cooking volume determines filtration capacity needs. High-traffic kitchens need bigger or multiple filtration modules for rush hours.

Electrical requirements typically need 208-240V power supply. Check your kitchen's electrical panel before purchasing.

Space planning requires measuring ceiling height (8+ feet minimum), filter access room, and delivery clearances. Most units need 1,200-1,800 CFM following the "200 CFM per linear foot" rule.

Sizing Your Hood Correctly

Getting the right size is critical. Too small means smoky air and code violations. Too big wastes energy and money.

Match hood footprint to equipment with at least 6-inch overhang on all sides for proper capture.

Use the 200 CFM per linear foot rule - a 4-foot hood needs minimum 800 CFM, while 6-foot hoods need 1,200+ CFM.

For fryers, check maximum oil and kettle sizes - most ventless hoods limit around 85 pounds of oil or 470 square inches of fryer area.

Clearance requirements need 18+ inches between cooking surface and hood, plus maintenance access room.

Key Features Checklist

Look for interlock systems that prevent equipment operation if filters are missing or fire suppression is active.

LED alerts provide maintenance reminders: green for go, yellow for maintenance soon, red for urgent attention.

Swivel casters help with cleaning and layout changes. Stainless steel construction (18-gauge) ensures durability.

Warranty terms should include at least one year on parts and labor. Integrated fire suppression with Ansul R-102 systems provides industry-standard protection.

For more kitchen design help, visit our resource center for restaurant setup tips.

Installation & Maintenance Made Simple

Getting your ventless hood systems for restaurants running is straightforward compared to traditional ducted systems. Most owners are amazed how quickly they go from delivery to serving customers.

Before arrival, verify ceiling height (8-10 feet minimum), electrical service availability, and maintenance access space. Locate fresh air sources - your system needs good airflow.

Modern ventless hood systems for restaurants offer plug-and-play design. Position the unit, connect electrical service, and have fire suppression charged by a certified technician. No waiting for ductwork, roof modifications, or construction crews.

Ansul system charging requires professional expertise but takes just hours. This activates fire protection and ensures regulatory compliance.

Fresh air makeup planning ensures optimal performance. Your kitchen needs sufficient fresh air sources, sometimes requiring ventilation fans or HVAC adjustments.

DIY vs. Professional Install

Knowing which tasks you can handle versus which require professionals saves time and ensures safety.

Local permits vary by location. Check commercial cooking equipment requirements - some jurisdictions treat ventless systems more favorably than traditional hoods.

Electrical connections need licensed electricians. Commercial kitchen electrical work requires proper grounding and safe operation.

Schedule fire marshal inspection after installation but before opening. Having documentation organized makes this smoother.

DIY-friendly tasks include positioning, filter installation, and basic setup. Budget for professional fire suppression charging, electrical connections, and inspections.

Routine Care to Maximize Lifespan

Maintaining ventless hood systems for restaurants is refreshingly simple with predictable requirements.

Monthly baffle filter washing maintains airflow. Most are dishwasher-safe, making this routine cleaning.

Quarterly HEPA filter replacement maintains fine particle filtration. Regular replacement ensures consistent air quality.

Carbon filter timing depends on cooking volume. High-odor cooking needs monthly changes; lighter operations can stretch to quarterly.

Annual fire system inspection keeps compliance current. Certified technicians check operation and verify suppression levels.

Modern systems use color-coded alert monitoring - green means go, yellow signals maintenance due, red means immediate attention needed.

Keep documentation of filter changes, inspections, and service work for health department visits and cost tracking.

Frequently Asked Questions about Ventless Hood Systems

Do ventless hoods meet health and fire codes everywhere?

Here’s the short answer: ventless hood systems for restaurants with proper UL710B certification meet health and fire codes in most places—but there’s a little fine print to keep in mind.

Most health departments view UL710B-listed ventless hoods as equivalent to traditional Type-1 hoods when installed and maintained correctly. That’s good news if you’re hoping to skip the headaches (and costs) of ductwork. Still, every city and county can have its own rules. Some places may have extra steps or unique paperwork, so it’s always smart to double-check with your local health department before ordering.

On the fire safety side, ventless systems with built-in fire suppression are typically accepted by fire marshals. However, inspections are almost always part of the process, and you’ll want to have your certifications, install records, and maintenance logs ready to show. Fire marshals love paperwork—don’t give them a reason to frown!

The best move is to get in touch with your local authorities early in your planning. Share your hood system’s certifications and specs, and ask if there are any extra hoops to jump through. This simple step can save you time, money, and a few gray hairs down the line.

How often do the filters need to be replaced?

The answer depends on how busy your kitchen is and what you’re cooking. For ventless hood systems for restaurants, filter care is crucial to keep your air clean (and your inspector happy).

- Baffle filters are made from stainless steel and built to last. With regular monthly cleaning—usually a quick trip through the dishwasher—they can keep working for 2-5 years or more.

- HEPA filters are the workhorses for fine particles. For most kitchens, a swap every 3-6 months does the trick. Cooking up a storm all day? You might need to replace them as often as once a month.

- Activated carbon filters handle the odors. If you’re frying or cooking aromatic foods often, you’ll want to replace these every 1-2 months. For lighter cooking, quarterly changes might be enough.

- Pre-filters (if your system includes them) usually need monthly attention in high-traffic kitchens. They’re inexpensive and help protect your main filters, so don’t put off changing them when they get dirty.

Most modern ventless hoods have indicator lights that let you know when it’s time for a filter check or change—no need to guess or set a calendar reminder.

Can gas equipment be used under a ventless hood?

A common question, and here’s the simple answer: No, ventless hood systems for restaurants are designed only for electric cooking equipment. Gas appliances are a no-go.

That’s because ventless hoods are engineered to filter and recirculate air from electric fryers, griddles, ovens, and similar gear. Gas appliances produce different byproducts—like carbon monoxide—that these filters can’t safely handle. Trying to use gas under a ventless hood isn’t just against the rules, it’s a major safety hazard.

If your menu relies on gas cooking, you’ll need to stick with traditional ducted ventilation. But don’t worry—electric cooking equipment has come a long way, and you’ll find electric fryers, ranges, and convection ovens that can handle almost any recipe without missing a beat.

For more about choosing the right setup, visit our More info about commercial kitchen setup page. And remember, if you have questions about the right ventless hood systems for restaurants, our team at The Restaurant Warehouse is always here to help you cook up something great—safely and affordably.

Conclusion

Ventless hood systems for restaurants are changing the game for commercial kitchens. Whether opening in historic buildings, dealing with lease restrictions, or wanting quick setup, these systems make it possible without compromising safety or air quality.

By eliminating ductwork, you skip high installation costs and construction delays. Instead, you get streamlined, energy-efficient ventilation that keeps food sizzling and air fresh while trimming utility costs. The investment pays for itself quickly through lower upfront costs and ongoing savings.

Ventless hood systems for restaurants provide flexibility. Move your kitchen, change your menu, or expand into new spaces without major overhauls. Whether running ghost kitchens, pop-ups, or revitalizing old buildings, ventless technology lets you cook where and how you want.

At The Restaurant Warehouse, we focus on wholesale pricing, cutting out high commissions and markups. Our goal is helping you get professional-grade ventless hood systems at sensible prices - so you can invest in your food and team, not just infrastructure.

With advanced multi-stage filtration, built-in fire suppression, and top safety certifications, these systems are smart, future-ready choices for safe, efficient, profitable kitchens. The restaurant world is evolving, and ventless hoods lead the way to more flexible, creative, cost-effective operations.

Ready to see what's possible? Our team helps you choose, size, and set up the right system. For step-by-step help and setup ideas, check our commercial kitchen setup guide.

The future of kitchen ventilation is brighter and cleaner. With ventless hoods, there are no vents, no limits, and no excuses. Just fresh air, flexible locations, and freedom to build your culinary dreams.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment