Industrial Ovens for Baking: Your Recipe for Bakery Success

Why Industrial Ovens for Baking Are Your Gateway to High-Volume Success

Industrial ovens for baking are heavy-duty cooking systems designed for continuous, high-volume production in commercial bakeries, restaurants, and food manufacturing facilities. Unlike standard commercial ovens, these powerhouses handle massive throughput while maintaining consistent temperature control and product quality.

Key features that define industrial baking ovens:

- Temperature range: 180°F to 1,000°F (typical baking: 350°F-500°F)

- Capacity: From 8-pan rack systems to massive tunnel ovens

- Heat sources: Gas, electric, infrared, or dual-fuel systems

- Operation: Built for 24/7 continuous use

- Efficiency: Up to 50% more energy-efficient than standard ovens

The difference between success and struggle in high-volume baking often comes down to your oven choice. As one industry expert noted, "some kitchens for bakeries and restaurants build their entire layout around the oven choice" - because the wrong equipment can disrupt your entire operation.

Whether you're scaling up a bakery, launching a pizza operation, or adding baked goods to your restaurant menu, understanding industrial oven types and their capabilities is crucial for making smart equipment investments.

Modern industrial ovens offer game-changing innovations like dual-fuel flexibility, programmable controls, and energy recovery systems. These features help future-proof your business against rising energy costs while delivering the consistency and speed your customers expect.

Industrial ovens for baking terms at a glance: - commercial deck oven - commercial ovens - electric conventional oven

Understanding Industrial Ovens for Baking

Industrial ovens for baking are built for a completely different league than standard kitchen equipment. These machines can bake hundreds of loaves, thousands of cookies, or dozens of sheet cakes simultaneously while maintaining precise temperatures and consistent results.

Industrial ovens operate on temperature ranges from 180°F to 1,000°F, with most baking applications falling between 350°F and 500°F. But temperature range is just the beginning of what makes these machines special.

What Makes an Oven "Industrial"?

Industrial ovens are the marathon runners of the baking world. While regular ovens might handle a busy dinner rush, industrial units are built for continuous operation - sometimes running 24 hours a day, seven days a week.

The heavy-duty construction starts with reinforced steel frames that handle constant thermal expansion and contraction. The insulation is engineered to maintain consistent temperatures while minimizing energy loss.

Larger baking chambers accommodate multiple full-size sheet pans simultaneously, or conveyor systems that move products through heating zones automatically. Some tunnel ovens stretch over 100 feet long, processing thousands of items per hour.

The temperature uniformity in industrial units maintains temperatures within ±5°F across the entire baking chamber. Advanced airflow systems with powerful fans circulate heated air evenly, eliminating hot spots and cold zones.

Key Applications for Industrial Ovens for Baking

Bread production relies on deck ovens that provide radiant heat similar to traditional stone hearths. Steam injection during initial baking creates perfect crispy crusts while keeping interiors soft and airy.

Pizza operations demand high-temperature capabilities, often reaching 450°F to 500°F for authentic crust development. Deck ovens excel here, though conveyor systems work brilliantly for high-volume operations.

Pastries and cakes require the gentle, even heat that convection ovens provide. Precise temperature control prevents delicate items from burning while ensuring proper rise and golden browning.

Cookie and cracker production often uses tunnel ovens with controlled conveyor speeds for continuous production of large batches while maintaining uniform texture and color.

Gluten-free and specialty products present unique challenges, often requiring dedicated production lines to prevent cross-contamination. Industrial ovens with easy-access cleaning features make it possible to switch between different product types safely.

Top Types of Industrial Baking Ovens & Their Results

Choosing the right oven type dramatically impacts your baking results, production efficiency, and operating costs. Each design offers distinct advantages for specific applications.

Convection, Deck, Rack, Tunnel & Combination Ovens

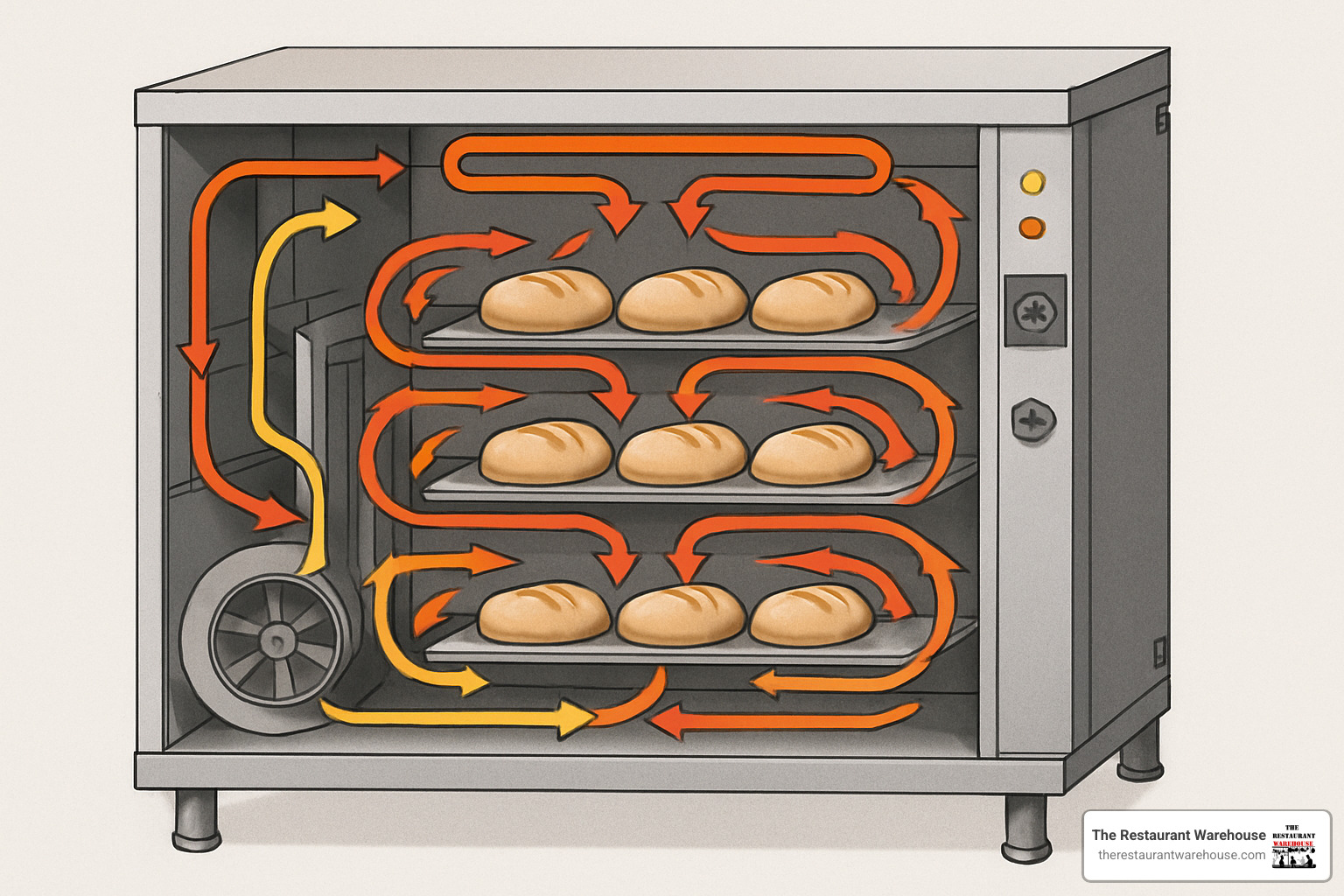

Convection ovens use powerful fans to circulate heated air throughout the baking chamber. This forced airflow creates even temperatures and can reduce baking times by up to 25%. They excel at items requiring consistent browning like cookies, muffins, and sheet cakes.

Deck ovens feature stone or ceramic surfaces that provide intense radiant heat from below. This design mimics traditional brick ovens and creates superior crust development for artisan breads and pizzas. Multiple deck levels allow simultaneous baking at varying temperatures.

Rack ovens accommodate full-size rolling racks loaded with sheet pans. These space-efficient units can handle 8-20 pans simultaneously, making them ideal for high-volume operations producing multiple products.

Tunnel ovens use conveyor belts to move products through controlled temperature zones. This continuous process works perfectly for consistent items like crackers, cookies, or sandwich buns where uniformity is critical.

Combination (combi) ovens offer three cooking modes: steam, hot air, or both combined. The combi mode can cook up to 50% faster than standard convection while retaining moisture.

Electric vs Gas Heating Systems – Pros & Cons

Gas advantages: - Lower operating costs in most regions - Continues operating during power outages - Provides moist heat preferred for bread production - Faster temperature recovery when loading cold products

Gas disadvantages: - Requires gas line installation or propane tank systems - More complex ventilation requirements - Potential for uneven heating without proper burner design

Electric advantages: - Easier installation with standard electrical connections - More precise temperature control and uniformity - Cleaner operation with no combustion byproducts - Infrared electric systems can be up to 50% more energy efficient

Electric disadvantages: - Higher operating costs in many areas - Vulnerable to power outages - May require electrical service upgrades for high-wattage units

At The Restaurant Warehouse, we help customers analyze their local utility rates and operational needs to determine the most cost-effective heating system.

Fuel Choices & Energy Efficiency: Cutting Costs, Carbon & Downtime

Smart fuel choices and efficient heating systems can slash operating costs while keeping your industrial ovens for baking running smoothly during peak production hours.

Infrared heating heats your products directly instead of warming the entire oven chamber. This direct heating approach can cut energy use by up to 50% compared to traditional gas systems, with no warm-up time required.

Modulating burners adjust flame intensity based on actual needs rather than blasting full heat then shutting off completely. This maintains steady heat while using less fuel during lighter production periods.

Heat recovery systems capture hot air that would normally escape through exhaust and put it to work elsewhere. You're essentially recycling 15-30% of the energy that would otherwise disappear up the exhaust stack.

Scientific research on oven efficiency provides detailed analysis of how different heating methods stack up in real-world conditions.

Decarbonization targets are pushing many operations toward cleaner energy sources. Modern efficient ovens help you meet environmental goals while saving money.

Future-Proof Solutions with Hybrid & Dual-Fuel Designs

Energy markets change rapidly, making fuel flexibility crucial for long-term success.

Dual-fuel systems let you switch between gas and electricity based on current rates or availability. Some advanced units even monitor utility pricing automatically and choose the cheaper option.

Retrofit kits protect your existing equipment investment while adding modern capabilities. Instead of replacing a perfectly good oven, you can upgrade it for dual-fuel operation.

Programmable controls optimize fuel usage by learning your production patterns. These systems automatically reduce temperatures during slow periods and pre-heat before busy times begin.

Renewable electricity integration becomes easier when your ovens can switch fuel sources. As solar and wind power become more cost-effective, electric heating options position your operation to take advantage of cleaner energy sources.

Hydrogen-ready burners represent the cutting edge of future-proofing. While hydrogen infrastructure is still developing, some manufacturers are designing burner systems that can adapt to this clean fuel source.

At The Restaurant Warehouse, we help customers evaluate their local energy markets and operational needs to choose systems that make sense both today and tomorrow.

Buying Checklist: Selecting the Perfect Oven for Your Bakery

Choosing the right industrial ovens for baking requires understanding your unique needs rather than just comparing features. The best decisions come from honest assessment of your requirements.

Start by assessing your production capacity needs. Calculate your busiest hour and multiply by 1.3 to account for growth. This prevents outgrowing your equipment too quickly.

Space planning deserves equal attention. Measure available floor space, ceiling height, and door widths for delivery. Electric units need adequate power supply, while gas models require proper line sizing and ventilation.

Energy costs vary dramatically by location and can make or break your operating budget. Get actual utility bills from similar businesses in your area. Factor in both energy rates and maintenance requirements when calculating true operating costs.

Product quality should drive your oven type selection. Artisan breads benefit from deck ovens' radiant heat, while pastry operations need convection systems for even browning. Steam injection matters for crusty breads, while precise temperature control becomes critical for delicate items.

The control interface affects daily operations. User-friendly controls reduce training time and prevent costly mistakes. Advanced systems offer programmable recipes that ensure consistency.

Warranty coverage and service network availability protect your investment long-term. The best oven becomes useless if you can't get parts or qualified technicians when problems arise.

For comprehensive equipment selection guidance, our Commercial Bakery Equipment Guide covers everything from mixers to packaging systems.

10 Must-Ask Questions Before You Buy

What's your target hourly production volume? Be realistic about peak demand, not average sales.

Which products will you bake most frequently? Different items favor specific oven types.

What are your local gas and electric rates? Operating costs vary dramatically by region.

Do you have adequate ventilation capacity? Industrial ovens for baking generate substantial heat and moisture.

How important is cleaning accessibility? Daily maintenance keeps ovens running efficiently.

What's your service support network? Local technician availability affects downtime costs.

Do you need financing options? Equipment loans preserve working capital for inventory and marketing.

Will you expand your product line? Versatile ovens accommodate menu changes better than specialized units.

What's your backup plan for equipment failure? Critical production equipment needs contingency planning.

How will you measure return on investment? Establish clear metrics for productivity gains, energy savings, and quality improvements.

At The Restaurant Warehouse, we help you work through these questions with honest advice focused on finding the right solution for your business.

Cleaning, Maintenance & Troubleshooting

Keeping your industrial ovens for baking in top condition protects your investment and keeps customers happy. A well-maintained oven can last decades, while neglected equipment might fail during your busiest rush.

Daily brush-out of crumbs and debris prevents buildup that can cause hot spots or fires. Wipe down interior surfaces with non-abrasive cloths while the oven is warm but not hot.

Check door gaskets regularly - when they're damaged, you're watching money escape through the cracks. A quick visual check takes seconds but can save hundreds in energy costs.

Monthly deep-clean sessions involve applying appropriate cleaners to interior surfaces and scraping away built-up grease and carbon deposits that daily cleaning can't handle.

Temperature calibration during deep cleans catches problems before they ruin entire batches. Nothing's worse than finding your "350°F" oven is actually running at 380°F after burning a day's worth of artisan bread.

NSF compliance keeps health inspectors happy and your reputation intact. Modern industrial ovens feature smooth, crevice-free surfaces designed to meet these requirements. Document your cleaning procedures - health departments love paperwork.

For detailed cleaning procedures, our Convection Ovens Guide walks you through step-by-step maintenance for different oven types.

Common Challenges & Quick Fixes

Uneven browning often indicates obstructions around fans. Sometimes simple cleaning fixes what looks like a major problem. Worn door seals also disrupt airflow patterns.

Hot spots turn perfect batches into sorting nightmares. Temperature mapping with a basic oven thermometer reveals problem areas quickly. Most hot spots indicate failing heating elements that need professional attention.

Steam leaks rob your bread of perfect crust while wasting energy. Check door seals first - they're the most common culprit. Steam injection systems also develop leaks over time.

Conveyor jams in tunnel systems usually happen at the worst moments. Regular cleaning prevents most product buildup issues, while proper belt tracking keeps everything running smoothly.

Control errors sound scary but often have simple solutions. Modern ovens display diagnostic codes that take the guesswork out of troubleshooting. Keep your manual handy - many "mysterious" problems have obvious fixes.

Innovation Spotlight & Emerging Trends

The world of industrial ovens for baking is experiencing a technological revolution that's making bakery operations smarter, more efficient, and surprisingly intuitive.

IoT monitoring systems have transformed ovens from standalone equipment into connected intelligence hubs. Your oven can now send text alerts when it needs attention, track energy usage, and compare performance to industry benchmarks.

AI-powered bake curves learn from every batch you produce. These systems observe how your specific products behave in your unique environment and adjust temperature and timing to deliver consistent results, even when conditions change.

Predictive maintenance takes the guesswork out of equipment care. Sensors monitor component health and predict when parts will need replacement. This approach has helped many bakeries reduce unexpected downtime by up to 40%.

Heat-to-product sensors monitor the actual temperature inside your bread loaves or pastries, not just the oven chamber. This precision eliminates guesswork and ensures perfect doneness every time.

For deeper insights into these emerging technologies, scientific research on hybrid ovens explores the latest developments in heating methods and control systems.

How Technology Is Redefining Industrial Ovens for Baking

Cloud analytics aggregate performance data from all your equipment, revealing patterns you might never notice otherwise. A bakery chain recently found that their most efficient location was using slightly different temperature profiles - insights they quickly applied across all stores.

Remote diagnostics have revolutionized equipment service. When issues arise, technicians can often diagnose and resolve problems without leaving their office. Many software glitches and calibration issues can be fixed instantly through guided procedures.

Adaptive airflow systems continuously adjust fan speeds and air circulation patterns based on what you're baking and how much product is loaded. Your first tray of cookies bakes exactly like your twentieth.

Carbon tracking dashboards help bakeries understand and reduce their environmental impact. These systems measure energy consumption and translate it into carbon footprint data while suggesting specific improvements.

Frequently Asked Questions about Industrial Ovens for Baking

What Size Industrial Oven Do I Need?

The right oven size comes down to understanding your busiest production periods and planning for growth. Calculate your peak hourly output and size your equipment for about 20-30% above that capacity.

Different products require different oven time. A pizza oven might produce 60 pizzas per hour at high heat, but artisan loaves need 45 minutes or more per batch. Factor this into your calculations.

Countertop units with 0.8-2.1 cubic feet work for testing recipes or small specialty batches. Single rack ovens accommodate 5-10 sheet pans and suit smaller bakeries. Double rack ovens handle 10-20 sheet pans, while conveyor ovens get sized by belt dimensions. Tunnel ovens are custom-built for massive operations.

Are Electric Industrial Ovens Cheaper to Operate Than Gas?

This depends on your local utility rates, which vary wildly across the country. In many regions, natural gas delivers lower operating costs per BTU. However, modern electric infrared systems can be up to 50% more energy efficient than gas convection units, potentially flipping the cost equation.

Real factors affecting monthly bills include local gas and electric rates, insulation quality, operating hours, and maintenance needs. Gas systems often need more ventilation work and regular burner adjustments, while electric units typically require less hands-on maintenance.

We recommend running total cost of ownership numbers - purchase price, installation, energy costs, and maintenance over the equipment's expected lifespan.

How Often Should I Schedule Professional Oven Maintenance?

Most units thrive with quarterly professional service, but heavy-use operations might need monthly attention. Quarterly service includes comprehensive inspection, calibration, cleaning of hard-to-reach components, and control adjustments. This typically runs 2-4% of your oven's purchase price annually.

Monthly service makes sense for ovens running 16+ hours daily or handling multiple product types. Annual service should include major component inspection and replacement of wear items like gaskets, belts, and heating elements.

Regular professional maintenance costs far less than emergency repairs during busy service periods. Well-maintained industrial ovens for baking hold their value better and deliver more consistent results.

Conclusion

Choosing the right industrial oven for baking sets the stage for everything that follows in your bakery operation. Your oven becomes the heartbeat of your business - getting it right the first time saves countless headaches down the road.

Quality industrial ovens for baking might require a bigger upfront investment, but they deliver consistent results, lower operating costs, and fewer emergency repair calls. The sweet spot lies in balancing immediate needs with future possibilities.

Energy efficiency deserves special attention with climbing utility costs. Modern industrial ovens for baking with dual-fuel capabilities or advanced insulation systems often pay for themselves within the first year through energy savings alone.

Don't overlook the human factor. Equipment that's easy to clean and maintain keeps your staff happier and more productive. Complex systems requiring specialized technicians for minor issues can drain your budget quickly.

At The Restaurant Warehouse, our wholesale pricing approach means you're not paying inflated retail markups or sales commissions. That extra money stays in your pocket for higher-quality equipment that actually supports your goals.

The bakery industry continues evolving with smart controls, predictive maintenance, and energy recovery systems becoming standard features. Investing in equipment that accepts these innovations positions your operation for long-term success.

Your oven choice ripples through every aspect of your operation - product quality, production speed, energy costs, and staff satisfaction all trace back to this fundamental decision. Take time to evaluate thoroughly and choose equipment that serves your vision.

Ready to explore your options? Our Restaurant Oven for Sale Guide walks you through additional considerations and product recommendations to help make your next equipment investment a confident one.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment