Industrial Meat Slicer The Complete Operator's Guide

Step into the world of high-volume food production, and you'll quickly realize that the slicer at your local deli counter just won't cut it. An industrial meat slicer is a whole different beast—a powerhouse engineered for relentless speed, razor-sharp precision, and the kind of endurance needed in a commercial setting. These machines are built to slice literally thousands of pounds of meat with absolute consistency, making them the unsung heroes in meat processing plants, large-scale delis, and food manufacturing facilities. Unlike their smaller cousins, these slicers are designed for continuous, often automated, operation.

The Backbone of High-Volume Food Production

Once you move past the scale of a neighborhood shop, manual slicing becomes an impossible bottleneck. Industrial meat slicers obliterate that problem, transforming a slow, labor-intensive task into a streamlined, automated process. It's helpful to think of them less as a simple cutting tool and more as a precision instrument—almost like a CNC machine, but for food.

These machines are the workhorses of the food supply chain, ensuring every package of salami, ham, or turkey you see at the grocery store contains slices of perfectly uniform weight and thickness. That consistency isn't just for looks; it's absolutely critical for portion control, packaging efficiency, and maintaining brand quality.

Power and Precision Combined

What really sets an industrial meat slicer apart is its incredible blend of raw power and delicate control. A heavy-duty motor drives a massive, razor-sharp blade through large logs of meat, while sophisticated controls dictate the exact thickness, slicing speed, and even how the final product is stacked. For any business where output is measured in tons instead of pounds, this capability is non-negotiable.

Here’s what these machines bring to the table:

- Continuous Operation: They're built with rugged, durable components that allow them to run for hours on end without overheating or losing performance.

- Uniform Slicing: They produce flawlessly consistent slices, which is vital for managing food costs and guaranteeing a top-quality product every time.

- Enhanced Safety: Industrial models are packed with advanced safety features, like robust blade guards and emergency stops, to protect operators in a fast-paced environment.

At its core, an industrial meat slicer is a critical investment in efficiency. It directly addresses labor shortages, reduces product waste, and boosts overall productivity, making it indispensable for growth-focused food processors.

A Growing Market Driven by Demand

The importance of this equipment is clearly reflected in its market growth. The industrial meat slicer market is projected to hit USD 510.4 million in 2025 and is expected to keep growing at a strong CAGR of 9.8% through 2033. This surge is fueled by the rising global demand for processed foods, a bigger push for automation in food plants, and stricter food safety standards that require hygienic, high-performance equipment.

Getting a handle on the fundamentals of these machines is the first step toward optimizing your production line. While this guide is focused on industrial-scale models, our broader meat slicer machine guide can provide extra context on the different types of slicers available for various commercial needs.

Exploring Different Types of Industrial Slicers

Picking the right industrial meat slicer feels a lot like choosing the perfect engine for a vehicle. The goal is always to move forward, but the best engine depends entirely on whether you're driving a city car, a delivery van, or a long-haul truck. The world of industrial slicers is much the same—it’s divided into distinct categories, each engineered for a specific scale and purpose.

Getting a handle on these differences is the key to matching the machine to your mission. The main distinction comes down to how they operate, which directly impacts your output, labor costs, and how much control you have over every slice. Let's break down the three main types to see where they fit best.

The Manual Slicer: The Artisan's Choice

Manual industrial slicers are the foundation of slicing technology, offering the ultimate in operator control. You’ll often hear them called gravity-feed slicers, and they require a person to physically push the product carriage back and forth across the spinning blade. While a motor powers the blade, the slicing action itself is entirely human-driven.

This hands-on approach is perfect for smaller, specialized operations where precision and adaptability matter more than sheer volume. Think of an artisanal charcuterie shop slicing delicate prosciutto or a high-end deli that needs to switch between different meats on a dime.

- Total Operator Control: The user dictates the speed and pressure of each slice, allowing for adjustments on the fly.

- Lower Initial Cost: They are generally the most affordable way to get into the industrial slicer game.

- Versatility for Small Batches: Perfect for businesses that don't need continuous, high-speed output.

But because they rely so heavily on manual labor, they just can't keep up in large-scale production where speed and absolute consistency are everything.

The Semi-Automatic Slicer: A Balance of Power and Precision

The semi-automatic industrial meat slicer is a serious step up in efficiency. These machines have a motorized carriage that automatically moves the product across the blade at a consistent, preset speed. The operator's job shifts from the physically demanding work of pushing to simply loading the product, setting the parameters, and catching the finished slices.

This design strikes a fantastic balance between automation and human oversight. It’s the perfect fit for high-volume delis, large catering kitchens, and commissaries that need to produce hundreds of pounds of sliced meat per day but aren't ready for a fully automated system.

A semi-automatic slicer frees up the operator from the most physically demanding part of the job. This dramatically increases output and reduces fatigue while still allowing for direct quality control.

The demand for this type of equipment is growing as businesses look to boost their efficiency. The global industrial food slicers market, which includes these powerful machines, was valued at around USD 0.6 billion in 2025 and is projected to hit USD 1.3 billion by 2035, growing at a brisk 8.0% CAGR. This growth really highlights the industry's shift toward more productive and precise slicing solutions. You can dive deeper into the numbers with this full market analysis on industrial food slicers.

The Fully Automatic Slicer: The Apex of Production

At the top of the pyramid, you'll find the fully automatic industrial meat slicer. These aren't just slicers; they're complete production systems, often integrated with conveyor belts for feeding product in and moving finished portions out. The entire process—from loading the meat log to slicing, shingling, stacking, and portioning—is automated.

These machines are the heart and soul of large-scale meat processing plants and facilities that supply pre-packaged deli meats to supermarkets. They are built for continuous, high-speed operation and can slice and package thousands of portions per hour with minimal human help.

Their advantages are crystal clear:

- Maximum Throughput: Unmatched slicing speed and volume, which is essential for mass production.

- Labor Reduction: Significantly cuts down on the number of staff needed for the slicing line.

- Ultimate Consistency: Programmable controls ensure every single slice and portion is identical—a must for cost control and brand standards.

The trade-off, of course, is a much higher initial investment and a larger physical footprint. But for any operation that measures its output in tons, a fully automatic industrial meat slicer isn't just an option—it's a necessity for staying competitive.

To make things even clearer, let's look at how these three types stack up against each other.

Industrial Meat Slicer Types At-a-Glance

| Slicer Type | Operation Mode | Ideal Application | Typical Output (Slices/Hour) | Key Advantage |

|---|---|---|---|---|

| Manual | Operator pushes carriage | Artisanal shops, low-volume delis | 100 - 500 | Total control and precision |

| Semi-Automatic | Motorized carriage, manual loading | High-volume delis, catering kitchens | 1,500 - 3,000 | Balances speed with oversight |

| Fully Automatic | Integrated system with conveyors | Large-scale processing plants | 5,000+ | Maximum throughput and consistency |

Each type has its place, and choosing the right one really comes down to understanding your own production needs, labor resources, and long-term business goals.

Anatomy of a High-Performance Slicer

To really get what makes an industrial slicer tick, you’ve got to look under the hood. Past the shiny stainless steel, there's a whole system of components engineered to work in perfect harmony. Think of it like a mechanic checking out a high-performance engine; every single part is chosen for its ability to deliver power, precision, and endurance under pressure.

Going beyond the sales pitch and understanding the actual engineering is what separates a smart purchase from an expensive mistake. When you know how the blade, motor, and carriage work together, you can translate a spec sheet into real-world benefits for your operation. It’s how you make sure you’re investing in a machine that actually delivers.

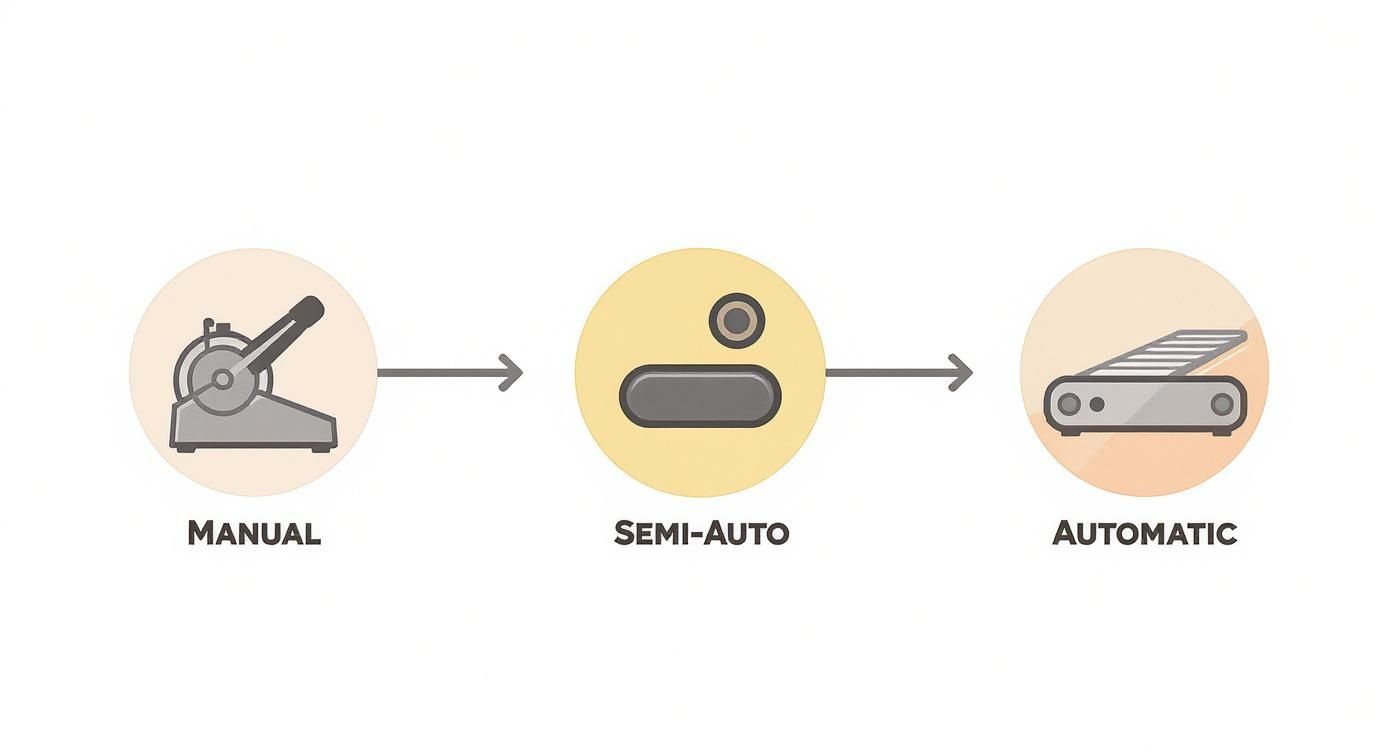

Before we dive into the guts of the machine, this infographic gives a great overview of how slicers operate, setting the stage for the parts that power them.

This shows the evolution from full hands-on control to complete automation—a change driven by the relentless need for more speed and consistency in food production.

The Blade: The Heart of the Machine

If you ask me, the blade is the single most critical part of any industrial slicer. Its size, what it’s made of, and the type of edge it has will directly control your slice quality, consistency, and even what kinds of products you can run through it.

A bigger blade diameter, usually somewhere between 12 to 14 inches (or even larger), lets the machine tackle bigger logs of meat, which means higher throughput. The material is just as critical; high-carbon stainless steel is the gold standard because it’s tough and holds a razor-sharp edge for a long, long time.

The edge itself is usually tailored for specific jobs:

- Smooth Edge: This is what you'll see most often. It’s perfect for slicing lean meats like turkey and cooked ham, giving you a clean, precise cut without any tearing.

- Serrated Edge: This one is built for tougher products or those with a crust, like a hard salami or rustic bread. The little teeth grip the product, stopping it from slipping and ensuring a clean slice every time.

Motor and Drive System: The Powerhouse

If the blade is the heart, then the motor is the engine driving the whole operation. The motor's power, measured in horsepower (HP), determines the slicer's cutting force and whether it can muscle through dense products without stalling or overheating. A heavy-duty industrial slicer will typically have a motor from 1/2 HP to 1 HP, sometimes more.

A more powerful motor isn't just about speed; it's about endurance. It ensures the slicer can run continuously for hours, slicing through dense or semi-frozen products without straining, which is essential for preventing downtime in a high-volume plant.

The drive system is what gets that power to the blade. In top-tier machines, you’ll almost always find gear-driven systems. They deliver more torque and are far more durable than belt-driven systems, which will eventually need their belts replaced.

The Carriage and Product Tray: The Work Surface

The carriage is the part that holds the meat and guides it across the blade. Its size dictates the biggest product log you can slice. A bigger carriage—often called a product tray or table—is a must if you're working with oversized logs of meat or cheese.

This is also a key component for operator safety and efficiency. Things like a locking mechanism that holds the carriage steady during cleaning are totally non-negotiable. The smoothness of the carriage's glide, whether you're pushing it by hand or it's motorized, also makes a big difference in slice quality and reduces operator fatigue.

Advanced Features: Driving Modern Efficiency

Today’s industrial slicers are way more than just a motor and a blade. The best ones are packed with advanced tech that automates tasks, slashes waste, and cuts down on manual labor. These are the features that truly separate a good slicer from a great one.

Here are a few game-changing innovations to look for:

- Integrated Scales: These systems weigh each portion as it's sliced. You get perfect portion control every single time, which puts a stop to costly product giveaway.

- Automatic Stacking and Shingling: The fully automatic models can arrange slices into neat stacks or overlapping shingled portions, getting them ready for immediate packaging. No hands required.

- Programmable Controls: Operators can use a digital interface to save "recipes" for different products. You can program the exact slice thickness, speed, and portion counts, guaranteeing absolute consistency no matter who is running the machine.

These kinds of features transform the slicer from a simple cutting tool into a central piece of your production line, driving both efficiency and profit.

How to Choose the Right Industrial Meat Slicer

Picking out an industrial meat slicer isn't like buying a small appliance; it's a major capital investment. Get it right, and you’ll boost production efficiency, cut down on labor costs, and improve your product quality for years to come. Get it wrong, and you're stuck with a costly bottleneck.

The key is to move past the sticker price and really dig into your specific operational needs. It all starts with a clear-eyed analysis of your daily workflow. Before you even glance at a single model, you need solid answers about how you operate. Nailing this part is the foundation for a smart purchase.

Analyzing Your Production Needs

First things first, you have to get a handle on your output. You need to know exactly how much product you're slicing and how fast it needs to happen. An honest assessment here is crucial—it keeps you from overspending on a machine with way more capacity than you need or, even worse, buying a slicer that can’t keep up with demand.

Start by asking these critical questions:

- What's your daily production volume? And be specific. Are we talking 500 pounds a day or 5,000? This number alone will steer you toward either semi-automatic or fully automatic systems.

- What types of products will you slice? The density and texture of the meat make a huge difference. Slicing delicate, cooked turkey breast requires a completely different blade and motor than processing dense, hard salami or semi-frozen logs.

- What are your facility's constraints? Grab a tape measure and figure out your available floor space. An automatic, conveyor-fed industrial slicer takes up a serious amount of room that a smaller facility might not have.

Answering these questions gives you a clear operational profile, pointing you toward a machine that’s actually built for your specific environment. For some extra insight into different models, check out our guide on the best meat slicers for various commercial needs.

Looking Beyond the Purchase Price

One of the most common mistakes I see is people getting fixated on the initial cost. The true expense of an industrial slicer is its total cost of ownership (TCO), which covers all the operational costs over its entire lifespan. A machine that seems cheaper today might end up costing you a fortune in high energy bills, frequent downtime, and expensive repairs.

The growth in this market really highlights why TCO is so critical. The global industrial meat slicer market was valued at USD 496 million in 2023 and is expected to hit USD 963.3 million by 2030, growing at an incredible 10.2% CAGR. This boom is driven by new tech that improves efficiency and lowers long-term costs.

To get a real sense of a slicer's TCO, look at its energy consumption (seek out energy-efficient motors), the expected lifespan and replacement cost of the blade, and how often it needs routine maintenance. A durable, gear-driven model might cost more upfront, but it could save you thousands in belt replacements and service calls down the road.

Prioritizing Safety and Sanitation

In any commercial food operation, safety and sanitation are absolutely non-negotiable. An injury or a foodborne illness outbreak can be catastrophic for both your team and your brand. That’s why features that protect your operators and make cleaning easier aren't luxuries—they're essential requirements.

As you evaluate different machines, keep an eye out for these critical features:

- NSF Certification: This is the gold standard. It’s your assurance that the slicer is designed and built to promote food safety, with smooth, easy-to-clean surfaces and no hidden spots where bacteria can thrive.

- Blade Guards and Interlocks: A permanent ring guard should protect the non-cutting edge of the blade at all times. You’ll also want safety interlocks that prevent the machine from running if key parts are removed for cleaning.

- Emergency Stop Buttons: These need to be big, red, and right where the operator can hit them instantly to shut the machine down in an emergency.

- No-Volt Release: This is a crucial safety mechanism. It prevents the slicer from automatically restarting after a power outage, protecting an operator who might be in the middle of cleaning or servicing the machine.

By systematically working through your production volume, calculating the total cost of ownership, and making safety a top priority, you can confidently choose an industrial meat slicer that's a perfect fit for your budget, your workflow, and your team.

Safe Operation, Cleaning, and Maintenance

An industrial meat slicer is a serious piece of machinery. Just like any high-performance equipment, its lifespan and the quality of what it produces depend entirely on how well you treat it. Getting into a solid rhythm of proper operation, strict cleaning, and proactive maintenance isn't just about following best practices—it’s about protecting your food, your team, and your investment.

Think of it this way: mastering this daily, weekly, and monthly routine is what turns your slicer from a simple tool into a dependable powerhouse for your production line.

It all starts with treating the machine with the respect it deserves. Safe operation is the absolute foundation. This means understanding exactly what the machine can do and sticking to safety rules that protect operators from that powerful motor and razor-sharp blade. Even a tiny slip-up can create a major risk.

Mastering Safe Slicer Operation

Before anyone even thinks about making a slice, they need to be thoroughly trained. This goes way beyond knowing how to flip the "on" switch. It means having a deep understanding of the slicer's specific features, from dialing in the slice thickness to knowing exactly where every emergency stop button is located.

Safe operation involves a few key habits:

- Pre-Flight Check: Always start with a quick visual inspection. Make sure all the guards are locked in place, the carriage glides smoothly, and the blade is clear of any gunk from the last cleaning.

- Load It Right: Secure the meat firmly on the product tray. If the product is wobbly, it can shift during slicing, leading to uneven cuts and creating a potential hazard.

- Eyes on the Machine: Never, ever walk away from a running slicer. The operator should be watching for any changes in performance, listening for odd sounds from the motor, and keeping an eye on the quality of the slices coming off the blade.

To make sure your operations are fully compliant and safe, it's a good idea to be familiar with the relevant Australian workplace safety standards. These guidelines provide a solid framework for creating a secure work environment around heavy machinery.

The Non-Negotiable Cleaning Protocol

Cleaning an industrial meat slicer is one of the most critical jobs in any food facility. If it's not done right, you risk cross-contamination and the growth of nasty bacteria like Listeria, which is a serious threat to public health. A meticulous, step-by-step approach isn't optional—it's essential.

The rule is simple: clean and sanitize the slicer at least once every four hours of continuous use, and always when switching between different types of products. This isn't just a suggestion; it's a core food safety requirement.

The process needs to be systematic and safe:

- Kill the Power: Always unplug the slicer completely before you start cleaning. The no-volt release is a great safety net, but physically pulling the plug is the only way to be 100% sure it's safe.

- Take It Apart: Carefully remove the product tray, blade guard, and any other parts designed to be taken off for cleaning. Always wear cut-resistant gloves when you're handling the blade or any parts near it.

- Wash, Rinse, Sanitize: Use the classic three-sink method for all removable parts. Wash them with soap and hot water, give them a thorough rinse with clean water, and then let them soak in a food-grade sanitizing solution as directed by the manufacturer.

- Clean the Body: Meticulously clean the body of the slicer. Pay extra attention to seams, joints, and the area around the blade housing where food particles love to hide.

- Air Dry and Reassemble: Let every part air dry completely before putting the slicer back together. This prevents moisture from getting trapped, which can create a breeding ground for bacteria.

For a deeper dive into best practices, our guide on cleaning restaurant equipment offers valuable tips that apply to your entire kitchen.

Proactive Maintenance for Peak Performance

Finally, let's talk about what keeps your slicer running like a champ for years: proactive maintenance. Waiting for a part to break is a recipe for expensive downtime and lost production. A structured maintenance schedule lets you catch small issues before they snowball into big problems.

Key tasks include lubricating moving parts, checking belts for wear, and—most importantly—keeping that blade sharp. A dull blade doesn't slice; it tears and shreds meat, which increases waste and puts a ton of unnecessary strain on the motor.

Here’s a simple schedule to keep your slicer in top condition. Sticking to a routine like this is the best way to protect your investment and get consistent results, day in and day out.

Industrial Slicer Maintenance Schedule

| Frequency | Task | Purpose |

|---|---|---|

| Daily | Wipe down the exterior, check guards, ensure safety features are functional. | Maintains basic hygiene and confirms the machine is safe for operation. |

| Weekly | Lubricate the carriage slide rods and other moving parts as per the manual. | Ensures smooth, effortless operation and reduces wear and tear on components. |

| Monthly | Inspect the drive belt for signs of cracking or fraying. | Catches potential belt failure before it causes a breakdown during a shift. |

| As Needed | Sharpen the blade using the built-in or a separate sharpener. | Guarantees clean, consistent slices, reduces product waste, and lessens motor strain. |

Following a consistent maintenance plan isn't a chore; it's insurance. It ensures your slicer remains a reliable and efficient part of your operation for the long haul.

Answering Your Top Slicer Questions

Even when you've got a good handle on your industrial meat slicer, questions pop up. It's only natural. These are powerful, complex machines, and knowing how to handle the day-to-day situations that come up can save you a ton of time, cut down on waste, and, most importantly, keep everyone safe.

Think of this section as your go-to cheat sheet for those "what if" moments. I've pulled together the most common questions we hear from operators and kitchen managers to give you clear, straight-to-the-point answers you can use right away.

How Often Should I Sharpen My Industrial Slicer Blade?

This is easily one of the most critical maintenance questions. A sharp blade is everything. When it gets dull, you don't just get sloppy slices; you're also putting a massive strain on the slicer's motor and creating a real safety hazard. But there's no single magic number for how often to sharpen.

It really boils down to two things: your daily usage and the types of products you're slicing. If you're a high-volume spot running your slicer for eight or more hours a day, sharpening it weekly is a great place to start. For lighter use, you might find that every two weeks or even once a month does the trick.

Here’s the real pro tip: let the slicer tell you when it’s time. If you start seeing shredded edges, torn meat, or more product sticking to the blade, don't wait. That's your slicer screaming for a sharpening. Ignoring it just leads to more waste and a product that doesn't look its best.

And always, always use the built-in sharpener that came with your machine. It's designed specifically for that blade, making it the safest and most effective way to get that razor-sharp edge back.

Can I Slice Frozen Meat with My Slicer?

This is a big one, and getting it wrong can be a costly mistake. The short answer is: it completely depends on the slicer. The vast majority of standard industrial meat slicers are built to handle chilled, fresh meat. Trying to force a rock-hard block of frozen meat through one of these is just asking for trouble.

You're risking some serious damage, including:

- Chipping or shattering the blade: Frozen meat is incredibly hard and can easily break the fine, precision edge of a standard blade.

- Burning out the motor: The motor will have to work overtime to push the blade through something it wasn't designed for, which can lead to overheating and total failure.

- Creating a major safety risk: The frozen block can slip, jump, or even shatter, creating a dangerous and unpredictable situation for the operator.

Now, there are specialized slicers out there built for exactly this. These heavy-duty beasts have more powerful motors, beefier components, and blades designed to power through tempered or semi-frozen products. If you absolutely need to slice frozen meat, you must invest in a machine that is explicitly designed for that job. When in doubt, check the manual.

What Is the Difference Between Belt-Driven and Gear-Driven?

The drive system is what gets the power from the motor to the blade, and there are two main types you'll see: belt-driven and gear-driven. A belt-driven slicer works a lot like the fan belt in your car, using a tough, durable belt to connect the motor and blade. It’s a common, reliable design, but that belt is a wearable part that will need replacing eventually.

A gear-driven slicer, however, uses a set of interlocking metal gears to transfer power directly. This setup is a real game-changer in a heavy-use industrial environment.

| Feature | Gear-Driven System | Belt-Driven System |

|---|---|---|

| Power Transfer | Direct and powerful, with more torque. | Can sometimes slip under a very heavy load. |

| Durability | Extremely tough with fewer parts that wear out. | The belt will eventually stretch and need replacing. |

| Best For | Heavy-duty, nonstop use with dense cheeses. | General daily use in moderate to high-volume spots. |

| Maintenance | Lower maintenance, with no belts to worry about. | Belts need to be checked and replaced periodically. |

Because they are so powerful and reliable under constant stress, you'll typically find gear-driven systems in the higher-end, heavy-duty industrial slicers. They’re the top choice for any operation that’s slicing tough products or running the machine for hours on end, day after day.

What Are the Most Important Safety Features to Look For?

When we're talking about a machine with a spinning blade this sharp and powerful, you can't afford to cut corners on safety. The features that protect your team are absolutely non-negotiable. A great starting point is to look for certifications like NSF, which tells you the machine meets tough standards for public health and safety.

Beyond that, here are four essential safety features you should insist on:

- Permanent Ring Guard: This is a fixed guard that stays on the non-slicing part of the blade at all times. Even when you take other guards off for cleaning, this one stays put to protect you.

- No-Volt Release: This is a crucial one. If the power goes out, this feature prevents the slicer from just starting back up on its own when the power comes back. Someone has to physically press the "on" button again, which prevents nasty surprises during cleaning or maintenance.

- Carriage and Blade Locks: A good slicer should have a way to lock the product tray (the carriage) so it doesn't move when you're not using it. You also need solid blade guards that completely cover the edge when you're cleaning or servicing the machine.

- Accessible Emergency Stop: Look for a big, obvious E-stop button that's easy to reach. If anything goes wrong, your operator needs to be able to slap that button and shut the machine down instantly.

Making these features a priority means you’re getting a machine that not only works great but also helps create a safer kitchen for your entire team.

Ready to equip your kitchen with the right tools for success? The Restaurant Warehouse offers a wide selection of commercial-grade equipment designed for performance and reliability. Explore our catalog and find the perfect solutions for your business today at https://therestaurantwarehouse.com.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment