Top Industrial Food Processors Buying Guide | Optimize Your Kitchen

Here's the rewritten section, designed to sound like it was written by an experienced human expert.

Think of an industrial food processor as your kitchen's MVP—the one employee who works at superhuman speed, delivers perfectly consistent cuts every single time, and never calls in sick. These machines are the heavy-duty workhorses that bridge the gap between a standard countertop appliance and a full-blown factory production line, giving professional kitchens the power to ramp up production without ever sacrificing quality.

Why Your Kitchen Needs an Industrial Food Processor

In any high-volume kitchen, manual prep is the number one bottleneck. It’s just a fact. Chopping, slicing, dicing, and mixing by hand isn't just slow and exhausting for your team; it’s also a recipe for inconsistency. An industrial food processor completely shatters that limitation, acting as a true force multiplier for your kitchen staff.

Imagine you need to prep 50 pounds of onions for your mirepoix base. For a skilled prep cook, that's easily an hour of teary-eyed work, resulting in cuts that are "close enough" and a significant chunk of your labor budget. With a continuous-feed industrial processor, that same job is done in under five minutes. And the results? Perfectly uniform, every single time.

The Pillars of a Smarter Kitchen

This incredible jump in productivity really comes down to three core benefits that have a direct impact on your bottom line. Investing in the right machine isn't just buying equipment; it's a strategic move that pays you back through speed, consistency, and sheer versatility.

- Unmatched Speed: These processors are engineered for bulk work, capable of handling hundreds—or even thousands—of pounds of product per hour. This slashes prep time, freeing up your skilled staff to focus on more complex, creative tasks that actually add value to the plate.

- Perfect Consistency: From perfectly shredded cheese for your pizzas to silky-smooth puréed sauces, an industrial processor delivers identical results with every batch. This is absolutely critical for recipe accuracy, portion control, and upholding the high-quality reputation your customers expect.

- Expansive Versatility: With a whole arsenal of interchangeable blades and discs, a single machine can do the work of a dozen hands. It can slice tomatoes, grate carrots, knead dough, emulsify dressings, and grind meats, making it one of the most adaptable tools you can have in your kitchen.

The real value of an industrial food processor isn't just about doing things faster. It's about creating a more efficient, predictable workflow. It transforms your prep process from a variable labor cost into a fixed, highly efficient system.

A Strategic Investment in Growth

Ultimately, bringing an industrial food processor into your kitchen is about more than just a new piece of hardware. It’s a fundamental shift in how you operate. By automating the most repetitive, time-sucking prep work, you unlock a whole new level of efficiency and capacity.

This is what allows you to scale your menu, serve more customers, and even reduce food waste by using ingredients more effectively. So instead of seeing it as just another expense, think of it as a strategic investment in your kitchen's future growth and profitability. Understanding that value is the first step toward choosing the right model to completely transform your operation.

Decoding the Different Types of Food Processors

Choosing an industrial food processor is a lot like picking the right knife for a specific task in the kitchen. You wouldn't use a cleaver for delicate brunoise, right? Similarly, the machine that creates silky-smooth pâté is worlds apart from the one you need to shred 200 pounds of cabbage for a weekend's worth of coleslaw. Getting to know the distinct categories is the first real step toward making a smart investment.

Each type of processor is engineered for a very specific job. The key is to match the machine's strengths to your menu's demands—that’s how you max out efficiency and get the consistent results your customers expect every single time. Let’s break down the main players in the world of industrial food processors.

Bowl Cutters: The Emulsifying Champions

Often called Buffalo Choppers, bowl cutters are the undisputed masters of mixing, grinding, puréeing, and, most importantly, emulsifying. Picture a rotating bowl that constantly feeds ingredients into a set of high-speed spinning knives. This unique design is the secret to creating incredibly smooth textures from both solid and liquid ingredients.

Think about making large batches of hummus, pesto, or sausage filling. The bowl cutter’s action is what thoroughly combines fats, liquids, and solids into a stable, uniform mixture—something that’s just about impossible to do by hand or with less specialized equipment. Its enclosed bowl design is also perfect for containing liquids and creating those perfectly bound emulsions.

- Best For: Creating smooth purées, emulsified dressings, pâtés, meat fillings, and sauces.

- Key Function: A rotating bowl and fixed, high-speed knives work in tandem to chop and mix ingredients simultaneously.

- Capacity: Measured by bowl size in quarts, they are designed for batch processing, not continuous output. Models range from smaller 15-quart units to massive 80-quart floor machines.

Continuous Feed Processors: The Volume Kings

When high-volume prep work is the name of the game, the continuous feed processor reigns supreme. Unlike a bowl cutter that works in batches, this machine is built for non-stop action. You feed raw product into a chute at the top, and the processed food is instantly ejected from another opening, ready to be collected.

This is the machine you need for slicing mountains of potatoes for fries, dicing onions for salsa, or shredding lettuce for thousands of salads. It’s a true prep line automator. Tasks that used to take a team of prep cooks hours can be done in minutes with incredible precision. A mid-range model, for instance, can easily process over 1,200 pounds of vegetables per hour.

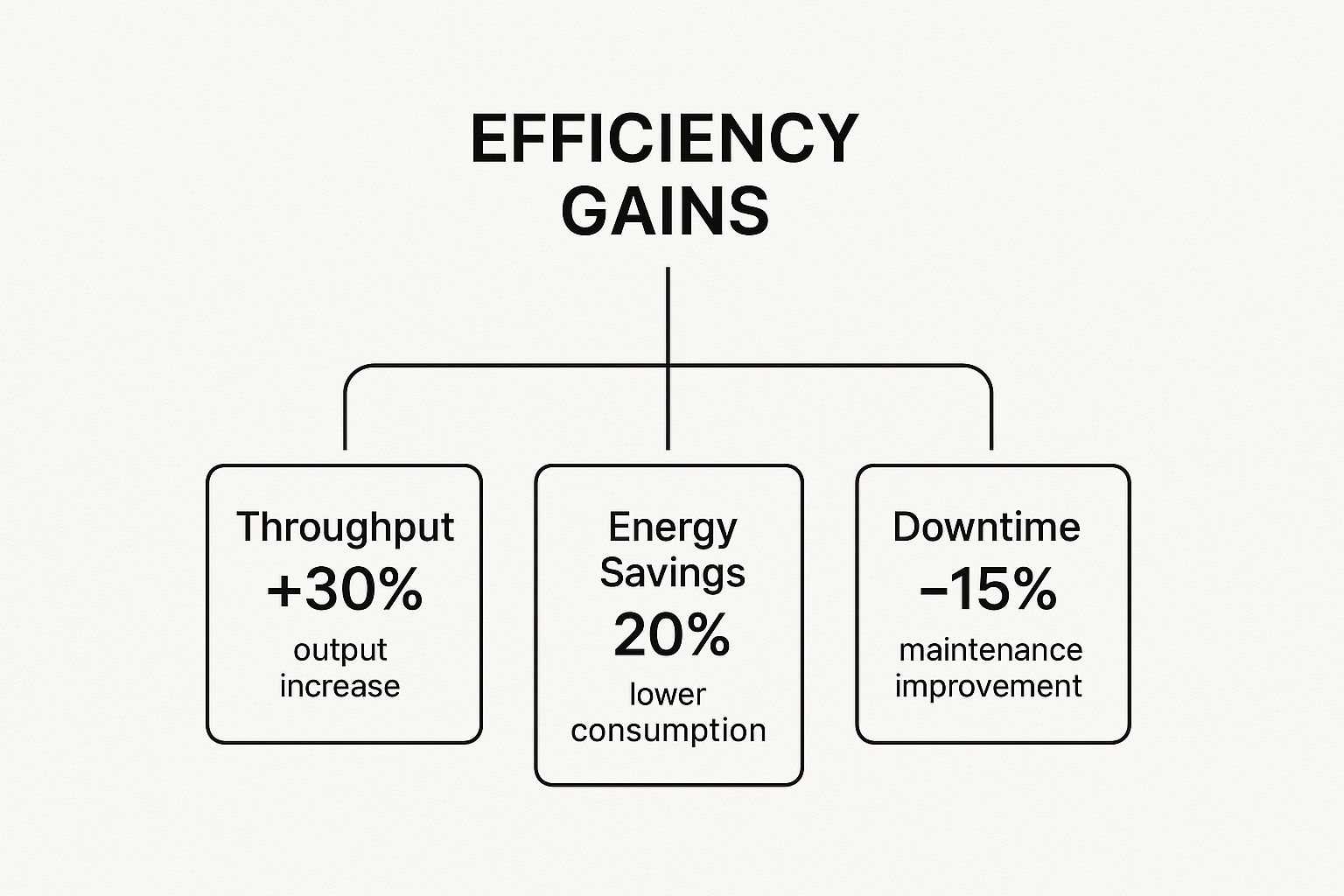

The data above shows just how much of a difference the right equipment can make, leading to measurable improvements in how much you can produce, how much energy you use, and how reliable your whole operation is.

To give you a clearer picture of how these machines stack up, here’s a quick side-by-side look.

A Quick Comparison of Industrial Food Processor Types

| Processor Type | Primary Function | Ideal Applications | Key Feature |

|---|---|---|---|

| Bowl Cutter | Emulsifying, mixing, puréeing | Hummus, pesto, sausage, pâté | Rotating bowl with fixed, high-speed knives for batch work. |

| Continuous Feed | Slicing, dicing, shredding | Coleslaw, French fries, salsa | Non-stop processing with separate input and output chutes. |

| Vertical Cutter Mixer | Heavy-duty mixing, kneading, cooking | Dense doughs, thick batters, soups | Large, stationary bowl with powerful bottom blades; can cook. |

This table helps illustrate that the best choice really comes down to what you're making and how much of it you need to produce.

Vertical Cutter Mixers: The Hybrid Powerhouses

So, what if you need the intense chopping power of a bowl cutter but on a much larger scale, with the ability to cook ingredients at the same time? That’s where the Vertical Cutter Mixer (VCM) comes in. Think of a VCM as a bowl cutter on steroids—it combines a large, stationary mixing bowl with incredibly powerful blades at the bottom.

VCMs are designed for heavy-duty, large-volume tasks that often involve heat. They can knead dense doughs, mix thick batters, and even cook soups or sauces directly in the bowl, thanks to available steam-jacketed models.

Their raw power and sheer size make them indispensable in large-scale operations like central commissaries, bakeries, and institutional kitchens. A 40-quart VCM, for example, can mix enough dough for hundreds of loaves of bread in a single go. Their versatility allows them to handle an incredible range of tasks, from chopping vegetables to mixing huge batches of salad dressing.

Ultimately, choosing the right type of industrial food processor boils down to a simple analysis of your menu and production needs. Do you need to create perfectly emulsified sauces in batches? A bowl cutter is your answer. Do you need to process hundreds of pounds of produce every single day? A continuous feed model is non-negotiable. And for those massive, multi-step recipes, a VCM provides unmatched power and versatility.

Must-Have Features for Modern Processors

Once you’ve figured out the type of food processor that fits your operation, the real work begins. This is where you dig into the details that separate a true kitchen workhorse from a machine that just causes headaches. Moving past the sales pitch means having a solid checklist of what actually delivers performance, safety, and a long life on the prep line.

These features aren't just nice extras; they are the core of what makes a processor a valuable asset. The right blend of power, solid construction, and smart design can make a machine indispensable. Get it wrong, and you've just created a new bottleneck in your kitchen.

The Powerhouse Motor

The motor is the absolute heart of any food processor. Its power, measured in horsepower (HP), determines what the machine can realistically handle. It's the difference between a unit that plows through dense blocks of parmesan and one that groans, overheats, and eventually gives up the ghost.

Think of it like picking an engine for a work truck. A small engine might be fine for light errands, but it’s going to struggle and wear out fast if you’re hauling heavy loads uphill all day. In the same way, a low-horsepower motor can handle soft vegetables, but it's just not cut out for thick doughs or the grind of continuous, all-day use.

For any serious, daily use in a commercial kitchen, you should be looking for a motor with 3 HP or higher. This ensures the processor has enough torque to muscle through tough ingredients without burning out, which protects your investment and prevents frustrating downtime during a busy service.

Durability and Construction Quality

A commercial kitchen is a tough place to work, and your equipment has to be built to match. It needs to stand up to constant use, heavy-duty cleaning, and the general chaos of a busy service. When it comes to an industrial food processor, one material is king: stainless steel.

Stainless steel construction is non-negotiable. Its non-porous surface resists corrosion, prevents bacteria from finding a place to hide, and can handle the harsh chemicals used in daily sanitation. It's the gold standard for food safety and longevity.

Look for machines with a heavy, sealed base and stainless steel everything—bowls, blades, and housing. This isn't just about making the unit durable enough for a commercial setting; it also makes it much easier to clean and maintain, which is critical for meeting health codes.

Precision Tools and Attachments

A food processor is only as capable as its cutting tools. The real versatility of the machine is unlocked by the quality, variety, and design of its blades and discs. High-quality attachments are crafted from hardened stainless steel that holds a sharp edge longer, giving you clean, precise cuts that reduce bruising and food waste.

When you're checking out a processor, think about the range of attachments available and how they line up with your menu needs.

- S-Blades: The must-have for chopping, mixing, and puréeing in bowl processors.

- Slicing Discs: Look for adjustable models. Being able to control the thickness for things like cucumbers or potatoes is a game-changer.

- Shredding/Grating Discs: Different discs offer various shred sizes, perfect for everything from cheese and carrots to cabbage for slaw.

- Dicing Kits: If you do high-volume prep for things like salsa or mirepoix, a dicing kit will save you an incredible amount of time.

How quickly and safely you can swap out these parts is also a huge deal. A well-designed machine lets you change tools without a fight, keeping your prep line humming along. This practical, thoughtful engineering is what really separates the entry-level models from the true professional-grade food processors.

The Financial Case for a High-Quality Processor

It’s easy to look at an industrial food processor and see just a big-ticket expense. But that's missing the forest for the trees. A high-quality machine isn't a cost—it’s a strategic investment, one that’s engineered to pay you back in real, measurable ways across your entire operation.

Think of it as adding a turbocharger to your prep line. A single, powerful processor can knock out the work of several prep cooks in a fraction of the time, and it does it with perfect consistency every single time. This isn't about replacing your team; it's about freeing up your skilled staff from mind-numbing manual prep so they can focus on tasks that need a human touch—creativity, finesse, and plating.

Quantifying the Return on Investment

The ROI from a quality processor isn't some fuzzy, abstract concept. It shows up right on your P&L statement in three key areas: lower labor costs, less food waste, and better product quality. When you add these up, the financial argument for the investment becomes crystal clear.

For example, imagine dicing 100 pounds of onions. That could easily take a prep cook a few hours of tedious, tear-filled work, costing you real dollars in wages. An industrial food processor with a dicing blade can get the exact same job done in under 10 minutes. The labor savings from that one task alone, multiplied over a year, can be massive.

Slashing Labor and Boosting Efficiency

The most immediate and obvious win is the dramatic cut in labor hours you’ll spend on prep. By automating all that slicing, dicing, shredding, and puréeing, you take the most physically demanding and time-sucking tasks off your kitchen team's plate.

This efficiency boost sends a ripple effect through the whole kitchen.

- Reduced Labor Costs: It directly cuts down on the payroll hours needed for basic food prep, letting you run a leaner, more focused team.

- Increased Throughput: When prep is faster, you can produce more food in the same amount of time. This increases your kitchen's total capacity without needing to hire more people.

- Better Staff Allocation: Your skilled cooks can shift their focus to higher-value activities like finishing dishes, developing new recipes, or managing the line—all things that directly improve the guest experience.

This need for speed and efficiency is driving huge growth in the market. The global industrial food processing sector is expected to jump from USD 177.56 billion in 2025 to almost USD 318.29 billion by 2034, all because kitchens need to produce more, faster.

Enhancing Product Consistency and Brand Reputation

In the restaurant world, consistency is king. Customers come back because they want that same amazing experience they had last time. An industrial food processor is your secret weapon for making sure every single cut, slice, and purée is identical, from the first batch of the day to the last. This machine-level precision gets rid of human error and ensures your recipes are executed perfectly every single time.

This consistency has a direct financial payoff. It protects your brand by guaranteeing quality, which leads to fewer customer complaints, more glowing reviews, and a loyal customer base that trusts you to deliver.

A processor's precision isn't just an operational detail—it's a brand promise. Consistent texture in a sauce or uniform shreds on a salad communicates quality and reliability to your guests, which is a priceless asset for any foodservice business.

Minimizing Food Waste for a Healthier Bottom Line

Finally, an efficient processor helps you turn more of your raw ingredients into sellable food. The sharp, precise blades make clean cuts that minimize bruising and cell damage, which actually extends the shelf life of fresh produce. More importantly, it maximizes your yield, meaning less food ends up in the trash or compost bin.

When you can get more usable product out of every case of vegetables, you’re directly boosting your bottom line. Over a year, even a small reduction in food waste can add up to thousands of dollars in savings.

For those navigating the initial investment, our restaurant equipment financing guide offers practical solutions to make this essential upgrade more accessible. Beyond the initial purchase, the long-term financial case is also influenced by operational costs. Exploring how smart energy monitoring systems for food manufacturing can optimize these expenses is another way to protect your investment.

How to Choose the Right Processor for Your Business

Picking out an industrial food processor is way more than just flipping through a catalog. It’s a strategic move that has a real impact on your kitchen’s efficiency, the quality of your food, and ultimately, your bottom line. Get it right, and you create a smooth, seamless workflow. Get it wrong, and you’ve just introduced a frustrating bottleneck or an expensive machine that just gathers dust.

The best way to start isn’t by looking at spec sheets, but by taking a hard look at your own kitchen. By asking the right questions upfront, you can build a crystal-clear profile of the perfect machine for your unique operation. This approach guarantees you're investing in a true kitchen asset, not just another piece of hardware.

Start With Your Menu And Volume

First things first: look at what you actually cook. Your menu is the blueprint for your equipment needs. Are you famous for silky-smooth soups and purées, or are you churning out hundreds of pounds of sliced veggies for a massive salad bar every single day? The answer immediately points you toward very different types of processors.

Next, you need to get real about your numbers. "High volume" doesn't mean much without specifics.

- Daily Production Needs: Do the math. How many pounds of product do you need to process per hour or per day? This will steer you toward the right capacity.

- Batch vs. Continuous Work: Are you making big, single batches of sauce? A bowl cutter is your friend. Or do you need a non-stop flow of shredded cheese? That calls for a continuous feed model.

- Kitchen Footprint: How much physical space can you actually spare? Industrial food processors aren’t small, so measure your available area before you fall in love with a machine that won't fit.

Getting this initial analysis right is everything. A processor that’s too small will constantly hold up your prep line. One that’s too big is just a waste of capital and precious kitchen real estate. Our complete restaurant supply guide can help you figure out how new equipment fits into your overall kitchen layout.

Match Power and Capacity to Your Ingredients

Once you know your volume, it’s time to talk about capacity and power. For bowl models, capacity is usually measured in quarts or liters. For continuous feed units, it’s in pounds-per-hour. You’ll want a machine that can comfortably handle your busiest days with a little room to grow—running a smaller machine at 100% capacity all day is a surefire way to burn it out prematurely.

The motor's horsepower (HP) is just as critical. It’s what gives the processor its muscle to push through tough ingredients.

Think of it this way: a powerful motor is essential for dense, heavy ingredients like hard cheeses, root vegetables, or thick dough. Trying to process these with an underpowered machine will strain the motor, leading to overheating and costly repairs.

You also need to match the blade set to what you’re prepping. If you work with delicate herbs, you need razor-sharp blades that slice cleanly without bruising. For dense vegetables, you’ll need robust, durable discs that can handle constant, heavy use without getting dull too quickly.

Look Beyond the Price Tag

A lower upfront cost can be tempting, but it often hides long-term expenses down the road. The true value of an industrial food processor is found when you look at its total cost of ownership over its entire service life.

Think about these critical long-term factors:

- Warranty: A solid warranty is the manufacturer's vote of confidence in their own product.

- Service Support: When a machine goes down in the middle of a rush, how fast can you get a certified tech to your door?

- Parts Availability: Make sure replacement blades, bowls, and motor parts are easy to find and won't leave you waiting for weeks.

This kind of forward-thinking is becoming the norm as the industry evolves. The global food processing equipment market is projected to grow from USD 80.4 billion in 2025 to USD 106.2 billion by 2030, all driven by the demand for more efficient and reliable machines. You can learn more about these market forces and read the full research from the Food Production Solutions Association.

Essential Maintenance to Protect Your Investment

An industrial food processor is a serious investment, and just like the engine in a performance car, its lifespan and reliability come down to one thing: consistent care. Getting proactive with maintenance isn't just about keeping things clean. It’s a strategic move to head off expensive downtime, lock down food safety, and protect the very machine that makes your kitchen hum. Ignoring it is the fastest way to an unexpected breakdown right in the middle of a dinner rush.

Simply put, a well-maintained machine is a profitable one. A few simple, routine checks and cleaning habits will extend the life of your equipment, keeping it in peak condition for years. This is more than just wiping down the outside—it's about a disciplined approach to daily, weekly, and monthly tasks that keep your processor running like new.

Daily Cleaning and Sanitation Protocols

The most important maintenance happens every single day. At the end of each shift, the processor has to be completely broken down, cleaned, and sanitized. For preventing cross-contamination and bacterial growth, this is non-negotiable.

Start by disassembling all the removable parts—the bowl, blades, discs, lids, and pushers. Each component needs to be washed, rinsed, and sanitized according to health code standards. Pay close attention to the seals, gaskets, and any little crevices where food particles love to hide. A final wipe-down of the machine base with a food-safe sanitizer completes the daily reset. For a deeper dive into best practices, check out our comprehensive guide on cleaning restaurant equipment.

Weekly and Monthly Inspection Schedule

Beyond the daily scrub-down, a regular inspection schedule helps you spot small issues before they blow up into major problems. Spending a few minutes on this each week can save you from hours of downtime and some seriously expensive repair bills.

Weekly Checks:

- Blade and Disc Sharpness: Take a close look at all cutting edges. Dull blades don't just cut poorly—they bruise ingredients, which hurts your food quality and puts a ton of unnecessary strain on the motor.

- Seals and Gaskets: Check for any signs of cracking, brittleness, or wear and tear. A worn seal can cause leaks and quickly become a sanitation nightmare.

- Safety Interlocks: Test every single safety mechanism. You need to be sure the machine absolutely will not run if the bowl, lid, or pusher isn't locked in place correctly.

Monthly Checks:

- Lubrication: Pull out the manufacturer's guide and see if any moving parts need lubrication. Keeping them running smoothly prevents premature wear.

- Power Cords and Connections: Inspect the power cord for any fraying or damage. This is a critical step for electrical safety and reliable operation.

Think of maintenance as the official owner's manual for long-term reliability. Every task, from sharpening a blade to testing a safety switch, is a preventative measure that maximizes performance and ensures your processor remains a productive, safe, and valuable part of your kitchen workflow. This consistent attention to detail is what truly protects your investment.

Got Questions? We’ve Got Answers.

When you’re trying to pin down the right specs for an industrial food processor, a few practical questions always come up. Here are some straightforward answers to the things kitchen managers and chefs ask us the most.

What’s the Difference Between a Batch Bowl and a Continuous Feed Processor?

Think of it this way: a batch bowl processor is like the supercharged, heavy-duty cousin of the one you might have at home. It’s a self-contained unit perfect for making specific amounts of sauces, dips, pâtés, or any kind of emulsion where everything gets mixed together in one sealed container.

A continuous feed processor, on the other hand, is built for non-stop, high-volume prep work. You feed ingredients into a chute while it’s running, and the machine spits out the sliced, diced, or shredded product from another opening. It's the go-to for shredding mountains of cheese for pizza night or slicing an endless supply of cucumbers for a salad bar.

How Do I Know What Motor Size I Need?

This all comes down to your menu and how much you produce every day. If you’re mostly working with softer ingredients for lighter tasks—think tomatoes, herbs, or leafy greens—a 1 to 2 horsepower (HP) motor will probably get the job done.

But if you’re planning on heavy-duty, daily use with dense foods like hard cheeses, root vegetables, or even dough, you absolutely need a motor that's 3 HP or higher. Trying to save a few bucks on a smaller motor is a mistake. It will struggle, overheat, and burn out on you, so it's always smarter to invest in more power than you think you need.

Pro Tip: An underpowered motor isn't just slow; it's a liability waiting to happen. Overworking it leads to expensive repairs and unexpected downtime right in the middle of a dinner rush. Always err on the side of more horsepower.

Are Blades and Attachments Interchangeable Between Brands?

Almost never. Attachments like blades and discs are engineered with incredible precision to fit specific models from a single brand. Trying to force a part from a different manufacturer onto your machine isn't just a bad idea—it's extremely dangerous.

An improper fit can wreck the motor, shatter the attachment, or cause serious injury to whoever is using it. To keep everyone safe and your machine running properly, always buy certified replacement parts for your specific industrial food processor model directly from the manufacturer or an authorized dealer.

Ready to find the perfect workhorse for your kitchen? Explore a wide range of top-tier industrial food processors at The Restaurant Warehouse and get your operation equipped for maximum efficiency. Visit our online store to get started.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment