Holy Smokes! Top Commercial Smoker Ovens Reviewed

The Rise of Commercial Smoker Ovens in Modern Restaurants

A commercial smoker oven is a specialized cooking appliance designed for restaurants and foodservice operations that want to offer smoked meats and other foods with authentic barbecue flavor. These units combine the smoking capabilities of traditional pit smokers with the precision and convenience of commercial ovens.

What is a commercial smoker oven? - An indoor cooking appliance that smokes and cooks food at controlled low temperatures - Operates between 125-550°F depending on the model - Uses wood chips, electricity, or gas for heat and smoke generation - Features insulated construction for energy efficiency - Includes programmable controls for consistent results

Recent studies show the popularity of smoked meat is increasing by a remarkable 300% per year on average, driving restaurants to add authentic barbecue items to their menus regardless of their primary cuisine.

"Nothing pleases a crowd quite like barbecue," notes one industry expert, explaining why so many establishments are investing in commercial smoker technology.

Commercial smoker ovens solve several critical challenges for restaurants. They operate at lower temperatures than standard ovens, which helps reduce meat shrinkage and allows for more portions per cut. Models like Alto-Shaam's units with Halo Heat technology minimize protein shrinkage, helping meat retain its natural juiciness and tenderness for higher yields.

The economics make sense too. The average operating cost for a 12-hour cook in a Cookshack SM260 commercial smoker oven is just $1.94, while producing up to 240 pounds of pork butt, 200 pounds of brisket, or 40 whole chickens per load.

For restaurant owners looking to expand their menu offerings without adding specialized staff, commercial smoker ovens offer a "set it and forget it" solution. Many models include cook-and-hold functions that automatically transition to warming mode after cooking is complete, freeing staff for other tasks.

How a Commercial Smoker Oven Works

Ever wondered how restaurants serve up that melt-in-your-mouth brisket with the perfect smoke ring? The secret lies in their commercial smoker oven - a remarkable piece of kitchen equipment that takes the guesswork out of smoking meats.

Unlike traditional smokers that demand constant babysitting, these professional units deliver consistent, mouthwatering results every single time. They operate on a beautifully simple principle: gentle, low-temperature cooking combined with just the right amount of smoke exposure.

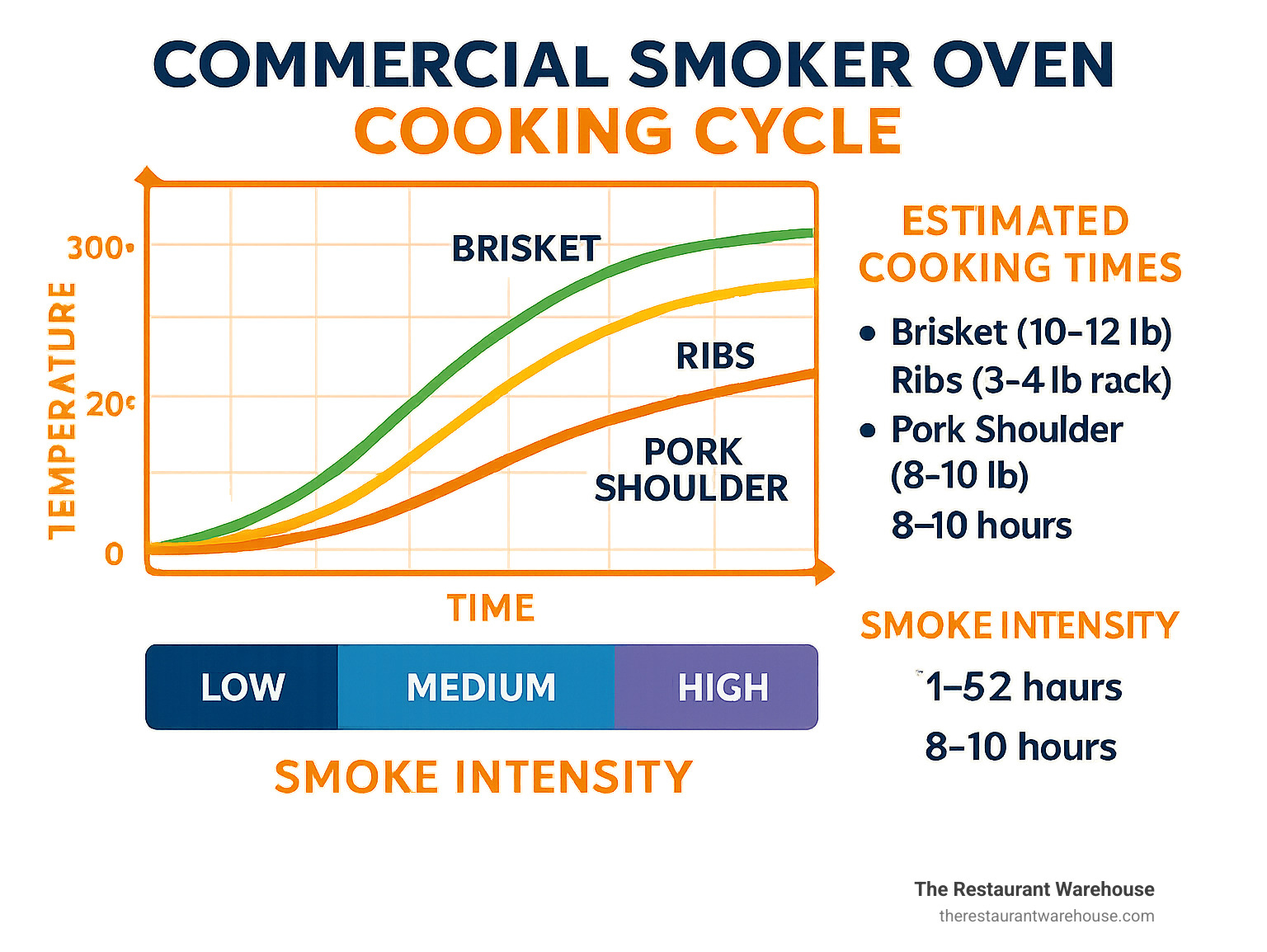

Most commercial smoker ovens maintain temperatures between 125°F and 300°F - significantly lower than standard ovens. This "low and slow" approach gives proteins plenty of time to break down, creating that fork-tender texture we all crave in great barbecue. The magic happens when tough collagen transforms into silky gelatin, something that only happens with patience!

What truly sets these units apart is their precision. Gone are the temperature swings and uneven cooking that plague outdoor smokers. Whether it's raining, snowing, or blazing hot outside, your indoor commercial smoker oven delivers the same delicious results day after day.

Heat & Smoke Generation in a Commercial Smoker Oven

The heart of any smoker is how it creates heat and that mouthwatering smoke. Different models approach this in various ways:

Electric elements provide consistent, worry-free heat without the hassle of managing fuel. Just set it and forget it! Gas burners, powered by natural gas or propane, offer faster heating and typically reach higher maximum temperatures - perfect when you need a bit more versatility.

The flavor magic happens in the wood chip box, where hardwood chips or chunks slowly smolder rather than burn. This creates that distinctive smoke that infuses your food with authentic barbecue flavor. Many chefs swear by different wood varieties - hickory for robust flavor, apple for sweetness, or mesquite for that Southwestern kick.

Most models include clever drip shields that catch meat drippings. When these juices hit the hot surface, they vaporize, creating additional flavorful smoke and moisture. It's like getting a flavor bonus from what would otherwise go to waste!

Water pans serve double duty by maintaining humidity (keeping your meats juicy) while catching drippings to prevent flare-ups. The carefully designed airflow ensures that heat and smoke circulate evenly, giving you consistent results from the edges to the center of your cooking chamber.

Cook-and-Hold Function in a Commercial Smoker Oven

The real game-changer in modern commercial smoker ovens is the cook-and-hold function. This smart feature essentially turns your smoker into an overnight cooking assistant that never calls in sick!

Here's the beauty of it: you set your desired cooking temperature and target internal food temperature, then let the internal probes do the monitoring. When your meat reaches perfection, the oven automatically switches to holding mode (typically around 140°F) where food stays safe and delicious for hours without overcooking.

This clever automation transforms your restaurant operations in several ways. You can load the smoker before closing and return to perfectly smoked meats in the morning - talk about making money while you sleep! The labor savings are substantial since no one needs to hover around checking temperatures or making adjustments.

Your food quality improves too. The precise temperature control minimizes moisture loss, which means higher yields and more portions from each cut of meat. Every batch comes out with consistent texture, moisture, and doneness - something your customers will definitely notice and appreciate.

As Chef Rick Palesh puts it, "We were looking for an electric smoker oven as it minimizes labor... duplicating the setup becomes really hard with traditional methods." In today's challenging labor market, having equipment that reduces staffing needs while improving quality is nothing short of revolutionary.

More info about kitchen equipment

Picking the Perfect Model & Fuel Type

Choosing the right commercial smoker oven feels a bit like finding your soulmate in the kitchen - it needs to match your space, budget, and cooking style perfectly. Let's break down your options to help you make a choice you'll be happy with for years to come.

When restaurant owners ask me about smoker ovens, I always start by asking about their menu plans. Will you be smoking 20 racks of ribs daily or just adding a few signature items? Your answer determines whether you need a compact countertop unit or a floor model that can handle hundreds of pounds at once.

Electric Smoker Ovens

Electric models have become the darlings of indoor commercial kitchens, and for good reason.

These user-friendly units offer true plug-and-play convenience - most standard models connect to a regular outlet, though the hungry beasts that handle larger loads might require 220V power. What chefs love most is the set-it-and-forget-it precision. Digital thermostats maintain exact temperatures without the constant babysitting traditional smokers demand.

From a practical standpoint, the numbers make sense too. Running an electric commercial smoker oven for a full 12-hour smoking session typically costs less than a cup of coffee - under $2 in electricity. And because there's no open flame, your ventilation requirements stay simpler (though you'll still need that hood system in most jurisdictions).

The SmokinTex 1500-CXLD showcases what these units can do, handling up to 30 whole chickens, 500 wings, or 36 racks of baby backs in one go - perfect for restaurants where consistency matters more than smokemaster credentials.

Gas-Fired Units

For the heat-seekers among us, gas smoker ovens bring serious firepower to your kitchen lineup.

Gas units deliver impressive BTU output - Town's Chinese smokehouses pump out between 45,000 and 75,000 BTU, creating that beautiful, robust bark on briskets that many BBQ aficionados crave. When you're opening and closing doors during service, that faster temperature recovery becomes invaluable.

Many chefs with traditional BBQ backgrounds prefer gas units because the flavor profile more closely mimics old-school smoking techniques. Plus, during those inevitable power outages, you'll still be serving while others are turning customers away (though note that igniters may still need electricity).

Town Food's commercial Chinese smokehouses exemplify this category beautifully, with their largest 36-inch model handling up to 175 pounds of ribs or 24 whole chickens per load - perfect for high-volume operations.

Wood & Hybrid Designs

For purists seeking that authentic smokehouse experience, wood-burning and hybrid units deliver undeniable authenticity.

Nothing creates that coveted pink smoke ring like actual wood combustion. Your marketing team will love the menu appeal of "wood-fired" items too - customers consistently pay premium prices for that authentic approach. Modern hybrid units offer the best of both worlds, using electricity or gas for consistent heat while wood provides the flavor.

These units shine in BBQ-focused restaurants where authenticity is your calling card, though you'll need proper ventilation systems to handle the additional smoke output.

Beyond fuel type, consider these practical specs before making your final decision:

Your capacity needs might range from countertop models handling 30-40 pounds to floor giants accommodating 240+ pounds of product. Temperature flexibility matters too - most units operate between 125-550°F, but verify the range meets your menu requirements.

Don't overlook insulation thickness - better insulation means energy savings and cooler external surfaces (your staff will thank you). Control systems range from simple analog dials to sophisticated digital interfaces with remote monitoring capabilities that send alerts to your phone.

Finally, check what accessories come standard versus optional. Those extra racks, probes, and chip boxes can add up quickly if purchased separately.

How To Use your Wood Fired Oven as a Smoker

Why Invest in a Commercial Smoker Oven

Let's face it – adding a commercial smoker oven to your kitchen isn't a small decision. But talk to restaurant owners who've made the leap, and you'll hear the same thing: the returns can be absolutely game-changing for your business. Here's the real story on why more restaurants are bringing the smoke indoors:

Profit & ROI Snapshot

The numbers behind commercial smoker ovens tell a compelling story that any restaurant owner can appreciate:

When you cook meats traditionally, you're watching 15-20% of your protein (and profit) literally evaporate through shrinkage. Commercial smoker ovens cut this dramatically – keeping shrinkage under 8% through their gentle, moisture-preserving magic.

Think about what this means in real terms: If your restaurant smokes 100 pounds of brisket each week, you're suddenly serving 7-12 more portions from the exact same product. That's money that was literally going up in smoke before.

Customers are also happy to pay premium prices for authentic smoked flavors. There's something about "house-smoked" on a menu that justifies a higher price point in the customer's mind – and in your bank account.

The efficiency of these units is almost hard to believe. Models like the Cookshack use just 1 ounce of wood to smoke 60 pounds of product. Let that sink in – that's practically nothing compared to traditional smoking methods. The average operating cost for a full 12-hour cook comes in at just $1.94, making it one of the most economical cooking methods per pound of finished product you can find.

Most restaurant owners report their commercial smoker oven pays for itself in just 8-14 months based solely on food cost savings and increased yield. And that's not even counting the additional revenue from expanded menu offerings!

Labor & Energy Efficiency Wins

In today's challenging labor market, the operational advantages of a commercial smoker oven might be even more valuable than the food cost savings:

The overnight cooking capability transforms your kitchen's productivity. Load the smoker before closing, set the program, and return to perfectly cooked briskets, pork shoulders, and ribs in the morning. You're essentially adding production hours without adding a single minute of labor costs.

"We were looking to add authentic barbecue to our menu but couldn't justify a dedicated pitmaster position," one restaurant owner told us. "Our commercial smoker oven let us expand our offerings without expanding our staff."

The "set it and forget it" functionality eliminates the babysitting required by traditional smoking methods. No more checking temperatures, adjusting vents, or adding fuel every hour. Your team can focus on other tasks while the smoker quietly works its magic.

Technologies like Alto-Shaam's Halo Heat provide gentle, radiant warmth that uses significantly less energy than conventional cooking methods. Your utility bills will thank you.

For tech-savvy operators, advanced models include ChefLinc or similar systems that allow you to monitor cooking progress from your smartphone. Imagine getting alerts when your brisket hits the perfect temperature, or adjusting settings remotely when needed.

Perhaps best of all, indoor commercial smoker ovens enable consistent barbecue production year-round. Rain, snow, extreme heat – none of it matters anymore. Your smoked specialties can be a menu staple in any season.

More info about convection ovens

Installation, Safety & Upkeep Essentials

Getting your commercial smoker oven properly set up and maintained isn't just about following rules—it's about creating a safe, efficient kitchen where you can smoke delicious food for years to come. Let's walk through what you need to know to keep things running smoothly.

Installation Requirements

When it comes to installing your smoker oven, there's a bit more involved than just finding a spot and plugging it in.

Your commercial smoker oven will likely need to live under a Type I hood with fire suppression. This is true even for electric models, since they still produce smoke and food particles that need to be vented. Think of your hood system as your smoker's best friend—it keeps the air clean and prevents your entire restaurant from smelling like a smokehouse (unless that's what you're going for!).

Good ventilation is absolutely essential. Nobody wants smoke drifting into the dining room or neighboring businesses. Your local codes will specify exactly what's required, but don't try to cut corners here—proper ventilation protects your staff, customers, and equipment.

Depending on which model you choose, you'll need the right utility connections. Electric models might need 120V or 220V power, gas models require properly sized gas lines, and all units benefit from having water access nearby for cleaning. And don't forget about clearances—most units need 6-12 inches of space on all sides to prevent fire hazards.

Those big floor models can weigh upwards of 500 pounds when loaded with delicious briskets and ribs, so make sure your floor can handle the weight. The last thing you want is your smoker taking an unexpected trip to the basement!

Always check with your local Authority Having Jurisdiction (AHJ) before installation. Building codes vary widely, and what works in Texas might not fly in New York.

Cleaning a Commercial Smoker Oven

A clean smoker is a happy smoker, and your food will taste better too. Developing a regular cleaning routine will extend your equipment's life and keep health inspectors smiling.

Daily cleaning doesn't have to be a chore if you stay on top of it. After each smoking session, empty and clean that drip pan—it's full of rendered fat that can become a fire hazard if left to build up. Take out the racks and give them a good scrub, and wipe down the interior to remove food particles. Don't forget to empty the ash and wood chip residue from your smoke box—tomorrow's smoke flavor should come from fresh wood, not yesterday's ash.

On a weekly basis, give your smoker a deeper clean with non-toxic, food-safe cleaners. Pay special attention to those door gaskets—they need to seal properly for your smoker to maintain temperature. Check your ventilation components too, as grease and smoke residue can build up quickly.

Once a month, tackle the bigger maintenance tasks. Descale water pans and humidity systems with a vinegar solution to prevent mineral buildup. Clean the exterior surfaces, focusing on control panels and handles that get touched frequently. Inspect burners or heating elements for any signs of wear or buildup, and make sure smoke vents and chimney components are clear.

Most manufacturers recommend using gentle, food-safe cleaners like vinegar or citrus-based solutions for the interior. For those shiny stainless steel exteriors, always clean with the grain to keep them looking their best. Your smoker will thank you with years of faithful service and consistently delicious food.

Certifications & Compliance

When shopping for your commercial smoker oven, certifications aren't just fancy stickers—they're your assurance that the equipment meets important safety standards.

Look for the NSF mark, which tells you the equipment meets food safety standards set by the National Sanitation Foundation. ETL or UL listings verify electrical safety compliance, while ANSI certification confirms adherence to industry standards. If you're going with a gas-powered unit, the AGA mark verifies it meets gas safety standards. And for meat processing facilities, USDA approval is particularly important.

These certifications matter to more than just you—they're often required by local health departments, insurance providers, building inspectors, and fire marshals. Having properly certified equipment can prevent headaches during inspections and might even affect your insurance rates.

Compliance isn't a one-time thing. Following manufacturer guidelines for installation, operation, and maintenance keeps your equipment in compliance throughout its lifecycle. Many jurisdictions require annual inspections of commercial kitchen equipment, especially ventilation systems, so keep your maintenance records handy.

Taking care of these essentials from day one will ensure your commercial smoker oven remains a safe, efficient, and profitable addition to your kitchen for years to come.

Roundup: Best-in-Class Smoker Oven Categories

Let's face it—choosing the right commercial smoker oven feels a bit like picking the perfect car. You need something that fits your space, meets your production needs, and doesn't break the bank. At The Restaurant Warehouse, we've curated options for every kitchen, from the busy BBQ joint to the corner café looking to spice up their menu.

High-Capacity Electric Workhorse

When volume is the name of the game, our large-capacity electric smokers are the unsung heroes of commercial kitchens everywhere. These floor models are the workhorses that keep on giving.

Think of them as your overnight kitchen staff that never calls in sick. With capacity for up to 240 pounds of product per load and over 3,400 square inches of cooking space, these gentle giants transform tough cuts into melt-in-your-mouth masterpieces while you sleep.

What I love most about these units is their "set it and forget it" functionality. Load them up with briskets before closing, program your cooking cycle, and return to perfectly smoked meat in the morning—no 3 AM alarm necessary. The digital controls and multiple temperature probes ensure consistent results every time, even when different staff members are operating the equipment.

Best for: Those serious BBQ restaurants where people line up before opening, catering operations juggling multiple events, and foodservice operations that need to feed an army.

Compact Countertop Hero

Not every kitchen has room for another floor-standing appliance—we get it! That's where our compact countertop models shine. These space-saving wonders pack impressive smoking power into a footprint that fits comfortably under standard counters.

Despite their smaller stature, these units can handle up to 30 whole chickens per load. Plus, they plug into standard 120V outlets, so you won't need to call an electrician before installation. Many of our restaurant clients start with these models to test smoked items on their menu before investing in larger units.

The mobility factor is another huge plus—roll it out for weekend service and tuck it away when not needed. It's like having a BBQ pit that doesn't demand its own zip code.

Best for: Cozy neighborhood spots, food trucks with precious square inches to spare, and restaurants dipping their toes into the smoky waters of BBQ menu additions.

Vertical Chinese-Style Smokehouse

There's something almost magical about watching ducks and ribs hanging in a vertical smoker, slowly changing into lacquered, smoky perfection. Our Chinese-style smokehouses bring this traditional technique into modern kitchens.

With specialized hanging hooks and powerful burners pumping out up to 75,000 BTU, these units create that perfect balance of smoke, moisture, and heat needed for authentic char siu and Peking duck. The dual water-pan system maintains ideal humidity levels, preventing your precious proteins from drying out during the long smoking process.

What makes these units particularly special is how they blend traditional Asian smoking techniques with temperature ranges (175-550°F) versatile enough for Western-style roasting. It's truly the best of both worlds.

Best for: Asian fusion restaurants, specialty BBQ shops looking to expand their offerings, and chefs who appreciate the dramatic presentation of hanging smoked meats.

Multi-Use Cook-and-Hold Smoker

If your kitchen philosophy is "why have three appliances when one will do?", our multi-function smokers will be your new best friend. These Swiss Army knives of the smoking world can smoke, roast, and hold—sometimes all in the same cooking cycle.

The magic happens with their programmable multi-stage cooking capabilities. Start with a smoke cycle, transition to roasting, then automatically hold at serving temperature until you're ready. The probe-driven temperature control takes the guesswork out of cooking, ensuring perfect doneness every time.

Many models feature technologies like Alto-Shaam's gentle Halo Heat, which surrounds food with consistent temperature without harsh air currents that dry out your product. The result? Less shrinkage, more yield, and more profit on your bottom line.

Remote monitoring capabilities mean you can check on your overnight brisket from home—peace of mind without the middle-of-the-night kitchen visit.

Best for: Full-service restaurants balancing diverse menu needs, hotels serving everything from breakfast to banquets, and operations where precision and consistency are non-negotiable.

Modular Flow-Through System

When you're operating at industrial scale, our modular smoking systems are the ultimate solution. These aren't just smokers—they're production lines for perfectly smoked products.

With configurations ranging from 4 to 30 trucks and capacity up to a staggering 4,800 pounds, these systems can meet massive production demands while maintaining quality. The reversing airflow technology ensures even cooking throughout the chamber, eliminating the hot spots that plague lesser units.

Choose between vertical or horizontal airflow based on your specific products, and select batch, flow-through, or indexed travel designs to match your production style. These systems represent smoking technology at its most advanced—commercial smoking with scientific precision.

Best for: Food manufacturers who measure production in tons rather than pounds, large-scale catering operations serving thousands, and meat processing facilities where consistency is everything.

At The Restaurant Warehouse, we pride ourselves on offering these commercial smoker oven solutions at genuine wholesale prices. We skip the high commissions and retail overhead, passing those savings directly to you. Because we believe great BBQ shouldn't come with a side of sticker shock.

More info about restaurant kitchen layout

Frequently Asked Questions about Commercial Smoker Ovens

What foods can I smoke besides meat?

When most people think of a commercial smoker oven, they immediately picture racks of ribs or slow-cooked brisket. But these versatile workhorses can do so much more! Your smoker can transform an impressive variety of ingredients into menu standouts.

Vegetables take on magical qualities when kissed by smoke. Bell peppers develop a sweet, charred complexity, while mushrooms become meaty flavor bombs. Root vegetables like carrots and beets? They're absolutely transformed at 225-250°F, developing a caramelized sweetness that balances perfectly with the smoky notes.

Ever tried smoked cheese? It's a game-changer for charcuterie boards and specialty sandwiches. With a cold smoking attachment (keeping temperatures below 90°F), hard cheeses like cheddar, gouda, and provolone develop complex flavors without melting. Your customers will definitely notice the difference between store-bought smoked gouda and your house-made version!

Nuts and seeds become addictive bar snacks when given the smoke treatment. Imagine offering house-smoked almonds or pecans as a signature item that guests can't get anywhere else. The same goes for spices and salt – smoked paprika made in-house adds depth to countless dishes.

For innovative dessert components or craft cocktail ingredients, try smoking fruits like apples, pears or even citrus. And don't overlook oils – cold-smoked olive oil makes an incredible finishing touch that lifts simple dishes to memorable status.

The secret is adjusting your approach based on what you're smoking. Delicate items need gentler treatment than tough cuts of meat, but your commercial smoker oven can handle it all with the right settings.

Can one unit handle both hot and cold smoking?

"Can I do both hot and cold smoking without buying two separate units?" It's one of the most common questions we hear, and I'm happy to say the answer is often yes!

Many modern commercial smoker ovens are designed to handle both hot smoking (cooking with smoke at 165-300°F) and cold smoking (adding smoke flavor below 90°F without cooking). This versatility means one piece of equipment can produce everything from traditional BBQ to delicate cold-smoked salmon.

When shopping for a dual-purpose unit, look for these features:

Cold smoke plates or attachments generate smoke without significant heat – perfect for delicate items like cheese or salmon. The SmokinTex 1500-CXLD, for example, offers optional cold smoke plates specifically designed for this purpose.

The best units can maintain temperatures as low as 60-70°F for true cold smoking. Some models even allow smoke to be generated externally and piped into the chamber, keeping temperatures at the absolute minimum.

Not every commercial smoker oven has these capabilities though, so if cold smoking is important for your menu concept, double-check that your chosen model can maintain those necessary low temperatures. Your menu versatility will thank you!

How often should the wood chip box be refilled?

Ah, the wood chip question! The answer depends on several factors, but I'll give you the practical insights that will save you from hovering anxiously over your commercial smoker oven.

Think of wood chips as a seasoning – you want enough to flavor your food properly, but not so much that it overwhelms. Most of the smoke absorption happens in the first few hours of cooking, so extended smoking beyond this point adds minimal additional flavor.

For specific guidelines, here's what we typically see: - Small units (SM-24): Wood chip boxes typically need refilling about every 30 minutes - Medium units (SM-30): You'll get approximately 45 minutes per load - Large units (SM-36): These can go up to 90 minutes between refills

Many professional chefs follow a simple approach that works beautifully: Start with a full box of chips for the first hour, refill halfway through the cook for a second round of smoke, then allow the final portion of cooking to proceed without additional smoke. This prevents over-smoking while ensuring proper flavor development.

Your cooking temperature makes a difference too – higher temperatures burn through wood chips faster. And different woods have different burn rates; hickory tends to last longer than lighter fruitwoods.

If the thought of regular refilling makes you wince, look for models with automatic wood chip feeders. These clever devices eliminate the need for manual replenishment during cooking cycles – perfect for overnight cooks when you'd rather be sleeping than adding more wood chips at 3 a.m.!

Conclusion

The rise of commercial smoker ovens represents a game-changing evolution in restaurant equipment. These remarkable units have transformed what was once a weather-dependent, labor-intensive process into something any restaurant can master year-round. The benefits speak for themselves:

When you invest in a commercial smoker oven, you're not just buying equipment – you're open uping a whole new dimension of flavor and efficiency. The reduced shrinkage means you'll get more portions from every cut of meat, turning what might have been 15-20% loss into less than 8%. That's money staying in your pocket with every brisket, pork shoulder, or rack of ribs.

The labor savings are just as impressive. Remember those long nights of constantly checking temperatures and adjusting airflow on traditional smokers? Those days are gone. With automated cook-and-hold functionality, you can literally load your smoker before closing, set the program, and walk into perfectly finished product the next morning. Your staff can focus on other tasks while the smoker works its magic overnight.

Weather worries? Not anymore. While outdoor pit masters are at the mercy of rain, wind, and seasonal changes, your commercial smoker oven keeps producing consistent results indoors, 365 days a year. That consistency translates directly to customer satisfaction and repeat business.

In today's competitive restaurant landscape, menu differentiation is everything. The authentic smoke flavor these units produce gives you a distinctive selling point that attracts customers and justifies premium pricing. When diners see "house-smoked" on your menu, they know they're in for something special.

And let's talk efficiency – modern commercial smoker ovens are remarkably economical to operate. When you can smoke 240 pounds of meat for less than $2 in electricity, the math becomes pretty compelling. Many of our customers report complete ROI in under a year just from food cost savings alone.

At The Restaurant Warehouse, we understand that finding the right equipment at the right price is essential to your success. That's why we offer these incredible units at wholesale prices – no inflated markups, no high commissions, just honest value passed directly to you. Our team is passionate about helping you find the perfect smoker for your specific operation, whether you're a dedicated BBQ joint or a fine dining establishment looking to expand your flavor palette.

The smoked food trend continues its impressive 300% annual growth, and there's never been a better time to position your restaurant to capitalize on this demand. Your customers are craving these flavors – why not give them what they want while boosting your bottom line?

Ready to transform your menu and operations with a commercial smoker oven? We're here to help with personalized recommendations based on your unique needs and budget. Let's make some magic happen in your kitchen.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment