From Home Baker to Pro: Finding Your Perfect Commercial Stand Mixer

Why Choosing the Right Industrial Stand Mixer Matters for Your Growing Business

Selecting an industrial stand mixer comes down to three critical factors: capacity (measured in quarts), motor power (measured in horsepower), and mixer type (planetary for versatility or spiral for dough specialization). Most small to mid-sized operations thrive with a 20-30 quart planetary mixer featuring a 1.5-2 HP motor, while high-volume bread or pizza operations benefit from dedicated spiral mixers. Prices range from $800 for basic 10-quart models to over $30,000 for large-scale floor units.

Quick Comparison:

| Mixer Type | Best For | Typical Capacity | Price Range |

|---|---|---|---|

| Planetary | Bakeries, restaurants, varied menus | 10-80 qt | $800-$15,000 |

| Spiral | Pizzerias, artisan bread bakeries | 30-175 lbs dough | $3,000-$30,000+ |

The global market for industrial mixers is growing, with the food and beverage industry driving most of the demand. The reason is simple: professional kitchens can't scale without reliable mixing equipment. Planetary mixers are particularly popular due to their incredible versatility.

Whether you're outgrowing a home mixer or opening your first professional kitchen, the jump from domestic to professional-grade equipment represents a fundamental shift in capability. A home mixer might handle a few batches per week, but an industrial stand mixer is engineered for continuous daily operation, handling demands that would destroy a residential unit in weeks.

The challenge isn't just finding a mixer; it's finding the right mixer for your specific operation, budget, and growth trajectory. A 10-quart countertop model may limit your production within six months, while a 60-quart floor mixer could sit underused if your volume doesn't justify the cost. Getting this decision wrong means either replacing equipment prematurely or watching profits shrink as you hand-mix batches that should be automated.

Why Your Business Needs a Professional-Grade Stand Mixer

Every growing food business reaches a point where its equipment can no longer keep up with its success. Whether you've landed a major wholesale account or your weekend market stall has a permanent line, you realize the tools that got you here won't get you where you're going. An industrial stand mixer isn't just a larger version of a home appliance; it fundamentally changes what your business can accomplish. It's the difference between mixing five batches of cookie dough in an afternoon versus twenty batches in the same time, with better consistency and less physical strain.

The Limits of Domestic Mixers

Many entrepreneurs describe the moment their home mixer finally gave out, usually with a burning smell or a grinding noise mid-batch. Domestic mixers are designed for occasional baking, not rigorous production schedules. They are typically built with smaller motors (often under 1 HP) and plastic gears that cannot handle the torque required for dense doughs. This leads to several predictable failures in a professional setting:

- Motor Burnout: Extended use or heavy loads cause the motor to overheat and eventually fail.

- Small Batch Sizes: A 5 to 7-quart bowl is impossibly limiting for volume production, forcing you to make numerous small batches, which wastes time and increases the chance of inconsistency.

- Inconsistent Mixing: Underpowered motors struggle to properly incorporate ingredients, leaving streaks of unmixed flour or butter.

- Gear Wear: Plastic gears strip and wear out quickly under heavy use, leading to costly repairs or replacement.

- Inability to Handle Dense Doughs: Stiff doughs for bread, pizza, or bagels place extreme stress on a domestic mixer's components, leading to rapid failure.

The Professional Advantage: Built for Business

Upgrading to an industrial stand mixer is like switching from a sedan to a cargo van for a delivery business. It’s a tool specifically designed for the job.

- Continuous Operation: These mixers feature powerful motors (1.5 HP is standard for 20-quart models) and all-metal, gear-driven transmissions. They can run for hours without overheating, eliminating production bottlenecks.

- High-Volume Capacity: A 20-quart mixer handles dozens of loaves in a single batch, while a 60-quart floor model can produce enough cookie dough for a week of sales. Fewer batches mean less labor and more consistent results.

- Superior Power: The motor and transmission work together to knead even the stiffest, low-hydration doughs without straining. What would destroy a home mixer is routine work for a professional-grade machine.

- Long-Term Reliability: Built with stainless steel components and durable gears, these mixers are designed for years of daily use, resulting in a lower total cost of ownership.

- Improved Safety & Certification: Features like bowl guards, safety interlocks, and overload protection are standard. They also carry certifications like NSF and ETL, which are often required by health inspectors. NSF certification confirms the mixer meets public health and safety standards established by organizations like NSF International.

Planetary vs. Spiral Mixers: Choosing the Right Action for Your Recipe

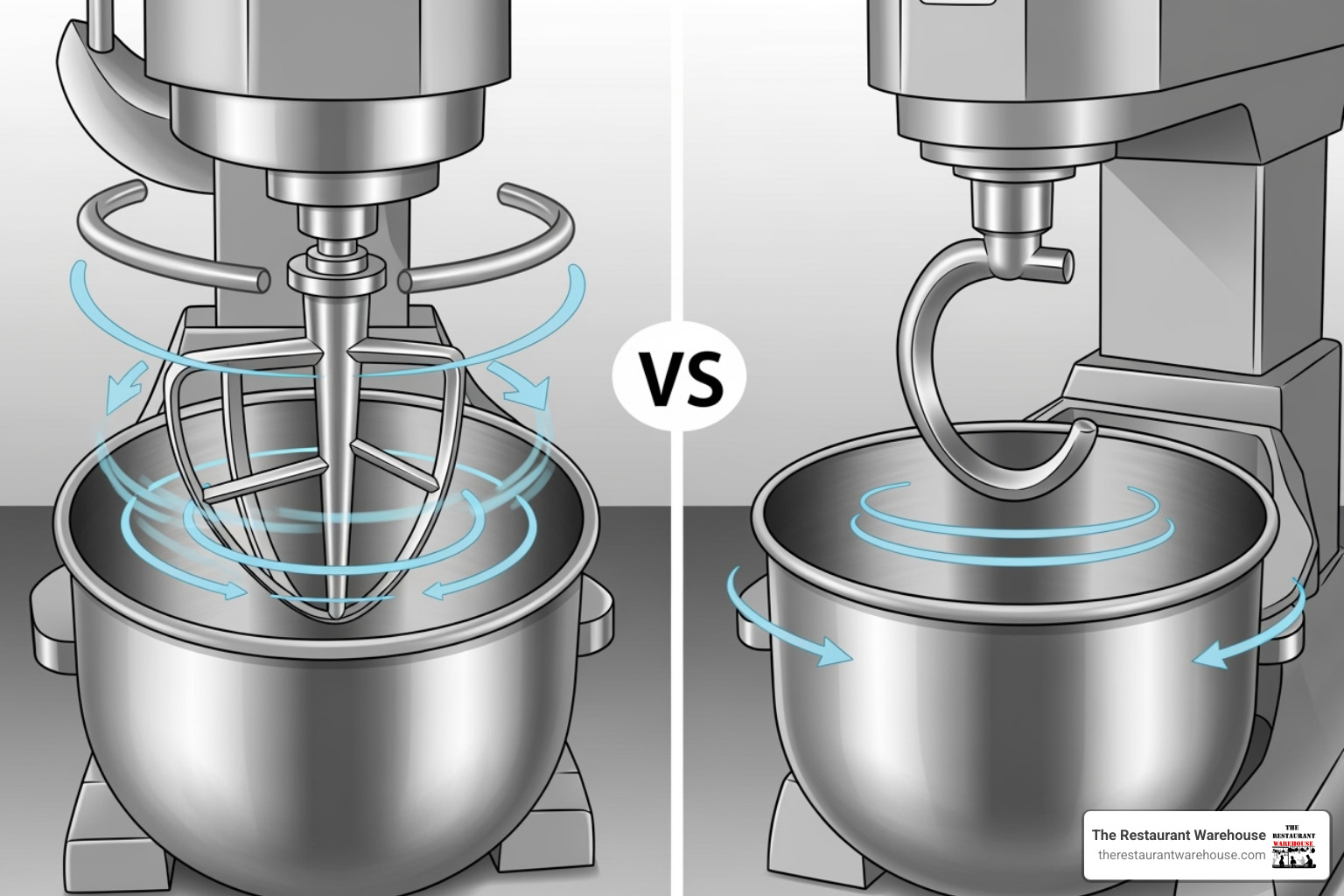

When shopping for an industrial stand mixer, one of the biggest decisions is choosing between a planetary and a spiral mixer. They both mix ingredients, but their mechanics and ideal applications are vastly different. Understanding this distinction is key to avoiding an expensive mistake.

Planetary mixers are the versatile go-to choice for most professional kitchens, but that doesn't mean they're right for everyone. If you run a pizzeria or artisan bakery where dough is the star, a spiral mixer might be the better investment.

The fundamental difference is in their movement. A planetary mixer has an attachment that spins on its own axis while also orbiting the bowl, much like a planet orbiting the sun. This dual action ensures every part of the bowl is reached, making it perfect for thoroughly mixing a wide variety of ingredients.

A spiral mixer takes a different approach. The bowl itself rotates while a stationary, spiral-shaped hook kneads the dough. This gentle, low-friction action is brilliant for developing gluten structure without overworking or overheating the dough, resulting in a superior texture and rise.

Think of a planetary mixer as a multi-tool, handling many jobs well. A spiral mixer is a specialized instrument, mastering one task exceptionally. Your choice depends entirely on your menu.

The All-Purpose Powerhouse: The Planetary Mixer

If your menu includes cakes, cookies, batters, frostings, and sauces, you need a planetary industrial stand mixer. This is the workhorse that adapts to any task. The magic is in its interchangeable attachments:

- A wire whip for aerating ingredients like cream and egg whites.

- A flat beater for mixing cake batters, cookie dough, and creaming butter and sugar.

- A dough hook for kneading medium-consistency doughs.

This adaptability makes planetary mixers the backbone of diverse operations like neighborhood bakeries, restaurant prep kitchens, and catering companies. The planetary action scrapes the sides and bottom of the bowl, ensuring all ingredients are fully incorporated without constant stopping and scraping. If you need one machine to do it all, this is your answer.

The Dough Specialist: The Spiral Mixer

If your business lives and breathes dough—making hundreds of pizzas a day or baking artisan loaves—a spiral industrial stand mixer is worth every penny. It is a master of one craft: dough.

The stationary spiral hook and rotating bowl mimic gentle hand-kneading, developing gluten without generating excess heat. This is crucial for preventing tough, dense dough and preserving yeast activity. For high-hydration doughs like ciabatta or Neapolitan pizza, this gentle handling makes all the difference.

Spiral mixers also offer a significant capacity advantage for dough, effortlessly handling hundreds of pounds in a single batch. This capability can turn a production bottleneck into a streamlined operation. While a planetary mixer can knead dough, a spiral mixer does it better, in larger quantities, and with less wear on the machine. If dough is central to your business, this specialization pays for itself in quality and speed. Ready to find the perfect mixer for your operation? Contact us and we'll help match you with the right machine for your specific needs.

Decoding the Specs: Key Features of an Industrial Stand Mixer

Once you've decided between a planetary and spiral model, it's time to understand the technical specifications. Buying based on price alone is a common mistake that leads to owning a mixer that can't keep up with demand or is oversized for your needs. The specs tell you whether a particular industrial stand mixer will be a reliable workhorse or a source of frustration.

We focus on five critical specifications: bowl capacity, motor horsepower, transmission type, speed controls, and attachment compatibility. These elements determine if a mixer can handle your recipes efficiently and consistently for the long haul.

| Feature | Countertop (5-20 qt) | Bench (20-40 qt) | Floor (40-140+ qt) |

|---|---|---|---|

| Capacity | Small batches | Medium batches | Large, continuous batches |

| HP Range | 1/4 - 1 HP | 1 - 2 HP | 2 - 5+ HP |

| Transmission | Often belt-driven for smaller, gear-driven for higher-end | Predominantly gear-driven | Exclusively gear-driven |

| Footprint | Compact | Moderate | Significant |

The key is to honestly assess your current volume and project your growth. A good rule of thumb is to choose a mixer where your typical batch fills about 60% of the bowl's capacity. This provides room for expansion without ingredients splashing over the sides.

Capacity and Size: From Countertop to Floor Models

Bowl capacity, measured in quarts (qt), is the most visible spec. The right capacity depends on your largest typical batch size. The 60% fill rule is crucial: overfilling leads to uneven mixing, while underfilling wastes capacity.

- Countertop mixers (5-20 qt) are perfect for smaller operations or specialized tasks. They sit on a counter and typically run on standard 120V power.

- Bench mixers (20-40 qt) are workhorses for medium-volume operations, suitable for busy bakeries or restaurants. They often sit on reinforced stands and may require more robust electrical connections.

- Floor mixers (40-140+ qt) are built for high-volume production. These machines require significant floor space and dedicated electrical circuits (often 220V or higher).

Investment scales with capacity, but so does production capability. Ready to find the perfect capacity for your operation? Contact us and we'll help you calculate your needs based on your menu and volume.

Motor Power and Transmission: The Heart of Your Mixer

Motor power and transmission type are the most important specs for longevity and performance.

Motor horsepower (HP) indicates the raw power for mixing thick doughs. A 10-quart mixer might have a 3/4 HP motor, while a 30-quart model usually has 2 HP for the torque needed for bread dough. Stiff, low-hydration doughs put the most stress on the motor.

Transmission type is critical. A gear-driven transmission uses interlocking metal gears to deliver superior torque and durability, making it standard on quality professional mixers. A belt-driven transmission, found in some smaller models to keep costs down, uses rubber belts that can slip, stretch, or break under heavy loads, leading to maintenance costs and downtime.

Electrical requirements are a practical consideration. Smaller models use standard 120V outlets, but larger mixers often require 208V, 220V, or even three-phase power. Always verify your facility's electrical service before purchasing to avoid unexpected installation costs.

Speed Controls, Attachments, and Hubs

Speed controls and attachments determine a mixer's versatility. Most planetary mixers offer fixed speeds (typically 3-4 settings optimized for different tasks) or variable speed control for finer adjustments. Many modern units also include digital timers to automate mix times and ensure consistency.

Standard attachments for planetary mixers include:

- Dough Hook: For kneading bread and pizza dough.

- Flat Beater: An all-purpose tool for batters, cookie dough, and creaming.

- Wire Whip: For aerating light mixtures like cream and egg whites.

Many mixers also feature a front-mounted attachment hub. This power takeoff (PTO) port is designed to drive specialized, mixer-specific attachments, further extending the machine's utility. This feature allows a single motor to power various functions without cluttering your workspace with separate appliances, maximizing the value of your investment.

Safety, Sanitation, and Maintenance: Protecting Your Investment

An industrial stand mixer is a substantial investment that requires proper care to deliver years of reliable service. This means creating a culture of safety and preventive maintenance to protect both your equipment and your team. A well-maintained mixer not only lasts longer but also produces more consistent results, operates more safely, and saves you money by preventing costly emergency repairs.

Essential Safety and Sanitation Features

When evaluating mixers, safety and sanitation features should be a top priority. These are not just regulatory checkboxes; they are critical for a safe and hygienic operation.

- Bowl Guards: These wire or plastic covers prevent hands or utensils from entering the bowl during operation.

- Safety Interlock Systems: These systems prevent the mixer from starting unless the bowl is locked in place and the guard is closed.

- Overload Protection: This feature automatically shuts down the mixer if the motor overheats or is under excessive strain, preventing damage.

- Emergency Stop Button: A clearly marked button allows for immediate shutdown in an emergency.

- NSF and ETL Certification: NSF certification ensures the mixer meets public health standards for cleanability and food safety. You can explore the specific standards at NSF International's food equipment standards. ETL certification confirms that electrical components meet North American safety standards.

- Easy-to-Clean Design: Look for stainless steel construction with smooth, seamless surfaces that are easy to wipe down. Removable components make daily cleaning faster and more thorough.

Maintenance Best Practices for Longevity

Your industrial stand mixer will only be as reliable as the care you give it. Establishing solid maintenance routines from day one will mean fewer breakdowns and a longer equipment lifespan.

- Daily Cleaning: After each use, wash the bowl and attachments thoroughly. Wipe down the mixer frame and controls with a damp cloth. Ensure all parts are dry before storage.

- Regular Inspections: For belt-driven models, check weekly for belt wear. For all mixers, listen for unusual grinding noises that could signal a problem. Inspect electrical cords for any damage.

- Proper Lubrication: Follow the manufacturer's guidelines for lubrication. Over-lubricating can attract dust and food particles, causing more harm than good.

- Avoid Overloading: Always respect the mixer's stated capacity limits. Pushing the machine beyond its design limits will strain the motor and transmission, leading to expensive repairs.

- Staff Training: Ensure every operator understands proper use, cleaning procedures, and safety protocols. Trained staff can prevent misuse and catch potential problems early.

These practices quickly become routine and are essential for protecting your investment. Ready to find the right mixer for your operation? Contact us for expert guidance on selecting and maintaining the perfect industrial stand mixer for your kitchen.

Making the Right Choice for Your Budget

When investing in an industrial stand mixer, it's crucial to look beyond the initial price tag. The goal isn't to find the cheapest option but to find the mixer that delivers the best long-term value for your specific situation.

The price for these mixers is vast, with basic countertop models starting around $800 and high-capacity floor units exceeding $30,000. This reflects enormous differences in capacity, power, and durability. The cheapest mixer is rarely the most economical choice. An underpowered unit bought to save money initially will likely need replacement within a couple of years, negating any upfront savings and causing costly downtime.

The real question is: "What's the right mixer that will serve my business for years to come?"

Consider the upfront cost versus long-term value. A higher-quality industrial stand mixer with a gear-driven transmission and durable construction might cost more initially, but if it lasts ten years with minimal repairs while a budget alternative fails after three, the math is clear. The extra investment often proves to be the smarter financial decision.

Warranty considerations are a key part of your analysis. A comprehensive warranty is a manufacturer's vote of confidence in its product. Read the fine print to understand what is covered and for how long. This warranty is designed to protect your business investment, so be sure to operate the equipment accordingly.

Financing options can make it possible to acquire the right equipment without depleting your working capital. Many suppliers, including The Restaurant Warehouse, offer financing programs that allow you to spread the investment over manageable monthly payments. This can be the difference between settling for adequate equipment and investing in machinery that truly supports your growth.

The sweet spot is where your production needs, quality requirements, and budget align. It's about understanding what your operation requires today and where you plan to be in a few years, then selecting equipment that supports that trajectory.

At The Restaurant Warehouse, we pride ourselves on offering affordable, wholesale pricing. We skip the high commissions and overhead costs, passing those savings directly to you. This means you can often step up to a higher-quality mixer than you thought your budget would allow.

Ready to find the perfect mixer for your operation? Explore our affordable range of professional-grade mixers, from compact countertop models to powerful floor units, all priced to support your success. Contact Us for a personalized quote custom to your specific production needs and budget.

Frequently Asked Questions about Industrial Stand Mixers

When making the jump to professional-grade equipment, certain questions come up again and again. Here are practical answers to the most common concerns about choosing an industrial stand mixer.

What size mixer do I need for my small bakery?

Getting the capacity right is crucial. Start by determining your largest typical batch size, considering your projected growth over the next six months. Apply the 60% rule: your batch should fill the bowl to about 60% of its total capacity. This leaves room for proper mixing and prevents strain on the motor.

For most small bakeries, a 20 to 30-quart planetary mixer hits the sweet spot. This size is versatile enough for various recipes without taking up excessive space, and it provides room to grow. Being realistic about your volume is key to making the right choice.

Can I use a large home mixer instead of a professional one?

While tempting, it's not a viable long-term solution. High-end domestic mixers are not engineered for the continuous, heavy-duty operation of a professional kitchen. An industrial stand mixer features a more powerful motor, a durable all-metal gear-driven transmission, and robust construction designed to withstand constant use. Using a domestic mixer in a professional setting will lead to premature failure from motor burnout or stripped gears, and it will void the warranty. For safety, efficiency, and longevity, a professional-grade unit is essential.

How do I know if I need a planetary or a spiral mixer?

The choice comes down to your primary products. If your menu is diverse—cakes, batters, frostings, and occasional dough—a versatile planetary mixer is your answer. Its interchangeable attachments can handle a wide range of tasks.

However, if your business is built on high-volume production of bread or pizza, a spiral mixer is the superior investment. Its gentle kneading action develops gluten perfectly without overheating the dough, resulting in a noticeably better product texture and rise. If over 70% of your mixer's work will be dough, the specialization of a spiral mixer is the strategic choice.

If you're still unsure, reach out to us at The Restaurant Warehouse. We're happy to walk through your specific menu and production volume to help you make the right call. Contact Us for personalized guidance on selecting the perfect industrial stand mixer for your operation!

Conclusion

Choosing the right industrial stand mixer is more than an equipment purchase; it's an investment in the foundation of your food business. This decision will shape your production capacity, product quality, and profitability for years to come.

We've covered the critical distinctions between versatile planetary mixers and specialized spiral mixers. We've decoded the specifications that matter, from motor power and bowl capacity to the superiority of gear-driven transmissions. We've also emphasized that safety features and proper maintenance are not optional—they are essential practices that protect your team and your investment.

An industrial stand mixer represents a real financial commitment, but the cheapest option rarely proves to be the most economical. The right mixer—one that matches your production needs and growth plans—pays for itself through increased output, reduced labor, and the consistency that builds customer loyalty.

Your business deserves equipment that works as hard as you do. A properly selected industrial stand mixer doesn't just mix ingredients; it multiplies your capacity, standardizes your quality, and frees up your time to focus on growing your business. It transforms hours of manual labor into an efficient, scalable process.

Ready to take your production to the next level? Browse our selection at The Restaurant Warehouse and equip your kitchen with professional-grade machinery at wholesale prices that respect your budget. Our team has guided countless businesses through this transition. Contact us today for personalized recommendations to help you make the smartest investment for your culinary future.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment