Energy Efficient Commercial Refrigeration: Save Costs Now

When you hear "energy-efficient commercial refrigeration," it’s easy to think of it as just a fancy, more expensive cooler. But that's not the whole story. It's really about making a strategic investment in your business—one designed to cut down your operating costs by using smarter technology to dial back electricity use. We're moving beyond just basic cooling and into a world of high-performance compressors and top-tier insulation that directly boosts your profitability.

The Hidden Costs of Outdated Refrigeration

For any restaurant or foodservice business, refrigeration is a non-negotiable expense that runs around the clock. But what if your coolers are quietly siphoning off your profits every single day? The financial drain from inefficient commercial units often flies under the radar, lost in the noise of a high utility bill.

Think of an old refrigerator like a car with a slow, steady fuel leak. It still gets you where you need to go, but it costs you a small fortune in wasted resources along the way. That aging reach-in cooler or walk-in freezer isn't just an asset on your books; it's a liability that silently eats up cash through sky-high energy use, frequent repair calls, and the constant risk of food spoilage.

The True Price of Inefficiency

The scale of this issue is bigger than most people realize. In many foodservice and retail businesses, commercial refrigeration is one of the biggest energy hogs, responsible for somewhere between 40% to 60% of total energy consumption. This makes it the perfect place to look for cost-saving opportunities that can seriously improve your bottom line.

And the expenses don't stop at the electricity meter. Older units often run on refrigerants that are being phased out because of environmental regulations.

An inefficient cooler hits your business from multiple angles. It drives up your energy bill, leads to higher maintenance costs, increases the risk of food waste, and grows your carbon footprint—affecting both your finances and your brand's reputation.

Beyond just the energy use, understanding refrigerant phase-outs like R22 and what's replacing them can uncover other hidden costs. As these older chemicals become harder to find and more expensive, just servicing your legacy equipment can turn into a major financial headache.

Let's take a quick look at how the costs stack up over a year.

Annual Operating Costs Traditional vs Efficient Refrigeration

This table gives you a snapshot of how upgrading to a modern, energy-efficient system can translate into real savings on your utility bills.

| Feature | Traditional Refrigeration | Energy-Efficient Refrigeration |

|---|---|---|

| Compressor Type | Standard Efficiency Compressor | High-Efficiency Variable Speed Compressor |

| Insulation | Standard Polyurethane Foam | High-Density, Foamed-in-Place Insulation |

| Lighting | Fluorescent Bulbs | LED Lighting |

| Refrigerant | Older (e.g., R22, R404A) | Modern, Low-GWP (e.g., R290) |

| Estimated Annual Energy Cost | ~$900 - $1,500+ per unit | ~$500 - $800 per unit |

| Annual Maintenance | Higher (More frequent component failure) | Lower (Designed for longevity & efficiency) |

As you can see, the difference isn't trivial. The savings from just one upgraded unit can add up to hundreds of dollars each year, and that's before factoring in lower maintenance needs and potential rebates.

A Strategic Investment Not a Luxury

Viewing an upgrade to energy-efficient commercial refrigeration isn't about buying a luxury item; it's a critical business decision. This guide is your roadmap to understanding the technology, calculating the real-world savings, and making an informed choice that will pay you back for years. We'll break down how modern equipment can:

- Slash Overhead: Directly lower those monthly utility bills.

- Drive Profitability: Free up cash that was previously being wasted.

- Improve Reliability: Cut down the risk of costly breakdowns and emergency service calls.

By the time we're done, you'll see your refrigeration not just as a cost center, but as a genuine opportunity for smart, strategic growth.

What Makes a Refrigerator Energy Efficient

So, what’s the real difference between a modern, high-performance cooler and an old energy-guzzling one? It all comes down to a handful of smart technological upgrades designed to get the job done with less electricity. An energy efficient commercial refrigeration unit isn't just a box that gets cold; it’s a finely tuned system where every part works together to slash waste and boost performance.

Getting a handle on these features helps you look past the price tag and see the long-term value. Once you can read a spec sheet, you can confidently pick a machine that will actively save you money every single month it's plugged in. Let's break down the components that turn a standard cooler into a cost-cutting machine for your kitchen.

The Smart Heart of the System: The Compressor

The compressor is the heart of any refrigeration system, pumping the refrigerant that pulls heat out of the cabinet. Old-school compressors work on a simple on/off cycle, kind of like a drag racer. They either blast at full power or they’re completely off—there’s no middle ground.

This constant stop-and-start process is incredibly inefficient. It leads to wider temperature swings and puts a ton of strain on the machinery, which means higher energy bills and more frequent breakdowns.

Modern energy efficient commercial refrigeration units use a much smarter approach with variable-speed compressors, sometimes called inverter compressors. Think of this like the cruise control in your car. Instead of flooring the gas and then slamming on the brakes, it makes tiny, constant adjustments to maintain a steady speed.

The compressor runs continuously at lower, shifting speeds, using only the exact amount of power needed to hold the target temperature. This smooth, consistent operation can cut a compressor's energy use by as much as 30-40%, leading to serious savings and a longer life for your equipment.

The Unseen Hero: High-Performance Insulation

What’s keeping the cold air in is just as important as what’s making it. The better a refrigerator can trap cold air and block warm air, the less its compressor has to work. This is where insulation becomes a huge factor in overall efficiency.

Older or cheaper units often use standard foam insulation, which can break down over time and create gaps. High-efficiency models, on the other hand, rely on high-density, foamed-in-place polyurethane.

Think of this advanced insulation as a premium thermal jacket for your cooler. It creates a seamless, airtight barrier that dramatically reduces thermal bridging—the transfer of heat through the cabinet walls. A higher insulation R-value directly translates to less energy needed to maintain a cold interior.

Advanced Features That Drive Savings

Beyond the core components, a few other key features contribute to a unit’s overall efficiency. These innovations target specific areas of energy loss, and the savings really add up over the life of the appliance.

- Low-Emissivity (Low-E) Glass Doors: For display coolers, the glass itself can be a major source of heat transfer. Low-E glass has a microscopically thin, transparent coating that reflects heat. It acts like a pair of high-tech sunglasses for your cooler, blocking incoming heat while keeping the cold locked inside.

- Intelligent Defrost Cycles: Traditional freezers run defrost cycles on a fixed timer, whether they need it or not. This wastes energy by heating the coils for no reason. Smart, or "adaptive," defrost systems use sensors to kick off a defrost cycle only when frost has actually built up, running the system far more efficiently.

- Eco-Friendly Refrigerants: Modern units now use natural refrigerants like R290 (propane). Not only does R290 have a very low Global Warming Potential (GWP), but it also has fantastic thermodynamic properties. It absorbs heat more effectively, allowing the system to cool down faster and run less often.

- LED Lighting: This is a simple but powerful upgrade. LED lights use up to 75% less energy than old-school fluorescent bulbs and, just as important, they produce almost no heat. Less heat inside the cabinet means the compressor works less, compounding your energy savings.

How to Calculate Your Return on Investment

Talking about benefits is one thing, but seeing the actual numbers is where the upgrade from old to new really clicks. Calculating the financial impact of investing in energy efficient commercial refrigeration isn't just for accountants; it’s a practical skill every restaurant owner should have. It empowers you to build a rock-solid case for replacing that old, power-hungry unit, turning a potential expense into a predictable, profit-boosting investment.

The key is to translate the numbers on a spec sheet or an ENERGY STAR label into real dollars and cents. Once you understand a couple of simple terms and formulas, you can forecast your savings with confidence and see exactly when your new equipment will start paying you back. Let's walk through how to figure out your annual savings and determine that all-important payback period.

Understanding the Key Metrics

Before you can crunch any numbers, you need to know what you're looking for. The two most important figures for estimating your energy costs are kilowatt-hours (kWh) and your local electricity rate.

Think of a kilowatt-hour (kWh) as the standard unit of energy your utility company uses to bill you—just like a gas station bills by the gallon. An ENERGY STAR label or the manufacturer's spec sheet will give you an estimated annual kWh consumption for a specific model. Your electricity rate is the price you pay per kWh, which you can find right on your monthly utility bill, usually listed in cents per kilowatt-hour.

Once you have these two numbers, the basic calculation for annual energy cost is super straightforward.

Annual Energy Cost = Annual kWh Consumption × Cost per kWh

This simple formula is the foundation for comparing the running cost of your old, inefficient unit against a new, energy-saving model. The difference between those two numbers is your potential annual savings.

A Step-by-Step Guide to Calculating Savings

Let’s put this into practice with a real-world scenario. Imagine your small cafe has an old reach-in cooler that eats up around 3,500 kWh per year. A new ENERGY STAR certified model of the same size is rated at just 2,100 kWh annually.

-

Find Your Electricity Rate: First, grab the cafe's utility bill. Let's say your commercial electricity rate is $0.15 per kWh.

-

Calculate the Old Unit's Annual Cost: Multiply the old cooler's consumption by your rate.

- 3,500 kWh × $0.15/kWh = $525 per year

-

Calculate the New Unit's Annual Cost: Do the same for the new, efficient model.

- 2,100 kWh × $0.15/kWh = $315 per year

-

Determine Your Annual Savings: Finally, just subtract the new cost from the old cost.

- $525 - $315 = $210 in annual savings

This single upgrade would save the cafe $210 every year on its power bill alone. That doesn't even factor in potential savings from fewer maintenance calls or any utility rebates you might qualify for.

Calculating the Payback Period

Knowing your annual savings is great, but the next question is always, "How long until this thing pays for itself?" This is where the payback period calculation comes in, and the formula is just as simple.

- Payback Period (in years) = Initial Investment Cost / Annual Savings

To figure this out, you need the upfront cost of the new unit. For a comprehensive look at what new equipment costs, our commercial refrigerator price guide can give you some valuable insights into current market rates.

Let’s stick with our cafe example. Suppose the new ENERGY STAR refrigerator costs $2,500. We already know the annual savings are $210.

-

Payback Period Calculation:

- $2,500 / $210 per year = 11.9 years

Now, nearly 12 years might seem like a long time. But this calculation is only looking at energy savings. What if you factor in a $300 utility rebate and avoiding just one $200 repair call per year? Suddenly, the equation changes dramatically.

Your "true" annual savings become $410 ($210 in energy + $200 in repairs), and the initial cost effectively drops to $2,200 ($2,500 - $300 rebate).

-

Revised Payback Period:

- $2,200 / $410 per year = 5.3 years

This more realistic calculation shows how rebates and reduced maintenance can cut the payback period in half, making the investment in energy efficient commercial refrigeration a much more attractive and sensible business decision.

Boosting Efficiency with Smart Operations

Putting the right equipment in your kitchen is a huge step, but the journey to peak energy efficiency doesn't stop when the delivery truck pulls away. Even the most advanced cooler in the world can bleed money if it's not managed correctly day-to-day. Think of your smart operational habits as the other half of the efficiency equation—they're what turn a good investment into a great one.

It’s a bit like owning a high-performance car. You can have the best engine and aerodynamics on the market, but if you’re constantly slamming on the gas and hitting the brakes, you’ll never get anywhere near its best mileage. In the same way, how your staff interacts with your refrigeration units and how you maintain them can dramatically impact your monthly utility bills. These low-cost, high-impact routines are absolutely essential for maximizing performance and protecting your investment.

The Power of Routine Maintenance

Simple, consistent maintenance is hands down the most effective way to keep your refrigeration running efficiently and head off expensive breakdowns. Just like cleaning the lint trap in your dryer, these small tasks prevent the system from working much harder than it needs to.

A dirty condenser coil, for example, forces the compressor to run longer and hotter just to get rid of heat, which causes a big spike in energy use. Forgetting this simple task is like forcing a marathon runner to wear a heavy winter coat in July—eventually, the system is going to overheat. You can find a complete rundown in our guide on how to maintain commercial refrigerators to keep your equipment in top shape.

Globally, the refrigeration sector is a major energy consumer. It accounts for about 20% of worldwide electricity consumption and 7.5% of global CO₂ emissions. Simple operational changes, when adopted across the industry, can make a real difference. You can learn more from the International Institute of Refrigeration's brief on the role of refrigeration in the global economy.

Creating an Efficiency Checklist

Good habits start with a clear, simple checklist that your entire team can get behind. These daily and weekly practices make sure nothing gets missed and that everyone understands their role in keeping costs down.

Your Daily & Weekly Efficiency Checklist:

- Check Door Seals: Grab a dollar bill and slide it between the door and the gasket. If it pulls out with no resistance, the seal is weak and leaking cold air, forcing the unit to overwork.

- Keep Coils Clean: Regularly wipe down condenser and evaporator coils to get rid of the dust and grease that can build up, act like insulation, and trap heat.

- Mind the Temperature: Use a separate thermometer to double-check that temperatures are in the safe zone but not colder than they need to be. Every degree of unnecessary cooling adds to your energy bill.

- Load Smart: Don't cram the shelves full. Always leave some space around products to let air circulate properly, which helps the unit cool everything down evenly and efficiently.

- Cool Before Storing: Never put hot food straight into the cooler. Let it cool to room temperature first to lighten the load on the compressor.

Beyond manual checks, you can also bring in tech like Variable Frequency Drives (VFDs) to dial in your efficiency. To get a better handle on how these can lead to real savings, check out a practical guide to VFD energy savings for a deeper dive. By combining great hardware with smart daily habits, you can unlock the full potential of your energy-efficient refrigeration.

Should You Retrofit or Replace Your Cooler?

It’s one of the toughest calls a business owner has to make: do you breathe new life into an aging piece of equipment, or is it time to start fresh? When it comes to your commercial refrigeration, this decision hits your immediate budget and your long-term operating costs right where it counts. Do you upgrade your existing cooler, or is it time for a full replacement?

There isn’t a single right answer here, but there is a smart way to think about it. It’s a lot like deciding whether to renovate an old house or build a brand-new one. A renovation can be faster and cheaper upfront, fixing the most pressing problems. Building new, on the other hand, guarantees everything is up to modern code, perfectly efficient, and built to last for decades. Both paths have their merits.

Understanding the Retrofit Option

Retrofitting is all about upgrading specific parts of a mechanically sound unit to give it an efficiency boost. This is often a great short-term solution to lower your energy bills without the huge capital expense of buying a brand-new cooler. It’s the perfect choice when the core of your unit—like the main compressor and the cabinet structure—is still in good shape.

Common retrofitting projects include:

- Installing LED Lighting: Swapping out old fluorescent bulbs for LEDs is a quick win. It immediately cuts lighting energy use and reduces the heat inside the cabinet, which eases the load on your compressor.

- Replacing Fan Motors: Upgrading to modern electronically commutated motors (ECMs) can slash fan energy consumption by as much as 70%.

- Adding New Gaskets: A simple gasket replacement is a cheap and easy fix that eliminates cold air leaks, one of the biggest sources of energy waste in older units.

When a Full Replacement Makes More Sense

Replacing your unit is a strategic, long-term investment. Yes, the upfront cost is higher, but a new piece of energy efficient commercial refrigeration guarantees you’re getting peak performance, total reliability, and compliance with the latest environmental standards. This is the smartest move when your old cooler is starting to show its age with frequent breakdowns or consistently high energy bills.

A new model brings comprehensive efficiency from the ground up, with better insulation, an advanced compressor, and modern refrigerants all working together in perfect harmony.

To help you decide which path makes the most sense, the table below breaks down the key factors.

Decision Matrix: Retrofit vs. Replace

| Consideration | Best for Retrofitting | Best for Replacing |

|---|---|---|

| Age of Unit | Younger than 10 years and still mechanically sound. | Over 10-15 years old, nearing the end of its expected lifespan. |

| Repair History | Infrequent, minor repairs. The core system is reliable. | Frequent breakdowns or recurring issues with major components. |

| Upfront Budget | Limited capital available for a large purchase. | Access to financing or rebates that make a new unit affordable. |

| Long-Term Goals | Focused on immediate cost reduction and short-term efficiency gains. | Focused on sustainability, brand image, and minimizing long-term costs. |

| Efficiency Needs | Looking for moderate energy savings from targeted upgrades. | Aiming for maximum energy efficiency and compliance with modern standards. |

| Condition | The cabinet, insulation, and compressor are in good shape. | The cabinet is damaged, insulation is poor, or the compressor is failing. |

Ultimately, whether you retrofit or replace, you're making a choice that will impact your business for years. A careful review of these points against your current situation will lead you to the most profitable decision.

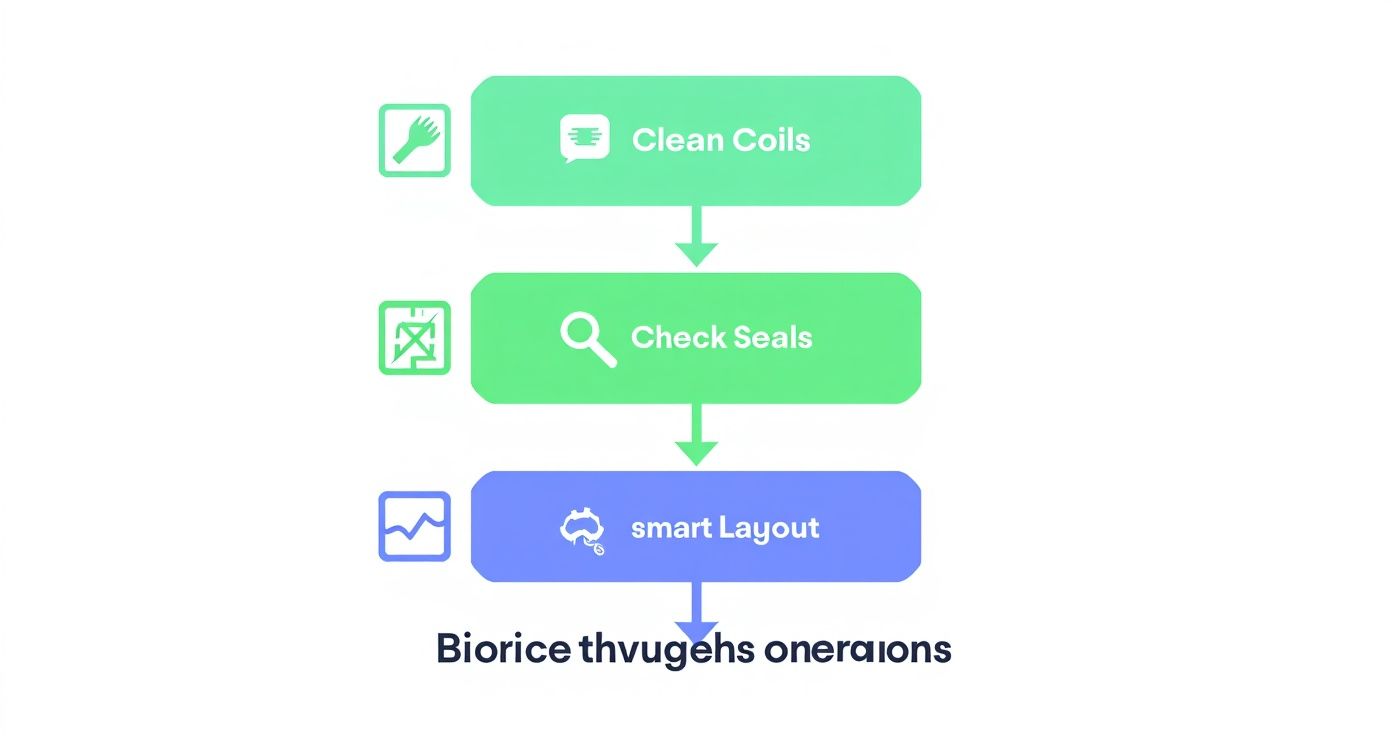

No matter which route you choose, some maintenance fundamentals are non-negotiable for keeping any cooler running efficiently.

This workflow highlights the foundational tasks—cleaning coils, checking seals, and using smart layouts—that are vital for maintaining efficiency, whether your unit is old or new.

Key Questions to Guide Your Decision

To make the best choice, you need to look at your equipment's history and your business's future. Ask yourself these critical questions:

How old is the unit? If your cooler is over 10-15 years old, its core components are nearing the end of their expected lifespan. A replacement is often the safer, more reliable bet.

What is the repair history? If you're constantly calling for service on the same unit, those repair bills are adding up. A new cooler with a warranty can provide peace of mind and predictable costs.

What is your budget? Retrofitting is less expensive upfront. However, if you have access to financing or utility rebates, the total cost of ownership for a new, highly efficient unit can be surprisingly low.

What are your future business goals? If you plan to expand or are focused on building a sustainable brand, investing in modern, compliant, and energy efficient commercial refrigeration aligns with those long-term objectives.

Choosing between these two options is really about balancing short-term costs with long-term gains. If you do decide a replacement is in order, understanding your options is the next critical step. For more on this, check out our guide covering commercial freezer sizes and energy savings to find the perfect fit for your operation.

How to Choose the Right Refrigeration Partner

Picking out new equipment is a big decision, but choosing the right supplier is just as critical. The best partner does more than just sell you a box; they act as a guide, helping you navigate the complexities of energy efficient commercial refrigeration to find a solution that genuinely fits your business. A great supplier is invested in your success, providing the tools, selection, and support you need to make a smart, profitable investment.

Making an informed choice means looking beyond the sticker price. You need a partner who is transparent with their product specs, giving you a clear view of performance metrics and what you can expect in long-term operating costs. That clarity is what allows you to confidently compare models and ensures you get the efficiency you're paying for.

What to Look for in a Supplier

A top-tier supplier should offer a broad selection of equipment from trusted, industry-leading brands. This is important because it means you have access to the latest innovations and can find a unit that perfectly matches your specific needs for capacity, footprint, and features. A shallow inventory just limits your options and can corner you into a less-than-ideal solution.

Beyond the products themselves, look for value-added services that simplify the whole process and protect your investment. These are the tell-tale signs of a supplier who is truly committed to their customers' operational success. Key things to look for include:

- Accessible Financing: Flexible financing and lease-to-own options are huge for managing cash flow. They make it possible to get high-quality, efficient equipment without a massive upfront capital expense.

- Fast, Reliable Shipping: In this business, every day your kitchen is without proper refrigeration is a day of lost revenue. A partner with a solid logistics network and multiple distribution centers can minimize that downtime by getting your equipment to you quickly.

- Expert Support: Whether you have a question about a spec sheet or need help deciding between two models, being able to talk to a knowledgeable support staff is invaluable.

A Partnership for Long-Term Success

The right partner understands that your purchase is just the beginning of a long-term relationship. They provide the resources you need to ensure your equipment runs efficiently for years to come, helping you maximize your return on that investment.

Choosing a supplier is about finding an ally who understands the fast-paced nature of the food service industry and is equipped to help you succeed. Their job is to make buying and running your equipment as seamless and cost-effective as possible.

The market for this technology is growing fast. The global commercial refrigeration sector, valued at around $42.94 billion in 2024, is set to expand as more businesses recognize the savings and reliability that efficiency brings. You can explore more about these commercial refrigeration market insights to get a feel for the industry's direction.

At The Restaurant Warehouse, we pride ourselves on being that kind of strategic partner. We combine a curated selection of top-tier energy efficient commercial refrigeration with flexible financing and rapid, nationwide delivery, making sure you have the support you need to thrive.

Frequently Asked Questions

When you start digging into energy efficient commercial refrigeration, a lot of practical questions naturally come up. As you weigh the options and think about the investment, you want clear, straight answers. This section is here to tackle some of the most common questions we hear from business owners, reinforcing the key ideas from this guide to help you feel confident moving forward.

We'll clear up any confusion about payback periods, the real-world cooling power of modern refrigerants, and how tiny details can make a surprisingly big dent in your utility bills.

What Is the Average Payback Period for an Energy Efficient Refrigerator?

This is a great question, and while the exact timeline will shift based on your equipment cost, local electricity rates, and how hard you run it, most businesses see a payback period of 1 to 4 years for an ENERGY STAR certified commercial refrigerator. The monthly savings you see on your utility bill go directly toward paying off that initial investment, making it a pretty predictable financial win.

Think of it this way: if a new unit saves you $50 a month and the price difference was $1,200 compared to a standard model, you've made your money back in just 24 months. When you do that simple math, you can see the clear long-term gain, turning what feels like an expense into an asset that eventually funds itself.

A faster payback period means your new equipment starts generating a positive return that much sooner. When you factor in potential utility rebates and the money you save by avoiding repairs on an old unit, that payback timeline often shrinks even more, making the investment even smarter.

Are Eco-Friendly Refrigerants Less Effective at Cooling?

This is a common myth, and it’s completely understandable why people think it. But the answer is a definite no. Modern, eco-friendly refrigerants like R290 (propane) aren't just better for the environment because of their low Global Warming Potential (GWP); they are also exceptionally good at cooling.

These natural refrigerants actually have better thermodynamic properties, which is a technical way of saying they transfer heat more effectively than the older chemicals they replaced. This leads to faster temperature recovery after you open the door and lower overall energy use compared to legacy refrigerants like R134a. It’s a true win-win: you’re doing right by the planet and your bottom line.

How Much Do LED Lights in a Cooler Really Save?

The savings you get from switching to LED lighting in your cooler are a one-two punch, and they're pretty significant. First, LEDs use up to 75% less energy than the old-school fluorescent bulbs they replace. That’s a direct and immediate drop in your electricity bill right there.

Second—and this is just as important—LEDs generate almost no heat. In a refrigerated space, any heat from the lights forces the cooling system to work harder to compensate. By cutting down on this internal heat load, LEDs reduce how often the compressor has to run, saving even more energy and reducing wear and tear on one of the system’s most critical (and expensive) parts.

Does Leaving the Cooler Door Open for a Few Seconds Matter?

It absolutely does. Every single time that cooler door swings open, a cascade of cold air spills out onto the floor, and it's immediately replaced by warmer, more humid air from your kitchen. The compressor then has to kick into high gear to cool all that new air down, which is an incredibly energy-hungry process.

Leaving a door ajar for even 30 seconds can force the system to run for several minutes just to get back to the right temperature. Over the course of a busy shift, all those little moments of wasted runtime add up to a major drain on your energy bill. This is exactly why features like self-closing doors and door alarms aren't just bells and whistles; they're essential tools for maintaining efficiency and controlling your operating costs.

Ready to slash your utility bills and upgrade your kitchen with reliable, high-performance equipment? At The Restaurant Warehouse, we offer a wide selection of top-tier energy-efficient commercial refrigeration designed to save you money. Explore our inventory and find the perfect fit for your business today at https://therestaurantwarehouse.com.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment