Deck Out Your Pizza Game with These Commercial Pizza Ovens

Why Deck Ovens Deliver Authentic Pizza Results

A deck oven for pizza uses direct stone-to-dough contact and radiant heat to create the crispy, charred crust that customers expect from authentic pizzerias. Here's what makes them essential for serious pizza operations:

Key Benefits: - High heat capability - Reaches 800°F+ for fast baking and proper crust development - Stone deck surface - Absorbs moisture for crispy bottoms while retaining heat - Modular stacking - Triple-stack configurations maximize output in small footprints - Independent controls - Each deck operates at different temperatures simultaneously - Energy efficient - Direct heat transfer reduces cooking times and operating costs

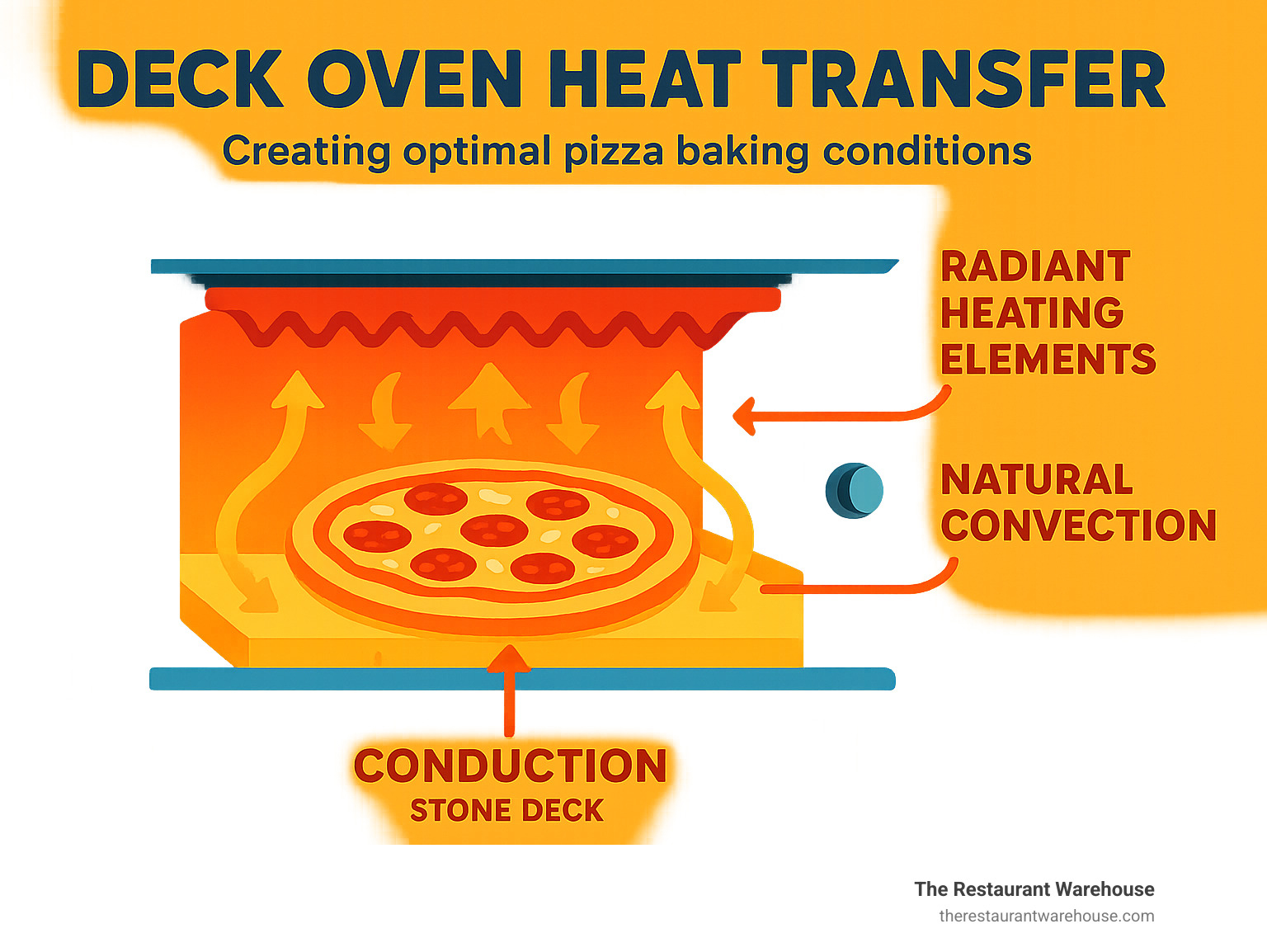

Unlike conveyor or convection ovens that rely on forced air, deck ovens use three heat sources: conduction from the hot stone surface, radiation from the ceiling, and gentle natural convection that won't dry out delicate toppings.

Deck ovens have been commercial kitchen workhorses for decades - some models stay in service for 50+ years without major problems. For budget-conscious restaurant owners, this durability translates to lower total cost of ownership.

Modern deck ovens can bake 12 ten-inch pizzas or 6 fourteen-inch pizzas per section, with recovery times fast enough to handle dinner rush volumes. Stack two or three sections for serious production capacity without the massive footprint of traditional brick ovens.

Deck oven for pizza definitions: - commercial deck oven - commercial smoker oven

Why Choose a Deck Oven for Pizza?

Picture Friday night: your dining room is packed, your deck oven for pizza is humming at 800°F, and you’re sliding out perfect pies every 90 seconds. That reliability is what separates winning pizza shops from the rest.

A deck oven combines conduction, radiation, and natural convection. When dough hits the pre-heated stone, crust forms instantly as moisture is drawn away for a crispy base. Radiant ceiling heat browns cheese and toppings without harsh air currents.

Those high, even temperatures trigger the Maillard reaction, producing the flavor and color customers crave. Because each deck stores massive thermal energy, the oven recovers quickly, so quality stays consistent through any rush.

How a deck oven for pizza works

The stone hearth acts like a thermal battery, releasing stored heat throughout service. Independent top and bottom elements let you fine-tune crust versus topping doneness, while slightly porous cordierite decks absorb excess moisture for extra crunch. Modern models add bottom air intakes for gentle circulation and spring-assist doors that cut heat loss and staff fatigue.

Advantages over convection & conveyor ovens

Forced-air convection ovens can blow toppings around and dry out cheese. Conveyor units rarely pass 600°F, limiting crust development. A deck oven delivers intense energy density—up to 85,000 BTU/hr per section— so it rebounds quickly even when you load several pies at once. The gentle heat also preserves delicate flavors and lets you bake bread or roast proteins during slower periods. More info about Convection Ovens Guide

Types of Commercial Deck Ovens

Choosing the right deck oven for pizza starts with understanding your options. There's probably a perfect configuration for your kitchen, whether you're running a cozy neighborhood pizzeria or a high-volume operation cranking out hundreds of pies per night.

The main decision points come down to fuel type, size, and how much flexibility you need for future growth. Gas models bring serious heat with their high BTU output and typically lower operating costs. Electric versions offer precise temperature control and work great when gas lines aren't practical.

Then there's the question of modular versus fixed installations. Modular systems let you start small and grow - perfect for testing the waters without a massive upfront investment. Countertop models fill a sweet spot for smaller operations or when you need extra capacity during rush periods.

Stackability is where deck ovens really shine for space-conscious operators. Most commercial units stack two to four high, turning a small floor footprint into serious production capacity.

Gas vs. Electric: choosing the right power source

The gas versus electric debate usually comes down to three factors: what utilities you have available, local operating costs, and how much control you want over different cooking zones.

Gas deck ovens for pizza pack a punch with BTU ratings up to 140,000 per deck. That translates to lightning-fast heat recovery when you're loading pizza after pizza during dinner rush. The high heat output also means you can maintain those crucial 800°F+ temperatures even with frequent door openings.

Electric models excel at precision and flexibility. You can set each deck to a different temperature, which opens up interesting possibilities. Maybe you're running thin-crust pizzas at 850°F on the top deck while baking focaccia at 450°F on the bottom.

| Feature | Gas Deck Ovens | Electric Deck Ovens |

|---|---|---|

| Heat Output | Up to 140,000 BTU/hr | Up to 25 kW |

| Temperature Control | All decks same temp | Independent deck control |

| Operating Cost | Generally lower | Varies by local rates |

| Installation | Requires gas line & venting | Needs high-amp electrical |

| Recovery Time | Very fast | Moderate to fast |

| Humidity Control | Natural moisture retention | Precise steam injection available |

Operating costs vary wildly depending on where you're located. In some areas, natural gas is dirt cheap. In others, electricity might be the more economical choice. It's worth running the numbers based on your local utility rates before making a decision.

Modular, Fixed & Countertop Configurations

Modular deck ovens solve a problem every restaurant owner has faced: getting equipment through a standard doorway. These systems break down for shipping and go back together in your kitchen, making installation possible even in tight spaces or upstairs locations.

The modular approach also makes financial sense for growing businesses. Start with a single deck to test demand, then add sections as your volume grows. This staged approach keeps your initial investment manageable.

Fixed installations offer maximum thermal efficiency. The continuous insulation and sealed construction minimize heat loss, which translates to lower operating costs over time. The trade-off is less flexibility - you need to get the sizing right from the start.

Countertop models have carved out their own niche. They're perfect for small-volume operations, specialty shops, or as backup capacity during peak periods. Modern countertop deck ovens for pizza can handle pizzas up to 16 inches while still reaching the high temperatures needed for authentic results.

Space planning goes beyond just the oven footprint. You need clearances for loading pizzas, maintenance access, and staff movement. That triple-stack configuration might fit your floor space perfectly, but consider whether your shorter team members can comfortably load the top deck during a busy shift. Deck the Halls (and Your Bakery) with These Commercial Deck Ovens

Key Features to Compare Before You Buy a Deck Oven for Pizza

When investing in a deck oven for pizza, zero in on the features that directly affect output and long-term cost.

- Temperature range: Look for at least 550°F—and ideally 800°F+—with fast recovery under load.

- Deck material: Dictates crust quality and durability.

- Capacity & zone controls: More decks mean higher volume; separate controls let you handle multiple pizza styles simultaneously.

Deck Materials and Their Impact on Pizza Quality

- Cordierite stone: Wicks moisture, withstands thermal shock, delivers crisp crusts.

- Natural stone: Old-world charm but needs careful maintenance.

- Steel: Heats fastest and is nearly indestructible, though it doesn’t absorb moisture.

- Ceramic: Balances heat retention and easy cleaning.

Hot, slightly porous surfaces like stone or ceramic create ideal conditions for the Maillard reaction that makes pizza crust taste amazing. Scientific research on Maillard reaction

Sizing & Capacity Planning

Size the deck about 1.5× your largest pie. A 48-inch deck holds four 12-inch pizzas or two 16-inch pies and, at 800°F, can turn out 20–40 pizzas per hour. Stack multiple decks to multiply capacity without expanding your floor footprint. Allow roughly 36–48 inches in front for loading and 12–18 inches on the sides for maintenance.

Installation, Venting & Utilities Checklist

Gas ovens generally need a Type I hood; electric models often qualify for simpler Type II hoods, and some advanced electric units are completely ventless. Maintain required clearances (6–18 inches from combustibles), verify gas pressure or electrical amperage before delivery, and consider modular shipping to move large ovens through standard doorways.

Operating, Cleaning and Maintaining Your Deck Oven

Taking care of your deck oven for pizza doesn't have to be complicated, but it does require some specific knowledge to keep everything running smoothly. Think of it like caring for a cast iron skillet - with the right routine, your oven will actually get better with age.

The most important habit you can develop is a consistent daily brush routine. While your stone deck is still warm (but cool enough to work safely), use a stiff-bristled brush to sweep away flour, cheese bits, and any other debris. This warm cleaning method actually works better than trying to scrub a cold deck later.

Stone curing is something many operators overlook, but it's crucial for long-term performance. New stone decks need time to develop their seasoning, just like a good pizza stone at home. During the first few weeks of operation, your stones will gradually absorb oils and develop a natural non-stick surface that actually improves pizza quality over time.

Regular gasket checks might seem tedious, but they're your best defense against skyrocketing energy bills. Those rubber door seals take a beating from constant opening and closing. A worn gasket can let precious heat escape, forcing your oven to work harder and driving up operating costs.

Thermostat calibration ensures you're actually getting the temperatures you think you are. Even quality ovens can drift over time, and a 50-degree difference can mean the difference between perfect pizza and customer complaints.

Common Mistakes to Avoid with a Deck Oven for Pizza

Even experienced operators can fall into traps that damage their deck oven for pizza or compromise food quality. Most of these mistakes are easily preventable once you know what to watch for.

Skipping the full preheat is probably the most expensive mistake you can make - not in terms of repair costs, but in lost customer satisfaction. Your deck oven needs time to reach thermal equilibrium throughout the entire stone mass, not just the surface. This process takes 60-90 minutes depending on your oven's size. Rushing this step results in uneven baking.

Never, ever wash stone decks with water. This bears repeating because it's such a common and costly mistake. Stone decks are porous and will absorb water, which can cause explosive steam formation or cracking when you heat the oven back up. Stick to dry cleaning methods - brushing, scraping, and using the oven's residual heat to break down stubborn deposits.

Overcrowding might seem like a good way to maximize capacity during busy periods, but it actually backfires. Packed pizzas don't cook evenly, and the time you save by cramming in extra pies gets lost when you have to remake orders or deal with unhappy customers.

Ignoring insulation damage is like throwing money out the window. Cracked or damaged insulation doesn't just waste energy - it can create dangerous hot spots on the oven exterior and make your kitchen uncomfortably warm.

Multi-Use Cooking: Beyond Pizza

Your deck oven for pizza really starts to pay for itself when you realize it can handle an impressive range of other menu items, turning your oven into a true workhorse.

Artisan bread baking works beautifully in deck ovens, especially during off-peak hours when you can take advantage of residual heat. The thermal mass of stone decks provides the steady, even heat that creates proper crust development in sourdough and other artisan breads.

Pastry production benefits from the precise temperature control that deck ovens provide. Delicate items like croissants and puff pastry need consistent heat without the harsh air circulation that convection ovens create.

Roasted vegetables and proteins can transform your pizza shop into a more complete dining destination. That same high heat that makes your pizza crusts crispy also creates beautiful caramelization on roasted vegetables and proteins.

This menu versatility is one of the strongest arguments for investing in a quality deck oven system. Instead of buying separate specialized equipment for different cooking tasks, one well-chosen deck oven can handle multiple roles throughout your operating day. Commercial Bakery Equipment Guide

Frequently Asked Questions About Deck Ovens for Pizza

What temperature should a deck oven for pizza reach for authentic results?

The temperature you need depends entirely on the style of pizza you're making. Think of temperature as the secret ingredient that separates good pizza from truly memorable pizza.

For authentic Neapolitan pizza, your deck oven for pizza needs to hit the 800-900°F range. These blazing temperatures create those beautiful leopard spots on the crust and allow for the classic 90-second bake time that makes Neapolitan pizza so special.

New York-style pizza works best at a more moderate 550-650°F. This temperature range gives you enough heat for proper crust development while ensuring your toppings cook through evenly. You'll get that perfect balance of crispy bottom and foldable flexibility that defines a great New York slice.

Chicago deep-dish and other thick-crust varieties actually prefer lower temperatures around 450-550°F. The thicker dough needs time to cook all the way through without burning the outside.

Here's the crucial part: it's not just about reaching these temperatures - it's about maintaining them under load. A quality deck oven should bounce back to your target temperature within minutes after loading, not struggle to recover heat during your dinner rush.

Can I bake bread and pastries in the same deck oven without flavor transfer?

Absolutely! This is one of the biggest advantages of investing in a quality deck oven for pizza - the versatility pays for itself quickly when you can use the same equipment for multiple menu items.

The high temperatures in deck ovens actually work in your favor here. The intense heat naturally burns off residual flavors and aromas between different baking sessions. It's like the oven cleans itself of lingering tastes with each high-heat cycle.

Stone and ceramic decks are particularly good at preventing flavor transfer. The porous surface actually helps by absorbing moisture and volatile compounds during baking, then releasing them during the high-heat process.

Smart scheduling makes all the difference. Save your stronger-flavored items like garlic pizza or heavily spiced breads for the end of your baking cycle. Follow up with thorough brushing while the deck is still warm, and you're ready for neutral items like plain pizza dough or basic artisan breads.

Do electric deck ovens always require a hood or can they be ventless?

This is where electric deck ovens really shine compared to gas models. You have much more flexibility when it comes to venting requirements, which can save you thousands in installation costs.

Many electric deck ovens for pizza qualify for Type II hoods (the simpler condensate hoods) instead of the expensive Type I exhaust systems that gas ovens require. But here's the exciting part - some advanced electric models are completely ventless and don't need any external exhaust connection at all.

Ventless electric deck ovens are engineering marvels. They use sophisticated filtration systems with catalytic filters, condensing chambers, and sometimes even UV sterilization to clean the air internally. The steam, smoke, and cooking odors get captured and processed right inside the unit.

Your local codes ultimately determine what's allowed in your area. Some health departments require exhaust hoods for all commercial cooking equipment regardless of fuel type, while others accept ventless technology for qualifying electric units.

The benefits of going ventless extend way beyond installation savings. You'll avoid the ongoing costs of makeup air systems, reduce your HVAC loads, and gain incredible flexibility in where you can place equipment in your kitchen layout.

Conclusion

Choosing the right deck oven for pizza isn't just about buying equipment - it's about investing in your restaurant's ability to create memorable dining experiences that keep customers coming back. The authentic flavors, crispy textures, and artisanal appearance that only come from proper stone deck baking can transform a good pizza into something truly special.

We've covered everything from understanding how heat transfer creates perfect crusts to navigating the practical details of installation and maintenance. The beauty of deck ovens lies in their simplicity - they've been perfecting pizza for generations using the same basic principles of stone, fire, and time.

Your success depends on matching the right equipment to your specific needs. A small neighborhood pizzeria has different requirements than a high-volume sports bar or a bakery adding pizza to their evening menu. Take time to honestly assess your peak capacity needs, available space, and long-term growth plans before making your decision.

The numbers tell a compelling story. Quality deck ovens often operate reliably for 30-50 years with proper care. Compare that to other commercial cooking equipment that might need replacement every 10-15 years, and the long-term value becomes clear.

At The Restaurant Warehouse, we've seen how the right equipment can make or break a foodservice operation. That's why we focus on wholesale pricing that eliminates the markup you'd pay elsewhere. When you're already investing in quality equipment that will serve your business for decades, why pay retail prices?

The versatility factor shouldn't be overlooked either. The same deck oven for pizza that handles your dinner rush can bake fresh bread for morning service, roast vegetables for lunch specials, or create dessert pizzas for special occasions. This multi-use capability helps maximize your return on investment.

Ready to move forward? Start by measuring your kitchen space and identifying your utility connections. Then think through your peak volume requirements - how many pizzas do you need to produce during your busiest hour? These practical considerations will guide you toward the right size and configuration.

Installation planning is just as important as equipment selection. Factor in venting requirements, electrical needs, and staff workflow when finalizing your layout. A perfectly capable oven in the wrong location can create operational headaches that affect your entire kitchen's efficiency.

The pizza industry continues growing, with consumers increasingly seeking authentic, high-quality experiences over mass-produced alternatives. A quality deck oven positions your operation to meet this demand while maintaining the production efficiency needed for profitable operations. Pizza Restaurant Business Plan

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment