A Guide to Commercial Kitchen Layout Design

A well-thought-out commercial kitchen layout design is more than just a floor plan—it's the very blueprint for your restaurant's success. It dictates workflow, how efficiently your staff operates, and ultimately, your profitability. This isn't just about where you place the equipment; it's about creating a smart, intuitive system that supports your menu and service style from the moment an order comes in to the second a plate goes out.

Why Your Kitchen Layout Is Your Most Important Tool

Before you even think about buying a single piece of equipment, your first and most critical investment should be in planning. A great commercial kitchen layout design is the central nervous system of your entire operation. It's the unseen force that keeps chaos at bay during a frantic dinner rush and empowers your team to work together like a well-oiled machine.

Think about it this way: a poorly designed kitchen forces staff into constant, wasted motion. You’ll see them crossing paths while carrying hot pans, trekking across the kitchen for a stored ingredient, or creating a logjam at the dishwashing station. These seemingly small hiccups compound quickly, leading to slower service, a higher risk of accidents, and frustrated employees. A smart layout simply gets rid of these friction points.

The Foundation of an Efficient Kitchen

The whole game is about creating a logical flow for food. Your design needs to map out a clear, one-way journey for ingredients, from the second they're dropped at the receiving door to the final, beautifully plated dish that lands on a customer's table. This fundamental path is what prevents dangerous cross-contamination between raw and cooked foods and keeps the entire kitchen moving forward.

This process boils down to creating distinct, well-defined work zones:

- Receiving and Storage: This is where all your ingredients arrive, get inspected, and are put away in dry storage, refrigerators, or freezers.

- Food Preparation: You'll want dedicated areas for washing, chopping, and mixing. It's best practice to keep prep for raw meats separate from produce.

- Cooking Line: The heart of the kitchen. This is where your ranges, ovens, fryers, and grills are arranged for maximum output and efficiency.

- Service Area: The final stop where dishes are plated, garnished, and picked up by your front-of-house team.

- Warewashing: The cleaning zone for all dishes, cookware, and utensils, strategically placed to avoid re-contaminating clean prep areas.

A layout that doesn't respect the natural progression of food through these zones is just setting itself up for inefficiency. The goal is to minimize steps and create an environment so intuitive that every team member knows exactly where they need to be and what they need to do.

It’s clear that operators are taking this seriously. The global market for professional kitchen design services, which absolutely includes commercial kitchen layout design, was valued at around $20.5 billion in 2023. It’s projected to climb to nearly $33 billion by 2032. This trend shows just how critical a good layout is viewed as a core business investment. If you're curious, you can get more details on these market trends.

To get started, it helps to understand the foundational layout styles and which one might be the best fit for your space. Each has its own strengths depending on your kitchen's size and the kind of menu you're running.

Common Kitchen Layouts and When to Use Them

This table offers a quick comparison of the most common commercial kitchen layout styles and their ideal applications. Use it to help identify the best starting point for your own space and concept.

| Layout Type | Best For | Key Advantage |

|---|---|---|

| Assembly Line | Quick-service restaurants, concepts with a simple, linear menu (e.g., pizza, burritos). | Speed and Efficiency: Creates a highly streamlined, step-by-step workflow for high-volume production. |

| Island | Larger kitchens with ample square footage and a head chef who needs to oversee multiple stations. | Centralized Command: The central "island" (often for cooking) becomes the hub, improving communication and flow. |

| Zone-Style | Restaurants with diverse menus requiring multiple prep types (e.g., separate bakery, grill, and garde manger). | Organized Specialization: Each zone functions as a self-contained station, preventing workflow conflicts. |

| Galley | Long, narrow kitchen spaces, often found in smaller restaurants or food trucks. | Space Optimization: Makes the most of limited square footage by placing workstations along two parallel walls. |

| Open Kitchen | Concepts where the cooking process is part of the dining experience; chef-driven restaurants. | Entertainment and Transparency: Creates a dynamic atmosphere and builds trust with diners who can see their food being prepared. |

Choosing the right foundational layout gives you a solid framework. From there, you can customize it to perfectly match your menu, equipment, and the unique rhythm of your kitchen team.

Designing Your Core Workflow Zones

An efficient kitchen just flows. It doesn’t clash. The real secret to a successful commercial kitchen layout isn't just about a floor plan; it’s about mapping out the distinct zones where every single stage of production happens. Getting this right creates a logical, one-way workflow that cuts down on dangerous traffic and the risk of cross-contamination.

Think of it like choreographing a dance. Each member of your team has their own space, their own tools, and a clear path to follow. This deliberate movement is what turns a potentially chaotic space into a high-functioning engine, especially when the ticket machine starts firing on all cylinders.

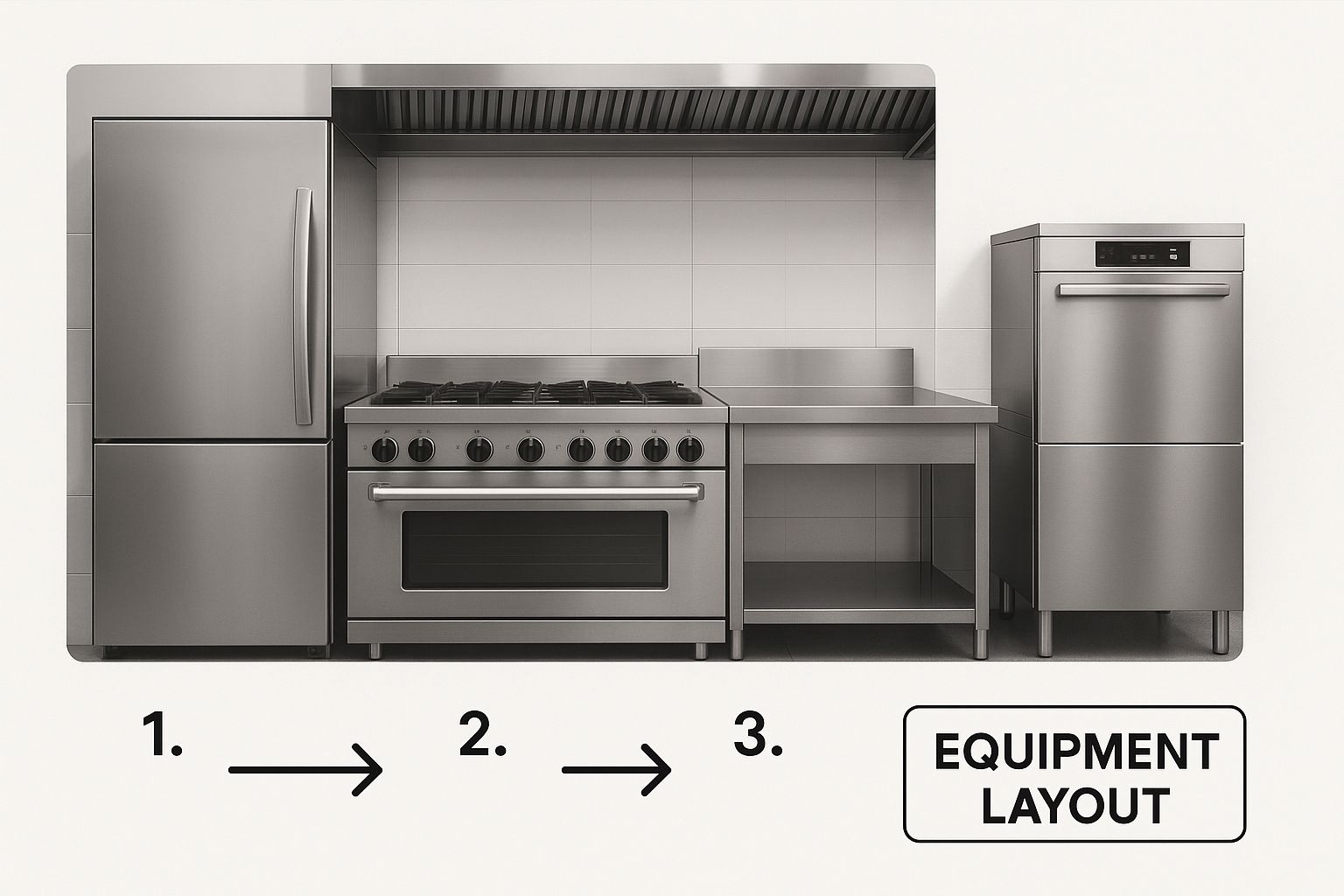

The image below really brings this to life, showing how a thoughtful approach to equipment layout becomes the backbone of these work zones.

As you can see, strategically placed stainless-steel appliances create a natural progression. This setup guides the flow of work from one station to the next without a single wasted step.

Mapping the Essential Kitchen Zones

Your kitchen's layout should be built around five core zones. The trick is to arrange them in a way that supports a linear path, moving from raw ingredients to finished plates.

- Receiving and Storage: This is your command center. It needs to be right near a delivery entrance for easy unloading. Right next to it, you'll want your dry storage racks, walk-in coolers, and freezers. The goal here is simple: get products inspected and stored with as little travel time as possible.

- Preparation: This is where the magic starts—washing produce, butchering meats, and mixing ingredients. You'll need sinks, plenty of counter space (stainless steel is your best friend here), and quick access to cold storage. For food safety, it's absolutely critical to create separate sub-zones for raw proteins and ready-to-eat items.

- Cooking Line (The "Hot Line"): The heart of the kitchen. This is where you'll group your primary cooking equipment: ranges, fryers, griddles, and ovens. The arrangement has to be logical. For example, placing a griddle right next to a fryer makes total sense for a burger station. Proper ventilation hoods are completely non-negotiable here.

- Service and Plating: Located near the exit to the dining room, this is the final stop before food goes out. It needs heat lamps, plating surfaces, and space for garnishes. The "expo" window, where servers pick up orders, is the crucial link between your back-of-house and front-of-house teams.

- Warewashing: This area has to handle a constant flow of dirty dishes from the dining room. It requires a three-compartment sink for washing, rinsing, and sanitizing, plus a commercial dishwasher. Crucially, it needs to be placed so that dirty dishes enter without ever crossing the path of clean, plated food heading out to customers.

The real magic happens when these zones don't just exist but connect seamlessly. A prep cook shouldn't have to walk through the hot line to get to the walk-in. A server shouldn't have to dodge the dish pit to pick up an order.

Adapting Zones to Your Concept

Of course, the size and importance of each zone depend entirely on your menu. A high-volume pizzeria, for instance, will dedicate a massive amount of space to its dough prep and oven areas. A cozy café, on the other hand, might have a smaller cooking line but a much more elaborate service station for assembling complex coffee drinks and pastries.

Drafting a detailed outline is a crucial first step in this process. For more in-depth guidance on turning these ideas into a solid blueprint, you can learn a ton from a well-structured commercial kitchen floor plan. Properly planning these zones on paper first will save you from incredibly costly and disruptive changes down the road.

Choosing and Placing Your Kitchen Equipment

Alright, this is where your kitchen design really starts to feel real. Moving from a blueprint on paper to selecting actual, tangible equipment is a huge step. This isn't just a shopping trip; it's more like solving a strategic puzzle where every single piece of gear has to fit perfectly, both in the space you have and in the way your team will use it.

The right equipment, placed with real thought, is what ultimately brings your workflow zones to life and gives your staff the tools they need to shine.

Your menu is the ultimate guide here. A steakhouse is going to obsess over high-powered charbroilers and salamanders, while a bakery’s world revolves around oven capacity and proofing cabinets. You also have to be honest about your projected volume. An appliance that can keep up during your first week might be completely swamped six months down the line. Always, always plan for growth.

And before you hit "purchase" on anything, measure everything—twice. I'm talking about the equipment's dimensions, the footprint it will take up, and the clearance needed on every side for proper ventilation and maintenance access. A classic rookie mistake is forgetting to measure the doorways and hallways, which can turn delivery day into an absolute nightmare.

Planning for Utilities and Grouping

Every piece of cooking equipment has a lifeline—gas, water, or electricity. You have to map out these utility connections with total precision. An oven that requires a 240V outlet is nothing more than a very expensive paperweight if you only planned for a 120V connection. Getting this right from the start saves you from costly, last-minute calls to electricians and plumbers.

From there, you can start grouping equipment into logical “pods” or stations. This is a core principle for any efficient kitchen layout. By putting related equipment together, you create powerful, self-contained work areas that drastically cut down on how much your staff has to move around.

Think about a classic "hot line" pod, for instance. It might look something like this:

- Fryers: For knocking out fries, wings, and all your other fried appetizers.

- Griddle/Flattop: The go-to for searing burgers, cooking pancakes, or toasting buns.

- Charbroiler: Absolutely essential for getting that perfect grilled flavor on steaks and chicken.

- Range: Your workhorse with burners for sautéing sauces and vegetables.

Placing these side-by-side, often with refrigerated prep tables directly across from them, lets a single chef juggle multiple orders without taking more than a step or two. To really get into the weeds on picking the right pieces, check out our comprehensive commercial kitchen equipment guide for more detailed insights.

Maximizing Every Inch of Space

Floor space is always at a premium, but don't forget to look up. Vertical space is your secret weapon for fighting clutter and staying organized. Wall-mounted shelving right above your prep tables is perfect for holding frequently used spices, tools, and small wares, which keeps your countertops clear for the actual work.

Pro Tip: Leverage under-counter space to its absolute maximum. Installing under-counter refrigerators and freezers directly on the cooking line keeps critical ingredients within arm's reach, saving your team countless trips to the walk-in during a chaotic service.

Finally, ventilation is completely non-negotiable. Your exhaust hood needs to be sized correctly, extending beyond the footprint of your cooking equipment on all sides. An undersized or poorly placed hood won't just get you a failing grade on a health inspection; it will create a hot, smoky, and genuinely unsafe work environment for your staff.

Designing a Modern, Sustainable Kitchen

A modern commercial kitchen is about more than just a slick layout; it’s about creating an operation that’s smart, sustainable, and built for the future. This means thinking beyond today's service and weaving in strategies that save you money, shrink your environmental footprint, and keep you ready for whatever the industry throws at you next.

The core idea is simple: do more with less. Instead of cramming your line with single-purpose appliances, savvy operators are all about multi-function equipment. A combi-oven, for instance, can take on the roles of a convection oven, steamer, grill, and even a proofer, replacing several bulky units. This move alone frees up a ton of precious floor space, but it also slashes energy use and makes your team's workflow much simpler.

Weaving Sustainability into Your Kitchen Design

Making sustainability a priority in your kitchen layout isn't just a feel-good decision—it's a seriously smart business move that cuts down on your long-term operating costs. And it all starts with your equipment choices.

Make a point to actively look for appliances with the ENERGY STAR® certification. These models are specifically engineered to use less electricity and water, which translates directly to lower utility bills, month after month. Yes, the initial investment might be a little higher, but the ROI from the energy savings is huge. A professional commercial energy audit can be a game-changer here, pinpointing exactly where the biggest opportunities for savings are in your unique kitchen.

Beyond the big-ticket items, think about waste management right from the drawing board. Your layout needs to have clearly defined, integrated stations for:

- Recycling: For all that cardboard, glass, and plastic.

- Composting: To handle organic food scraps.

- Waste: For everything else that can't be recycled.

When you place these stations strategically within the kitchen’s natural flow—like near prep areas and the dish pit—proper disposal becomes an automatic habit for your staff, not an afterthought.

Carving Out a Dedicated Takeout and Delivery Zone

The explosion of off-premise dining isn't just a fleeting trend; it's a permanent shift in how people eat. A truly modern kitchen has to be designed for this reality. Trying to manage a constant stream of delivery and takeout orders through your main service line is a recipe for chaos, frustrating both your kitchen crew and your dine-in servers.

The real solution is to design a dedicated zone just for these off-premise orders. Ideally, this area should have easy access for delivery drivers, keeping them out of your main dining room and away from the host stand. It needs its own packing station stocked with all the necessary supplies, a holding area with heat lamps to keep food at the perfect temperature, and its own order management screen (KDS).

This separation is absolutely critical. It allows your dine-in service to run like a well-oiled machine, while a dedicated team can efficiently manage the high volume of off-premise orders, ensuring every bag goes out fast and accurate.

This kind of flexible thinking is quickly becoming the new standard. In fact, as of 2023, modular layouts and versatile equipment are now commonplace for adapting to menu pivots and scaling operations. Smart technology, like IoT sensors and connected devices, now even allows for real-time monitoring and predictive maintenance, trimming costs and preventing downtime. By embracing these modern design principles, you’re not just building a kitchen that’s efficient for today—you’re building one that’s ready for whatever comes next.

Meeting Health Codes and Safety Standards

Let's be honest: a brilliant commercial kitchen layout is completely worthless if it fails inspection. Navigating the tangled web of health codes, safety rules, and ADA compliance isn't just a box you have to check—it’s the foundation that protects your team, your customers, and your business from some very serious risks.

I've seen too many operators treat these regulations as annoying hurdles. The smart move is to see them as a blueprint for a safer, more efficient workspace. These aren't just random rules; they're built on decades of data about preventing everything from foodborne illness to nasty workplace accidents. One of the best pieces of advice I can give is to engage with your local health department early in the design process. It will save you from incredibly expensive and frustrating redesigns down the road.

Core Compliance and Safety Must-Haves

While the specifics can change a bit from city to city, there are several non-negotiable elements that are pretty much universal. Your design absolutely must account for these from day one if you want a smooth opening and safe daily operations.

Here are the key areas you need to nail:

- Proper Clearances: You have to maintain specific clearances around cooking equipment for fire safety and to give your team room to clean properly. This usually means a minimum of 36 to 48 inches for your main traffic aisles.

- Handwashing Stations: Health codes demand dedicated handwashing sinks—totally separate from food prep or dishwashing sinks—placed in convenient spots for your staff. They must be fully stocked with soap, paper towels, and the correct signage.

- Fire Suppression Systems: A certified fire suppression system is mandatory above all equipment that produces heat and grease. This includes having an appropriately sized ventilation hood with an integrated sprinkler system.

- ADA Compliance: Your kitchen has to be accessible. This involves providing enough aisle width for wheelchair access and making sure at least some work surfaces are at an accessible height.

An unsafe kitchen is an inefficient one. It’s no surprise that poor workflow directly contributes to injuries. The U.S. Bureau of Labor Statistics reported a staggering 93,800 nonfatal injuries in full-service kitchens in 2019 alone. A better layout isn't just about safety; some studies suggest it can boost productivity by up to 50%.

Building a Safe Environment from the Ground Up

Passing your initial inspection is just the start. Your layout should actively encourage a culture of safety, and that means looking at the physical environment itself. The right materials and infrastructure play a huge role in preventing those everyday slips, trips, and falls.

For example, non-slip

Got Questions? We’ve Got Answers.

Even the most meticulously planned commercial kitchen layout can leave you with a few head-scratchers. It’s a complex project, and questions are a normal part of the process. Getting these common concerns sorted out early can save you from costly headaches down the road and give you the confidence to keep moving forward. Let's dive into some of the most frequent questions we hear from restaurant owners.

The single biggest mistake I see? It's always underestimating the space needed for your support zones. People get laser-focused on the flashy cooking line—the grills, the fryers, the ranges—and treat receiving, storage, and dishwashing as an afterthought. That’s a recipe for chaos.

Think about it. A cramped receiving area creates an instant bottleneck every time a delivery truck shows up. Not enough storage leads to inventory nightmares and serious food safety risks. And a poorly placed dish pit? You'll have a constant traffic jam of dirty plates coming in and clean plates going out, slowing down service and creating a huge risk for cross-contamination.

Always, always design for a logical, circular flow. Raw goods come in, move through prep and cooking, go out to the dining room, and dirty dishes return to the warewashing area—all without these paths crossing more than absolutely necessary. Skimping on space for these "unseen" areas will cripple your kitchen's efficiency when you're deep in the weeds on a busy Friday night.

How Much Should I Budget for a Kitchen Build-Out?

This is the million-dollar question, and honestly, the answer varies wildly depending on your location, the size of your space, and the equipment you choose. As a general rule of thumb, though, you should expect to budget anywhere from $250 to over $1,000 per square foot.

A simple build-out in a space that already has good bones—plumbing, electrical, and basic infrastructure in place—will land on the lower end of that spectrum. But if you're starting from scratch in a major city and need to install all new plumbing, electrical, and a serious ventilation system, you'll easily push past that $1,000 mark.

Here’s what will eat up most of your budget:

- Equipment: Brand-new gear is a major expense. Don't be afraid to look at high-quality used equipment to find some significant savings.

- Ventilation: Your hood and exhaust system can be one of the single most expensive parts of the entire build-out. Don't underestimate this cost.

- Trades: Licensed plumbers, electricians, and HVAC technicians are worth every penny, but their costs add up fast.

- Finishes: Things like commercial-grade flooring, durable wall coverings, and stainless steel countertops all contribute to the final bill.

My best advice? Get multiple, detailed quotes from experienced contractors and—this is critical—keep a contingency fund of at least 15-20% set aside. You will have unexpected costs. Plan for them.

How Do I Plan a Layout for a Changing Menu?

In today's fast-moving food world, flexibility is everything. The key is to build versatility into your kitchen from day one.

Prioritize modular and mobile equipment wherever you can. Think work tables on casters instead of fixed, built-in islands. This lets you reconfigure your prep areas in minutes to handle a new menu item or a special event.

Another smart move is investing in multi-purpose equipment. A combi-oven, for example, can steam, roast, bake, and even grill, giving you incredible flexibility without hogging the floor space of four separate appliances.

When you're planning your utilities, consider adding a little more capacity than you think you need right now. "Future-proofing" your commercial kitchen layout design like this means you can adapt to new culinary trends or even a complete concept pivot down the road without having to rip everything out and start over.

Ready to equip your new kitchen with durable, affordable equipment? The Restaurant Warehouse offers everything you need, from high-performance cooking lines to essential refrigeration and worktables. We provide flexible financing options and fast delivery to get your operation up and running. Visit us at https://therestaurantwarehouse.com to build the kitchen of your dreams.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment