The Ultimate Guide to Buying Used Restaurant Equipment

Let's reframe what "used" means in a professional kitchen. It doesn't mean worn out—it means proven. Opting for used restaurant equipment is your secret pass to acquiring higher-quality, more durable brands for a fraction of the sticker price. This isn't just about cutting costs. It's a strategic move that lowers your financial risk and can seriously speed up your path to profitability. You get the workhorse oven or the ultra-reliable freezer you've been dreaming of, putting you ahead of the game from day one. The key is knowing how to spot the real deals from the duds.

Think of it as a smart, sustainable way to build a high-performance kitchen without completely draining your capital before you even open the doors.

Why Buying Used Restaurant Equipment is a Smart Move

Choosing pre-owned equipment isn't just a budget move; it’s a core strategy that seasoned pros use for long-term success. The most obvious benefit, of course, is the massive cost reduction. A top-tier commercial range or walk-in cooler can set you back tens of thousands of dollars new. A well-maintained used model? You could snag it for 50-70% less. That kind of financial breathing room is critical, especially during the high-stakes startup phase.

Those immediate savings free up cash to be used where it has the biggest impact—like creating a standout menu, investing in marketing to build that initial buzz, or hiring and training a rockstar staff. It's all about optimizing your resources to build a stronger business from day one.

Get the Best Brands Without the Hefty Price Tag

One of the best reasons for buying used is the access it gives you to superior gear. Your budget for a brand-new, entry-level convection oven might be the same as the price of a used, high-performance workhorse from a premium brand like Blodgett or Southbend.

This access to better equipment translates directly to better performance in your kitchen. Higher-end models almost always mean more durable construction, better temperature consistency, and greater efficiency. That means better food quality, a smoother workflow, and less downtime dealing with frustrating equipment failures.

Used vs. New: Which is Right for Your Kitchen?

Deciding between used and new equipment is a classic restaurant dilemma. While new gear comes with a full warranty and that fresh-out-of-the-box shine, used equipment offers significant cost savings and lets you punch above your weight with premium brands. To help you weigh the options, here's a quick look at the key factors.

How to Decide Between Used and New Equipment

| Factor | Used Equipment | New Equipment |

|---|---|---|

| Initial Cost | Significantly lower, often 50-70% less | High upfront investment |

| Brand Access | Afford top-tier, premium brands | May be limited to entry-level brands on a budget |

| Warranty | Limited or non-existent | Full manufacturer warranty |

| Depreciation | Much slower; holds value better | Depreciates quickly once used |

| Availability | Immediate | Can have lead times or backorders |

| Condition | Varies; inspection is critical | Pristine, unused condition |

Ultimately, the right choice depends on your budget, risk tolerance, and specific needs. A mix of both new and used is often the most practical approach for many new restaurant ventures.

More Than Just Saving Money on a Startup

The benefits of buying used equipment extend far beyond the initial price tag. Opting for pre-owned gear is also an environmentally responsible choice. It reduces manufacturing demand and keeps perfectly functional equipment out of landfills, a practice that supports a more sustainable industry. This eco-friendly approach can become a part of your restaurant's story, appealing to a growing number of diners who prefer to support businesses with a conscience. It’s a simple way to build a positive brand image while making a smart financial decision that sets your business up for long-term success from the very beginning.

Furthermore, used equipment is a shrewder long-term investment because it holds its value far better than new items. A brand-new piece of equipment depreciates significantly the moment it leaves the showroom, much like a new car. Pre-owned gear has already undergone its steepest drop in value, meaning if you decide to upgrade or sell it down the line, you’ll recoup a much larger percentage of your initial cost. This financial stability is crucial for any growing business. Whether you're buying used or exploring affordable new options, the goal is to maximize your investment. Making high-quality equipment accessible is key, which is why options like restaurant equipment financing can be a great tool for managing cash flow effectively.

The Sustainable Choice for a Modern Kitchen

The secondhand market isn't some shady, back-alley operation anymore. It’s a legitimate and booming industry, which is a clear signal that successful restaurateurs see the immense value in pre-owned gear.

The used restaurant equipment market isn't just surviving; it's thriving. Valued at approximately $6.34 billion, the market is projected to grow to $6.84 billion, reflecting a compound annual growth rate (CAGR) of 7.8%.

This growth is fueled by the natural turnover in the foodservice industry and a growing emphasis on sustainability. When you buy used, you’re not only making a sharp financial choice but also a responsible environmental one by giving quality equipment a second life and cutting down on waste. You can find more details about these market trends and what they mean for your business.

At the end of the day, buying used restaurant equipment is about being resourceful. It's a strategic move that empowers you to build the kitchen of your dreams without the crushing financial strain of buying everything new. This approach gives you a real competitive advantage by blending affordability with quality, setting the stage for a resilient and profitable restaurant from the very beginning.

Before You Shop: Create Your Equipment Hit List

Before you even think about scrolling through listings or hitting an auction, the most important work you'll do is on paper. I’ve seen it a hundred times: operators get excited and rush into the market without a clear, detailed plan. It's a surefire way to blow your budget on shiny objects you don’t need while forgetting the items that are absolutely critical.

When you're buying used restaurant equipment, your success starts with a well-researched hit list. This isn't just a simple inventory; it's the strategic blueprint for your entire kitchen. It forces you to connect every single purchase directly to your menu, your projected volume, and the actual physical workflow of your space.

Start with Your Menu, Not the Showroom

The single biggest mistake new operators make is buying equipment before their menu is locked in. Your menu dictates everything. A cozy cafe focused on espresso and baked goods has completely different needs than a steakhouse that requires high-temperature broilers and massive amounts of cold storage.

Go through your menu, item by item. List every single piece of equipment needed to prep, cook, hold, and plate it. Think through the entire journey, from raw ingredient to the finished dish. This nitty-gritty approach is what prevents that "Oh no, I forgot a commercial food processor!" moment a week before you open.

Once you have that master list, split it into two simple groups:

- Must-Haves: These are the non-negotiables. The workhorses. Your business absolutely cannot function without them. This is your primary cooking line, your refrigeration, and your warewashing setup.

- Nice-to-Haves: This bucket holds the items that would be great for efficiency or expanding your menu, but they aren't vital for launch day. Think about a vacuum sealer for a small bistro or a specialty pasta maker—cool, but you can live without it for a while.

This simple act of sorting is your first line of defense against budget overruns. It allows you to focus your initial capital on sourcing the best possible used equipment for your "must-have" list, knowing the "nice-to-haves" can wait until your cash flow improves.

Map Your Kitchen Stations and Workflow

Now, put on your chef hat and visualize your kitchen in action. A logical workflow is the secret sauce for an efficient, safe, and sane kitchen. Your equipment list needs to support that flow, not fight against it.

Literally walk through the journey of an order, from the ticket printer to the pass. This mental exercise helps you pinpoint what’s needed at each station to prevent bottlenecks and chaos during a slammed service.

A well-planned kitchen layout isn't just about convenience; it directly impacts your ticket times and labor costs. Every extra step a cook has to take because a prep table is in the wrong place is a loss of efficiency that compounds over thousands of orders.

Putting It Into Practice: A Cafe Example

Let's make this tangible. Picture a bustling little cafe that's going to serve killer coffee, fresh pastries, and a simple lunch menu of sandwiches and salads.

Must-Have List:

- Commercial Espresso Machine (2-group)

- High-Quality Coffee Grinder

- Convection Oven (for baking pastries)

- Reach-In Refrigerator (for milk, produce)

- Undercounter Refrigerator (for the coffee station)

- Sandwich/Salad Prep Table with refrigeration

- Three-Compartment Sink (for warewashing)

- Handwashing Sinks (as required by health code)

- Ice Machine

Nice-to-Have List:

- Panini Press

- High-Speed Commercial Blender (for smoothies)

- Display Refrigerator (for grab-and-go items)

- Dough Sheeter (if making pastries from scratch)

By creating this tiered list, the cafe owner knows exactly where to focus their energy and money when hunting for used restaurant equipment. They can prioritize finding a reliable used convection oven and espresso machine—the heart of their operation—and hold off on the panini press until the business is on solid ground. This disciplined approach is how you build a kitchen that truly works for your concept and your budget.

Where to Find Quality Used Restaurant Equipment

Knowing where to look is half the battle when you're buying used restaurant equipment. I've seen it time and time again: the right source can mean the difference between landing a reliable workhorse and inheriting someone else's expensive headache. Your goal is to match the right channel to what you need, what you can spend, and how fast you need it.

The landscape for used gear is pretty diverse, ranging from hyper-local online listings to specialized national dealers. Each one has its own rhythm and rules of engagement. Once you understand these nuances, your search will become a whole lot more efficient and successful.

Checking Out Specialized Equipment Dealers

Think of these businesses as the seasoned pros of the secondhand market. Their entire business model is built on buying, refurbishing, and reselling equipment, and their reputation rides on the quality of their inventory. For most operators, this is the safest route, especially for mission-critical pieces like your refrigeration or primary cooking line.

Dealers typically inspect, clean, and repair items before they even hit the sales floor. Many even offer a limited warranty, which is a huge advantage you just won't get from a private seller. A 90-day parts and labor warranty on a used convection oven, for example, provides a crucial safety net. You'll likely pay a bit more here, but that premium often buys you peace of mind and a more reliable product from day one.

Pro Tip: When you're talking to a dealer, don't just ask about the price. Dig deeper. Ask about their refurbishment process. What exactly do they inspect and replace on a used refrigerator? A detailed, confident answer is a great sign you're dealing with a reputable operation.

What to Expect from a Reputable Dealer

A reputable dealer is your safest bet, especially for the heavy hitters in your kitchen. Think of them as the seasoned pros of the secondhand market. Their entire business is built on sourcing, refurbishing, and reselling quality equipment, and their reputation depends on it. This is the route I always recommend for mission-critical pieces like your primary cooking line or commercial refrigerators. You’re not just buying a piece of metal; you’re buying a piece of equipment that has been vetted by someone who knows what to look for. They have the expertise to spot potential issues that you might miss, saving you from a costly mistake down the road.

Understanding Warranties and Guarantees

Here’s one of the biggest perks of working with a dealer: the warranty. This is a massive advantage you simply won’t get from a private seller on Craigslist. A good dealer stands behind their work. While it might not be a full manufacturer's warranty, even a 90-day guarantee on parts and labor provides a crucial safety net. It shows the dealer is confident in their refurbishment process and gives you time to put the equipment through its paces in a real-world kitchen environment. This peace of mind is often worth the slightly higher price tag, especially when you’re making a significant investment.

The Refurbishment Process Explained

So, what does "refurbished" actually mean? For a trustworthy dealer, it’s a comprehensive process. Before a piece of equipment even touches the sales floor, it’s thoroughly inspected, deep-cleaned, and repaired by trained technicians. They replace worn-out parts, test thermostats, check gas lines, and ensure everything is up to operational standards. This meticulous process is what separates a quality used deep fryer from one that’s just been wiped down. Always ask a dealer about their specific refurbishment process—a detailed answer is a great sign you’re working with a true professional.

Look for In-Person Showrooms

While online shopping is convenient, nothing beats seeing a piece of equipment with your own eyes. If you can, find a dealer with a physical showroom. This gives you the chance to open the doors, turn the knobs, and check for any hidden signs of wear and tear. You can get a real feel for the machine’s condition and build quality. It’s also a perfect opportunity to ask the staff detailed questions and get their expert opinion. Being able to physically inspect an item before you buy is one of the best ways to ensure you’re making a smart purchase.

Don't See It Online? Just Ask

A dealer’s website doesn’t always show their full inventory. They are constantly acquiring new pieces, and it can take time to get everything photographed and listed online. If you don’t see the specific model you’re looking for, pick up the phone. Let them know what’s on your hit list. A good dealer will keep an eye out for you and might even have the perfect item sitting in their workshop waiting to be refurbished. Building a relationship with a local dealer can give you first dibs on the best equipment before it even hits the market.

Scoring Deals at Restaurant Auctions

Auctions are where you can find some of the absolute best deals, especially when a restaurant closes and needs to liquidate everything quickly. If you’re patient and prepared, you can score high-quality, lightly used gear for pennies on the dollar. I’ve seen it happen.

But make no mistake, auctions are a high-risk, high-reward game. Equipment is almost always sold "as-is, where-is," with no warranties attached. You absolutely must attend the pre-auction inspection to kick the tires yourself. It’s also incredibly easy to get swept up in the bidding excitement and completely blow your budget. Set a firm maximum price for each item you’re interested in and stick to it, no matter what.

For a deeper dive into the world of pre-owned equipment, our comprehensive used commercial kitchen equipment guide offers even more detailed strategies.

Finding Gems on Online Marketplaces

Platforms like Facebook Marketplace and Craigslist can be absolute goldmines for finding equipment directly from other restaurant owners. This channel offers a huge variety of items, often at great prices because you’re cutting out the middleman entirely.

The key here is extreme diligence. You are entirely responsible for the inspection and verification. When you spot a promising listing, be ready to act fast but be incredibly thorough with your questions:

- Ask for History: "How old is this unit, and how was it used in your kitchen?"

- Request Specifics: "Could you send me a clear photo of the manufacturer's data plate?"

- Inquire About Maintenance: "Do you have any service records or know of any quirks I should be aware of?"

Meeting the seller and seeing the equipment operate in person is non-negotiable. If a seller is hesitant to let you inspect it thoroughly, consider that a major red flag and walk away. Buying directly from a closing business can be a unique opportunity, as you often get to see the equipment in its working environment before it’s moved, which is a massive advantage.

What You Can Find on Marketplaces

The sheer volume of what’s available on a large marketplace like eBay is staggering. You can find everything from major cooking equipment like commercial ovens and deep fryers to smaller essentials like prep tables and shelving. It’s a great resource for both brand-new and used items, often with significant discounts. It’s not uncommon to see listings for heavy-duty ice makers or chafing dishes at 10-15% off their retail price. Beyond the big-ticket items, these platforms are also fantastic for sourcing hard-to-find replacement parts, which can save you from having to replace an entire machine over one broken component.

Understanding Buyer Protection Programs

Buying from an unknown seller online always carries a bit of risk, but major platforms have built-in safety nets to protect you. For instance, eBay offers programs like its "Money Back Guarantee" and "Business Equipment Purchase Protection." These policies are designed to cover you if an item arrives damaged, doesn't match the listing's description, or never shows up at all. This layer of security is a significant advantage over cash-based platforms like Craigslist, where a bad deal often means you’re simply out of luck. Always read the fine print of these programs before you buy, but know that they exist to make your purchase a whole lot safer.

Don't Buy Anything Without This Inspection Checklist

This is the moment where your diligence pays off—literally. A thorough, hands-on inspection is what separates a fantastic deal on used equipment from a future financial headache. It’s about more than just seeing if it powers on. You need to know what the pros look for to spot the difference between a minor cosmetic flaw and a deal-breaking mechanical failure.

Never go to an inspection empty-handed. I always recommend bringing at least two simple tools: a powerful flashlight to see into every dark corner and the back of units, and a good instant-read digital thermometer. These will be your best friends for verifying temperatures and spotting hidden issues.

What to Look for in Used Refrigeration

Refrigeration is the heart of any kitchen. If it goes down, you have a full-blown emergency on your hands. When you’re looking at a reach-in, walk-in, or prep table, your focus needs to be on more than just cold air.

- Gaskets are Gold: Run your fingers along the entire door gasket. You’re feeling for soft, pliable rubber, not something that’s cracked, torn, or brittle. A bad seal makes the compressor run constantly, which wastes a ton of energy and leads to premature failure.

- Listen to the Compressor: A healthy compressor should cycle on and off with a consistent, low hum. If you hear any loud clanking, grinding, or rattling, walk away. Those are the sounds of an expensive repair bill just waiting to happen.

- Check the Coils: Use that flashlight to get a good look at the condenser and evaporator coils. They should be relatively clean. If they’re caked in dust or grease, it means the unit has been struggling to breathe and straining the whole system.

- Test the Temperature: This is where your thermometer comes in. Place it inside, close the door, and give the unit some time to run. A refrigerator should hold steady between 35-40°F, and a freezer needs to be at 0°F or below. Any big swings are a major red flag.

Getting this part right is one of the most important things you can do when buying used. Don’t rush it.

How to Inspect Used Ovens and Cooktops

For ovens, ranges, and griddles, you’re looking for two things: structural integrity and even, functional heating. Hidden rust or faulty fittings can turn a great deal into a dangerous liability pretty quickly.

A common mistake I see people make is just checking if the unit heats up. You need to verify how it heats up. Uneven heating in an oven or cold spots on a griddle will directly impact your food quality and drive your cooks crazy during service.

Bring your thermometer out again. For a convection oven, let it preheat and then check the temperature in multiple spots—center, corners, top, and bottom. A difference of more than 15-20°F points to problems with the circulation fan or the heating elements themselves.

With gas equipment, carefully inspect all the fittings and hoses for any signs of cracking or brittleness. If you smell even a faint whiff of gas when the unit is off, it’s an immediate deal-breaker. No exceptions. Use your flashlight to look deep inside oven cavities and underneath ranges for hidden rust or corrosion that could compromise the unit's structure.

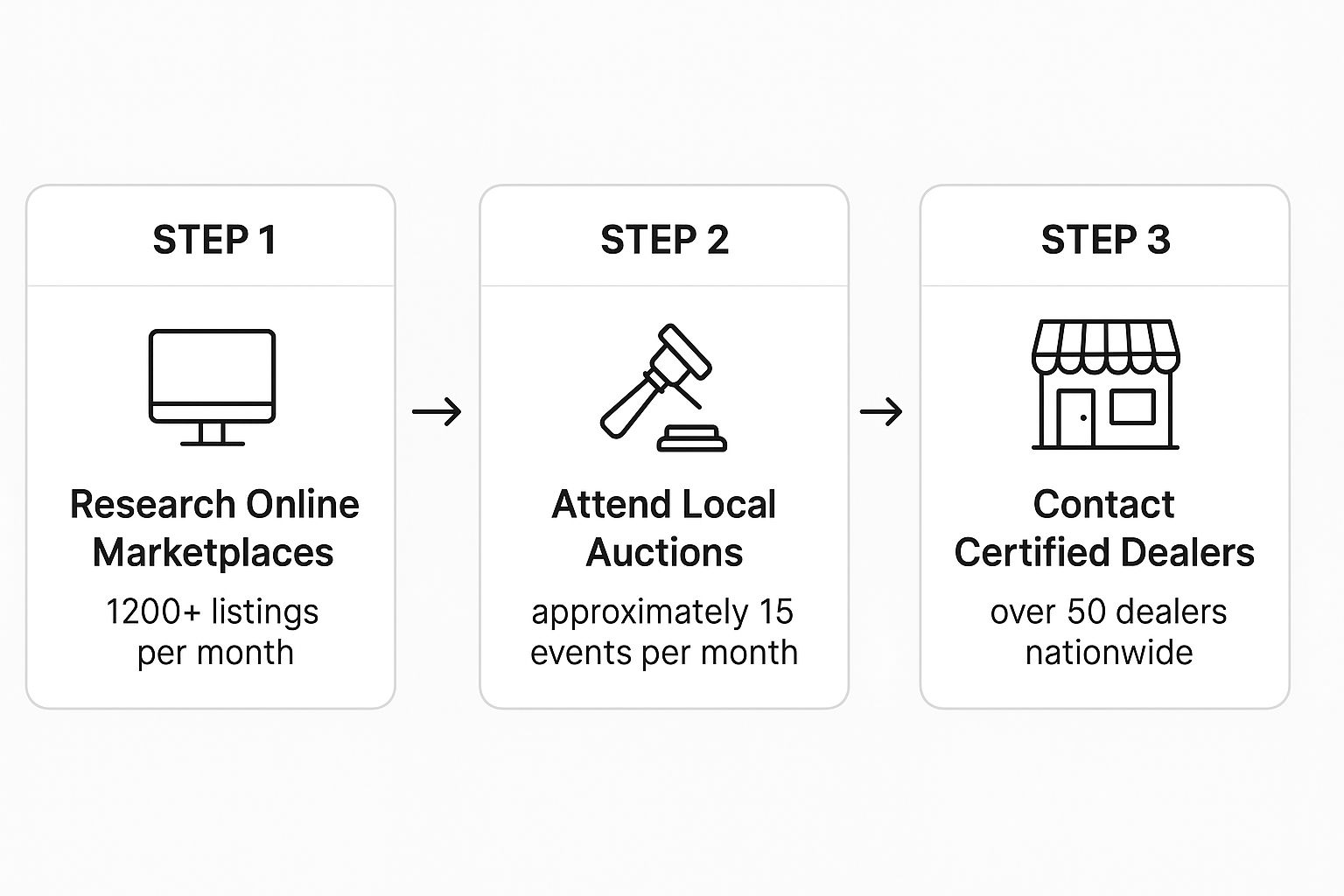

The infographic below gives you an idea of the different places you might find equipment before you even get to this inspection stage.

As you can see, while online marketplaces offer the most listings, going through a certified dealer provides a level of verification that is often worth the peace of mind.

To help you stay organized during an inspection, here’s a quick-reference table covering the essentials for the most common types of equipment.

Your Quick-Reference Inspection Checklist

| Equipment Type | Key Inspection Points | Red Flags to Watch For |

|---|---|---|

| Refrigeration | Check door gaskets for pliability. Listen to the compressor cycle. Inspect coils for cleanliness. Verify temperature holds steady. | Brittle/torn gaskets, loud/grinding compressor noises, dirty coils, significant temperature fluctuations. |

| Ovens | Test for even heating with a thermometer. Check for rust in the cavity. Inspect door hinges and seals. | Temperature variance >20°F, visible corrosion, wobbly doors, or a poor seal. |

| Gas Ranges | Inspect all gas lines and fittings. Test all burners for a strong, blue flame. Check oven ignition and pilot lights. | Gas smell when off, yellow/uneven flames, failure to ignite, cracked hoses. |

| Griddles/Fryers | Check for warped surfaces. Test heating elements/burners for even heat. Inspect drain valves and tanks for leaks or cracks. | Uneven heating (cold spots), sticky or leaky valves, visible cracks or rust in the fry pot. |

This checklist isn't exhaustive, but it covers the critical points that can save you from a bad purchase. Think of it as your first line of defense.

The Final Details You Can't Afford to Miss

Don't forget to check the small stuff. These details often tell a bigger story about how the equipment was treated. Wiggle the knobs, open and close all the doors repeatedly, and check the stability of the legs and shelves. Do the parts feel flimsy or solid? These quick tactile checks can reveal a lot about the unit's build quality and its history.

Finally, hunt for the data plate. This little metal tag has the model and serial number, which you’ll need to research the unit’s age, find manuals online, and source replacement parts. If that plate is missing or unreadable, servicing the equipment down the road becomes a whole lot harder.

This diligence is more than just kicking tires; it's a strategic investment of your time. The global market for used restaurant equipment is booming, with forecasts projecting growth to $15.7 billion at a CAGR of 5.8%. This trend is being driven by smart operators looking for budget-friendly, sustainable ways to grow. You can learn more about the sustained growth of this market and what it means for restaurateurs.

Ready to Buy? How to Negotiate the Best Deal

Finding that perfect used convection oven or reach-in cooler is a fantastic start, but your work isn't quite done. The real magic in saving money happens at the negotiation table. This is where you turn all that diligent inspection work into real, tangible savings that go straight to your bottom line.

Approaching a negotiation isn't about being aggressive or trying to win a battle; it's about being prepared. When you walk in armed with knowledge about the equipment's true condition and market value, you can have a confident, fair conversation with the seller. A successful negotiation is one where everyone walks away feeling good about the deal.

Use Your Inspection as Leverage

That detailed inspection you did? It wasn't just for your peace of mind—it’s your single most powerful negotiation tool. Every little flaw you spotted, from a slightly worn gasket on a fridge door to a cosmetic dent on a range, is a valid point for discussion. These are future costs or imperfections that should absolutely be reflected in the final price.

When you bring these points up, be specific and respectful. Instead of a vague "it's kind of old," try something like, "I noticed the door gasket is pretty brittle and will likely need to be replaced soon, which is about a $75 part." This approach shows you've done your homework and anchors your request for a discount in a real, quantifiable cost.

The goal isn't to nitpick every tiny scratch. It's to build a clear, logical case for a reasonable price adjustment based on the unit's actual condition. A seller who knows their equipment has a few quirks is often ready to be flexible if you can justify your position.

The market for kitchen gear is more competitive than ever. The number of U.S. food service establishments recently grew to over 711,000, a significant jump from earlier in the same year. This rising demand fuels the market for used equipment as savvy operators hunt for cost-effective solutions. You can discover more insights about this market growth and see how it's impacting what you might pay.

Anchor Your Offer with Market Research

Never, ever walk into a negotiation without a number in your head. Before making an offer, do your homework on the fair market value for that specific make and model. Check online marketplaces, see what similar units sold for at recent auctions, and look at listings from other dealers.

This research allows you to make an initial offer that is both reasonable and firm. You can open the conversation with something like, "Based on my research, similar models in this condition are selling for around $800. Considering the worn components I found, I can offer you $700." This immediately frames your offer as one based on data, not just a random lowball number.

Get Everything in Writing

Once you've verbally agreed on a price, it's time to make it official. This is arguably the most critical step in protecting yourself. Always insist on a formal bill of sale that details every single aspect of the transaction. A handshake deal just isn't enough when you're buying used restaurant equipment.

Your bill of sale should clearly state:

- Buyer and Seller Information: Full names and contact details.

- Equipment Details: The manufacturer, model number, and serial number.

- Final Price: The final agreed-upon sale amount.

- Condition: A statement confirming the unit is sold "as-is" or detailing any specific promises made.

- Included Accessories: A list of every single cord, shelf, pan rack, or attachment that comes with it.

This written record is your proof of purchase and ownership, and it prevents any "he said, she said" arguments later about what was included. If it's a significant purchase, exploring your payment options is a smart move. Our restaurant equipment financing guide can help you understand what's available.

Finally, knowing when to walk away is just as important as knowing how to negotiate. If a seller is unwilling to provide a detailed bill of sale or seems shady about any of these final steps, take that as a red flag. Trust your gut and be ready to move on. There will always be another deal.

Common Questions About Used Equipment

Diving into the world of used restaurant equipment can feel a bit like treasure hunting. Even when you’ve got a plan, a few questions always seem to pop up. Getting straight answers is the key to making a smart buy and avoiding those common slip-ups that can catch even seasoned pros off guard.

This is where we tackle those questions head-on. I’ll give you the direct, no-fluff answers you need to understand the used market, from figuring out risks to sniffing out hidden costs, so you can make your final decision with total confidence.

Should I Buy As-Is or Refurbished Equipment?

This is one of the biggest decisions you’ll make, and the right call really boils down to your budget, how much risk you're comfortable with, and your own technical skills. It's the classic trade-off: save money now or buy some peace of mind for later.

"As-is" equipment is, on paper, the cheapest way to go. You're buying the unit exactly as it is, history and all. This can work out great if you're a whiz at diagnosing problems and handling repairs yourself, or if you have a great technician you can call. Just remember, the risk is 100% yours.

Refurbished gear from a solid dealer, on the other hand, costs more upfront but cuts that risk way down. These pieces have been professionally checked over, cleaned, and serviced. Worn-out or broken parts have been replaced, and they usually come with a limited warranty. A 30- or 90-day guarantee can be an absolute lifesaver.

For the gear your business can't run without—I’m talking about your main cooking line or your entire refrigeration setup—spending a little extra on a refurbished unit is almost always the smarter, safer move. Think of the extra cost as an insurance policy against a breakdown right in the middle of a dinner rush.

What Are the Biggest Hidden Costs?

That price tag on a piece of used equipment? That’s just the starting line. I’ve seen plenty of folks score a great deal on a machine, only to watch their savings get eaten up by costs they didn't see coming.

Knowing about these potential expenses from the get-go is the only way to build a realistic budget. The three most common surprise costs are:

- Transportation: Commercial kitchen equipment is big and heavy. Unless you're buying locally and have a truck with a few strong buddies, you're going to be paying for freight shipping. Always get a shipping quote before you say yes to the deal.

- Installation: This one’s a biggie. Equipment that runs on gas or needs high-voltage wiring (like most commercial ovens and ranges) has to be installed by a certified pro. This is not a DIY project; it's about safety and staying on the right side of the law.

- Immediate Repairs: I always tell people to budget an extra 10-20% of the purchase price for little things the unit will need right away. This could be for new gaskets, a few replacement knobs, fresh filters, or other small parts needed to get it running perfectly.

Building these costs into your budget from the start will save you from some nasty financial surprises later on. For a good look at everything you might need, our complete restaurant equipment checklist is a great resource to have on hand.

Factoring in Shipping and Delivery

One of the biggest rookie mistakes I see is forgetting about shipping until the very last minute. That amazing deal you found on a six-burner range can quickly lose its shine when you get hit with a massive freight bill. Shipping rates for heavy-duty items like commercial freezers or prep tables aren't trivial; they depend on the item's weight, dimensions, and how far it has to travel. Before you even agree to a price, you need to have a firm shipping quote in hand. This isn't just a minor detail—it's a significant part of your total investment. When you're arranging delivery, think through the logistics on your end, too. Do you have a loading dock, or will you need a truck with a liftgate service? Who will be there to receive and move the equipment inside? For oversized items, you might need a more secure option like a Full Truckload (FTL) shipment to ensure it arrives safely. Factoring these delivery details and costs into your budget from the start is crucial for making sure your great deal on used equipment stays a great deal all the way to your kitchen door.

How Can I Find the Age of a Piece of Equipment?

Figuring out how old a used unit is plays a huge part in judging its remaining lifespan and what it's really worth. The first place to look is the manufacturer's data plate.

This little metal tag, usually on the back or side of the unit, has the model number and, most importantly, the serial number. You can often use the serial number to track down the manufacturing date with a quick search on the manufacturer's website or by giving their customer service a call.

And don't be shy about asking the seller for the unit's story. A good seller should be able to tell you:

- How it was used (a high-volume diner is a lot different than a quiet little cafe).

- How often it was serviced.

- If they have any maintenance records.

You can't always verify everything, but a seller who gives you clear answers and has some paperwork is a fantastic sign. If they get dodgy? That’s a red flag.

What Used Equipment Should I Avoid Buying?

While you can find amazing deals on most used gear, there are a couple of items where the risk just isn't worth the potential savings. It’s usually best to tread very carefully here.

First on the list: ice machines. These things have complicated internal systems that are a nightmare to inspect for hidden scale buildup, mold, or bacteria. A contaminated ice machine is a major health code violation just waiting to happen. For safety and peace of mind, it’s almost always smarter to lease or buy a new ice machine.

Second, be really wary of super specialized or digitally complex equipment. I'm talking about machines with proprietary software or unique circuit boards. If something goes wrong, finding a technician who knows how to fix it or getting your hands on replacement parts can be next to impossible. A tiny electronic glitch can turn your bargain into a very expensive doorstop.

Once you’ve made your purchases, you might need a place to keep them before installation day. For some great tips on how to store kitchen appliances safely, this guide is a big help.

At The Restaurant Warehouse, we get that outfitting your kitchen is one of the biggest investments you’ll make. We're here to help you do it smartly and affordably. Whether you need reliable new equipment with full warranties or are exploring our flexible financing and lease-to-own programs, our team is dedicated to supporting your success. Check out our extensive online catalog and see how we can help you build the kitchen you need to thrive.

Find your perfect equipment at https://therestaurantwarehouse.com.

Key Takeaways

- Get Better Gear for Less: Choosing used equipment is a strategic move that gives you access to higher-quality, more reliable brands that would normally be out of reach. This lowers your startup costs and frees up capital for other essential parts of your business, like marketing and staff.

- Let Your Menu Write Your Shopping List: Before you look at a single piece of equipment, finalize your menu. Create a "must-have" list based on what you'll actually be cooking to prevent overspending and ensure your kitchen workflow is efficient from day one.

- Inspect Everything, Negotiate with Confidence: A detailed, hands-on inspection is your most powerful tool. Identify any issues—from a worn-out gasket to uneven heating—and use those specific points to justify a lower price and secure a truly fair deal.

Related Articles

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment