Pre-Owned Perfection: Navigating the Used Prep Table Refrigerator Market

Why Smart Kitchens Choose Secondhand

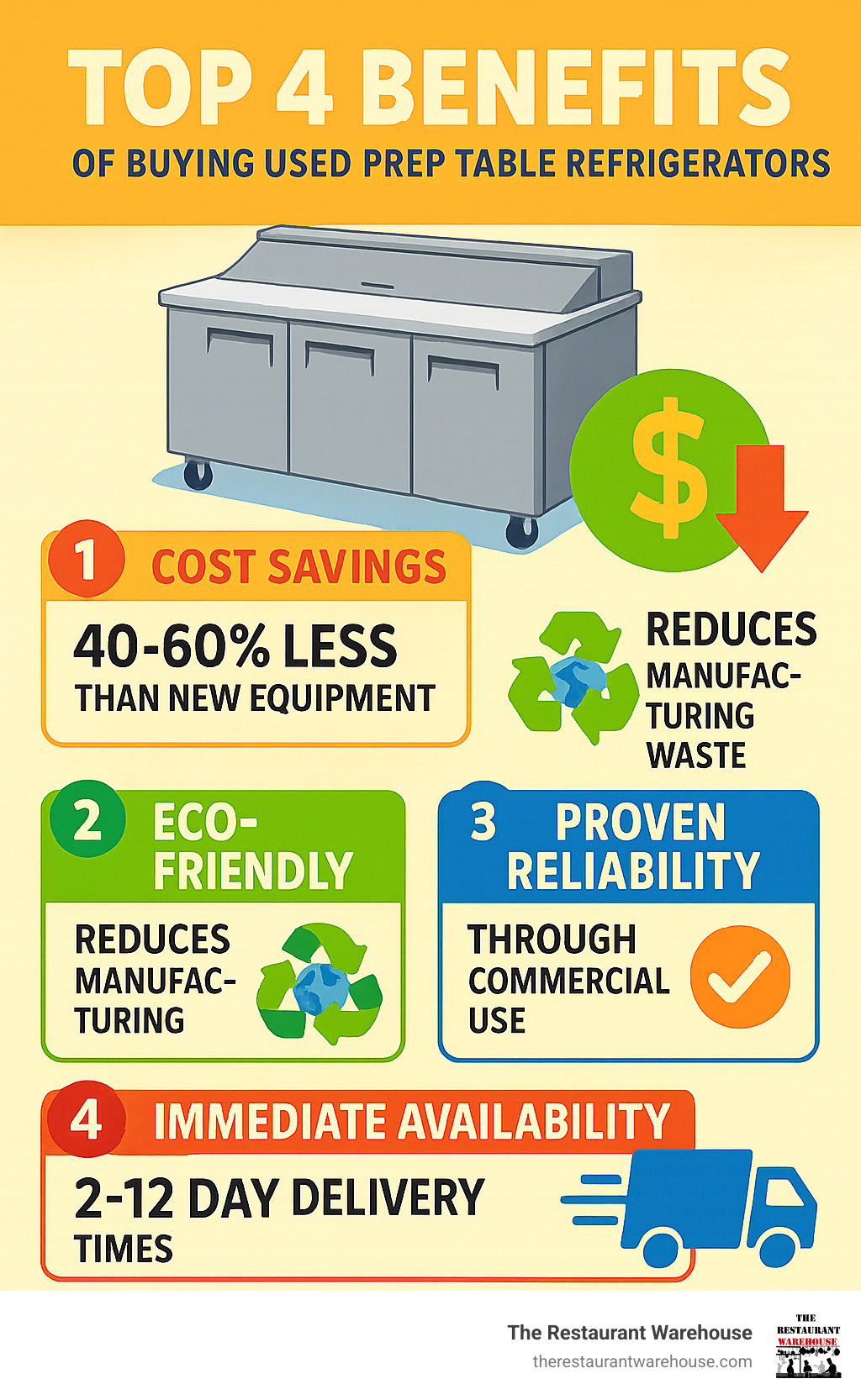

Finding a quality prep table refrigerator used can save your restaurant thousands while delivering the same performance as new equipment. Used prep tables typically cost 40-60% less than new, with many refurbished models offering 90-day warranties and professional cleaning.

Quick Guide to Buying Used Prep Table Refrigerators:

- Price Range: $800 - $4,500+ depending on size and condition

- Key Inspection Points: Test temperature control, check gaskets, examine stainless steel for damage

- Best Sources: Certified used equipment dealers, restaurant auctions

- Warranty: Look for 90-day parts and labor coverage on refurbished units

- Delivery: Usually 2-12 business days for in-stock items

The commercial kitchen equipment market has evolved, and restaurant owners no longer need to choose between quality and affordability. As one satisfied buyer noted about their used 27" prep table: "Tested and works well" - proving that secondhand doesn't mean second-rate.

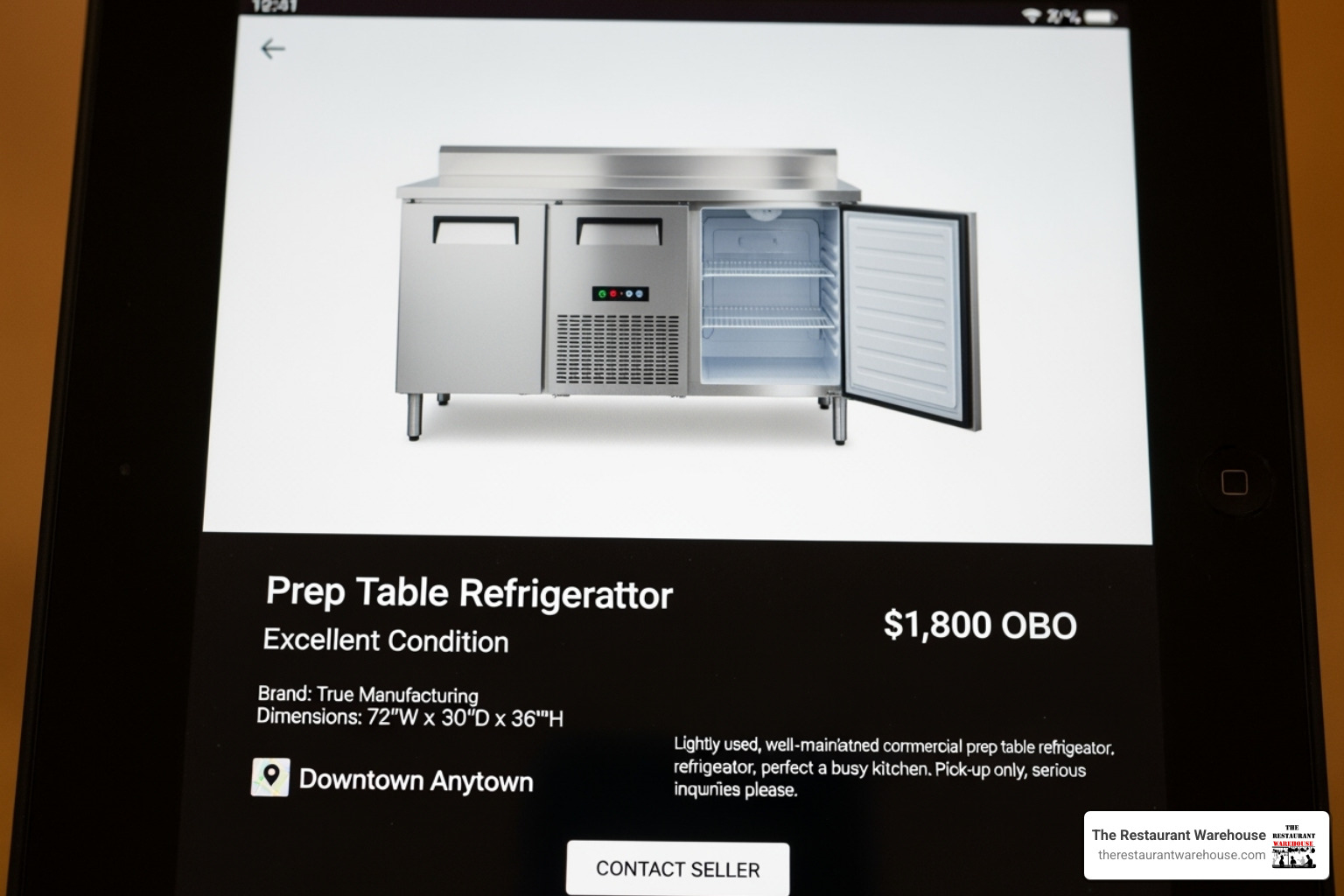

The math is simple. A new 48" sandwich prep table can cost over $3,000, while the same unit, professionally refurbished, might run $1,800. That's a $1,200 savings that can be reinvested into your business. Used equipment also means immediate availability, shipping quickly from in-stock inventory, unlike new units that may take weeks to arrive.

Choosing used also has a positive environmental impact, keeping functional refrigerators out of landfills and reducing manufacturing demand. However, buying used requires knowledge, as not all sellers are equal. A properly refurbished unit can run flawlessly for years, while a poorly maintained one can cause problems.

Decoding the Options: Types of Used Prep Table Refrigerators

When shopping for a prep table refrigerator used, understanding the different types is key to finding the right fit for your kitchen. Each style serves a specific purpose, from making sandwiches to prepping pizzas. The benefit of buying used is finding exactly what you need without the premium price tag.

Let's break down the main categories.

Sandwich and Salad Prep Tables

These are the workhorses of most commercial kitchens. A sandwich prep table combines refrigerated storage below with easy-access ingredient pans on top. This setup keeps everything from lettuce and tomatoes to meats and cheeses chilled and organized in one compact unit.

- Standard Top: These models have a streamlined design with a cutting board depth of 8 to 12 inches, ideal for smaller operations.

- Mega Top: These units offer expanded ingredient capacity, holding up to 18 pans in 1/6 or 1/9 size configurations. Their cutting boards are often deeper, around 15 inches, creating a larger workspace.

When inspecting used units, check the lift-up lids. They are essential for food safety and energy efficiency, keeping ingredients at the proper temperature and reducing energy costs. The refrigerated base storage can range from 6-8 cubic feet in smaller units to over 15 cubic feet in larger models.

Pizza Prep Tables

Pizza prep tables are specifically designed for dough handling and pizza assembly. Their standout feature is a raised rail design, which lifts ingredient pans above the work surface. This creates a deeper work surface below, which is crucial for stretching dough and maneuvering large pizza peels.

This design allows for accommodating large dough trays directly in the unit, streamlining workflow. Some used pizza prep tables feature granite or marble tops, which stay cool and prevent dough from sticking, making them a valuable find on the used market. The refrigerated ingredient wells are also configured for pizza-making efficiency.

Worktop and Undercounter Refrigerators

These units offer pure versatility. Without the specialized pan rails, their flat top workspace can be used for general prep, as a plating station, or to hold small equipment while keeping ingredients cold below.

- Doors vs. Drawers: The choice impacts workflow. Drawers excel at organization, allowing you to dedicate specific drawers to different ingredients. Door models typically offer more raw refrigerated base storage for larger items like hotel pans or bulk ingredients.

- Compact Footprint: Undercounter models are especially valuable in tight kitchens, as they can be placed under existing counters to add refrigerated storage without taking up floor space.

These units can significantly improve kitchen layout and workflow optimization. The best prep table refrigerator used is one that eliminates steps and keeps everything you need within arm's reach.

The Buyer's Checklist: Key Factors for Your Prep Table Refrigerator Used Purchase

Buying a prep table refrigerator used requires looking beyond the surface to ensure you're getting a reliable piece of equipment. You don't need to be a refrigeration expert, but knowing what to check can save you from a costly mistake.

Size, Capacity, and Layout

Before you buy, measure everything twice. Check your available floor space, but also doorways, hallways, and any tight corners. A unit that fits your kitchen but not your back door is a major problem.

- Width: This impacts your daily workflow. A 48-inch table holds about 12 ingredient pans, while a 72-inch model holds 18 or more. Choose based on your menu's needs.

- Height: Most prep tables are around 35 inches high, which works for most staff and is under the 36-inch maximum for ADA compliance. This ensures accessibility for all employees.

- Interior Cubic Feet: This determines your backup storage capacity. A small café might need 12 cubic feet, while a busy pizzeria could require 20+ cubic feet to minimize trips to the walk-in.

Visualize your busiest service period. Can staff work around the unit without creating bottlenecks? The right size is crucial for an efficient workflow.

The Heart of the Machine: Inspecting the Refrigeration System

A used prep table is only as good as its refrigeration system. Listen to the compressor; it should hum quietly and cycle on and off smoothly, not grind or rattle. The location of the compressor (front, side, or rear) affects maintenance access and ventilation requirements.

Temperature consistency is non-negotiable. The unit must hold a steady temperature between 33°F and 40°F, as per food safety temperature guidelines from the FDA. Check for oily residue around connections, which could indicate refrigerant leaks. Modern units often use eco-friendly R290 refrigerant, which has a lower environmental impact than older types like R134a. Also, consider temperature recovery time—how quickly the unit returns to a safe temperature after the doors have been opened.

Construction and Condition

The physical condition tells a story. 430-grade stainless steel is common for exteriors, while more corrosion-resistant 304-grade stainless steel is often used for interiors. Minor scratches are cosmetic, but deep gouges can harbor bacteria.

Door gaskets are critical. They should be pliable, not cracked or hard. A poor seal wastes energy and compromises food safety. Test every door and drawer; they should open smoothly and close securely. Wobbly hinges indicate wear. Finally, inspect the interior for rust and check that the cutting board is not warped or deeply cut.

Electrical and Placement Considerations

Before finalizing a purchase, check the unit's data plate for its electrical requirements. Most prep tables run on a standard 115V circuit, but you must confirm the amperage draw to ensure your outlet can handle the load without tripping breakers. Verify the plug type (e.g., NEMA 5-15P) matches your receptacle. Using an extension cord is strongly discouraged as it can be a fire hazard, cause voltage drops that damage the compressor, and may void any warranty. Proper placement is also vital for performance. The unit needs adequate ventilation, so check the manufacturer's specifications for required clearance—usually a few inches on the sides and back. Avoid placing the refrigerator directly next to heat sources like a range or fryer, as this will force the compressor to work harder, increasing energy consumption and shortening its lifespan.

Understanding the Fine Print: Warranty and Returns

This is where reputable sellers shine. Refurbished units have been professionally inspected, cleaned, and tested, with worn parts replaced. They cost more than "as-is" units but offer peace of mind. "As-is" units come with no guarantees and are risky unless you have repair expertise.

A 90-day warranty covering both parts and labor is a good standard to look for. Clarify any geographic limitations on service coverage. Understand the return policies, as some sales are final or involve restocking fees. The best sellers will allow you to test equipment before it leaves their showroom.

The Smart Shopper's Guide to Finding a Prep Table Refrigerator Used

Now that you know what to look for, the next step is finding a reliable source. Choosing the right seller for your prep table refrigerator used is as important as choosing the right unit.

Where to Find Reputable Sellers

A reputable seller stands behind their equipment and provides support.

- Used Equipment Specialists: These are your best bet. They have a reputation to uphold and follow a thorough refurbishment process. This includes sourcing quality equipment, conducting detailed inspections, replacing worn parts like compressors or gaskets, and testing each unit to ensure it runs reliably. Many have showrooms where you can inspect equipment in person.

- Online Suppliers: The best online sellers provide detailed descriptions, high-quality photos, and clear policies on warranties and returns. Check customer reviews to gauge their reliability and service.

- Restaurant Auctions: You can find great deals here, but it's risky. Equipment is sold "as-is" with no warranty. This option is best for experienced buyers who can quickly evaluate equipment.

- Local Dealers and Classifieds: This is the "wild west" of used equipment. You might find a gem or a lemon. Prices are attractive, but you're on your own for inspection, testing, and future repairs.

When evaluating a seller, ask about their refurbishment process and warranty. A 90-day parts-and-labor warranty shows confidence in the product.

The Pre-Purchase Inspection: Your Final Check for a prep table refrigerator used

Even with a reputable dealer, a final inspection is crucial. Think of it as your insurance policy.

- Plug In and Test: Let the unit run for at least 30 minutes to ensure it reaches the set temperature and to listen to the compressor.

- Check Temperature Drop: Use your own thermometer to verify the unit reaches the safe zone of 33-40°F.

- Inspect Gaskets: Use the paper test. Close the door on a piece of paper; if it pulls out easily, the seal is weak.

- Examine Door Hinges: They should be solid and allow doors to close firmly on their own.

- Listen to the Compressor: Note how often it cycles. Constant running can indicate an efficiency problem.

- Verify All Parts: Ensure all advertised shelves, pans, and rails are included.

Navigating Shipping and Delivery

Getting your prep table refrigerator used to your kitchen safely requires planning.

- Shipping Quote: Request this before you buy, as freight can add hundreds to the cost.

- Delivery Timelines: A major advantage of used equipment is faster delivery, often within 2-12 business days.

- Inspect for Shipping Damage: Before signing the delivery receipt, inspect the unit for any new dents or scratches and document them.

- Curbside vs. Inside Delivery: Curbside means you're responsible for getting it inside. For heavy units, inside delivery is usually worth the extra cost.

Life After Purchase: Maintenance and Common Issues

Congratulations on your prep table refrigerator used purchase. Now, the goal is to keep it running smoothly. Proper maintenance is key to longevity and protects your investment, ensures food safety, and prevents mid-service breakdowns.

A well-maintained used unit can easily outlast a neglected new one.

Essential Maintenance for Your Used Prep Table Refrigerator

Consistent, proactive care can add years to your equipment's life. Creating a simple maintenance log can help ensure these tasks are completed regularly.

- Daily Tasks: Wipe down door gaskets with a damp cloth to remove food debris. Clean any spills on the interior or exterior immediately. Check the thermometer to ensure it's holding the correct temperature.

- Weekly Tasks: Perform a more thorough cleaning of the unit's interior using a food-safe cleaner. Remove and clean shelves and pan supports. Check and clear the drain lines to prevent clogs and water buildup.

- Monthly Tasks: This is the most critical task: clean the condenser coils. Unplug the unit and use a stiff brush or vacuum to remove all dust and grease buildup. Clogged coils are the number one cause of compressor failure. Check that casters or legs are tight and level.

- Annual Tasks: Schedule a professional servicing. A qualified technician can check refrigerant levels, test electrical components, and perform a comprehensive inspection to catch small problems before they become major, costly repairs.

Troubleshooting Common Problems

Even with good maintenance, issues can arise. Here’s how to handle common ones.

- Temperature Fluctuations: Often caused by dirty condenser coils or poor airflow. Ensure there are several inches of clearance around the unit and that it's not near a heat source like an oven or fryer. Also, avoid overloading the cabinet with warm product, which forces the system to work too hard. Finally, check door gaskets for wear.

- Compressor Issues: If the compressor runs constantly, the first step is always to clean the condenser coils. If it won't start or makes grinding noises, turn the unit off and call a technician immediately.

- Water Leaks: Usually a drainage problem. Check if the drain pan is full or cracked, or if the drain line is clogged with debris.

- Worn-Out Gaskets: If you notice frost buildup, condensation on the exterior, or the unit runs more often, test the seal with the dollar bill test. Gasket replacement is an inexpensive, effective fix.

- Frost Buildup: In a refrigerator (not a freezer), this indicates an air leak. Check door seals and ensure doors are closing completely. High kitchen humidity or frequently leaving the door open can also contribute.

- Coil Leaks: Oily residue around refrigerant lines or a sudden stop in cooling are serious signs. Shut the unit down and call a professional. This is why buying from a dealer with a warranty is so important.

Know your limits. Simple cleaning is a DIY task, but anything involving refrigerant or electrical components requires a certified technician.

Frequently Asked Questions about Used Prep Tables

Buying a prep table refrigerator used is a significant investment, and it's natural to have questions. Here are answers to some of the most common ones we hear from restaurant owners.

What is the typical price range for a used prep table refrigerator?

The price for a prep table refrigerator used varies widely, from around $780 for an "as-is" unit to over $6,490 for a premium refurbished model. However, most buyers can find a quality unit in the $1,500 to $4,500 range.

Key price factors include:

- Size: A compact 27-inch unit will cost less than a large 70-inch model.

- Condition: A professionally refurbished unit with a warranty costs more upfront than a risky "as-is" unit but provides peace of mind.

- Age and Brand: Newer units from top-tier manufacturers command higher prices.

- Features: Mega tops, digital controls, or granite surfaces also add to the cost.

For most kitchens, investing in a professionally refurbished unit is the sweet spot between saving money and ensuring reliability.

How long should a well-maintained used prep table last?

A well-maintained prep table refrigerator used can be a workhorse in your kitchen for 5 to 10 years or even longer. Its lifespan depends heavily on a few factors.

- Maintenance: Regular cleaning of condenser coils and gaskets is crucial. Annual professional tune-ups can catch problems early.

- Brand Reputation: Some brands are known for their durability and are built to withstand the demands of a commercial kitchen.

- Initial Condition: A unit that was lightly used and well-cared-for in its previous life will have more years of service to give.

With proper care, your used prep table can be a long-term, reliable partner in your kitchen's success.

Is it better to choose a unit with doors or drawers?

This common question comes down to your kitchen's specific workflow and storage needs.

Doors are for bulk storage. They offer more cubic footage and flexibility for storing large containers, bags of ingredients, or stacks of prep pans. The downside is that items in the back can be harder to reach.

Drawers are for organization and efficiency. They allow staff to quickly access pre-portioned ingredients without bending or digging, which can speed up service. Each drawer can be dedicated to a specific food type, keeping things organized. The trade-off is less overall storage space and a higher initial cost.

Consider your menu and prep style. If your team is constantly grabbing small amounts of many different items, drawers are likely the better choice. If you deal more with bulk storage, doors offer more capacity for the price. Many modern units offer a combination of both, providing a versatile solution.

Conclusion: Your Next Step to a More Efficient Kitchen

Choosing a prep table refrigerator used is a smart business strategy that savvy restaurant owners use to improve their bottom line and kitchen efficiency. The benefits are clear and compelling.

You can save 40-60% off new prices, freeing up significant capital to invest in other areas of your business, like marketing or ingredients. This isn't a gamble on quality; reputable dealers offer professionally refurbished units that are backed by a 90-day warranty, ensuring reliable performance.

Commercial kitchen equipment is built to last, and a well-maintained used unit can provide another 5 to 10+ years of dependable service. By choosing used, you also make an environmentally responsible choice, keeping functional equipment out of landfills.

The used market offers incredible variety and immediate availability, so you can get the exact unit you need without waiting weeks for a new one to ship. You are now equipped with the knowledge to inspect gaskets, check the compressor, understand electrical requirements, and know the difference between stainless steel grades.

Simple maintenance, like cleaning condenser coils, will protect your investment for years. Empowering food service professionals with the knowledge to make smart purchasing decisions is key to a thriving industry.

When you're ready to take the next step, choosing a prep table refrigerator used is a strategic investment in your workflow, food safety, and long-term success. Your kitchen deserves equipment that works as hard as you do, and the used market delivers proven performance at prices that make sense.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment