Mixing It Up: Your Essential Guide to Commercial Food Mixers

Why Commercial Mixers Are the Backbone of Your Professional Kitchen

Commercial mixers are essential workhorses in any professional kitchen, bakery, or foodservice operation. Whether you're kneading dense pizza dough, whipping light meringues, or blending batters, these powerful machines transform time-consuming manual tasks into efficient, consistent processes.

Quick Answer: What Are Commercial Mixers?

Commercial mixers are heavy-duty food preparation machines designed for professional kitchens. Here's what sets them apart:

- Types: Planetary mixers (versatile, all-purpose), spiral mixers (specialized for dough), countertop models (space-saving), and floor models (high-volume)

- Capacity: Range from 5 quarts to over 140 quarts

- Power: High-horsepower motors with gear-driven transmissions

- Key Features: Multiple speed settings, safety guards, attachment hubs, and commercial-grade durability

Driven by the growing demand for automation and consistent food quality, the global commercial mixers market continues to expand. For restaurant owners and startup restaurateurs, investing in the right commercial mixer means increased productivity, consistent product quality, and reduced labor costs. But with so many types, sizes, and features available, choosing the right one can feel overwhelming.

This guide breaks down everything you need to know about commercial mixers—from understanding the difference between planetary and spiral models to calculating the right capacity for your operation. As commercial mixer specialists, we've spent years helping operators find the right models for their kitchens. Our goal is to help you make an informed decision that sets your kitchen up for long-term success.

Types of Commercial Mixers and Their Uses

When you're shopping for commercial mixers, you'll find that different models are designed for specific tasks. Just as you wouldn't use a paring knife to butcher a side of beef, you wouldn't use the same mixer for delicate whipped cream that you'd use for heavy pizza dough. Understanding the different types is your first step toward making a smart investment.

Planetary Mixers: The All-Purpose Workhorse

If you're looking for the Swiss Army knife of commercial mixers, the planetary mixer is it. The beater, whisk, or hook rotates on its own axis while simultaneously revolving around the inside of the bowl. This dual-action movement ensures every bit of your ingredients gets mixed thoroughly.

What makes planetary mixers so popular is their incredible versatility. They're equally comfortable kneading dense bread dough as they are whipping light, airy meringues. They can tackle everything from kneading dough for artisan breads to whipping cream, egg whites, and mashed potatoes. They're perfect for blending batters for pancakes and cakes, and they make quick work of frostings and icings.

This versatility makes planetary mixers ideal for restaurants, bakeries, and catering operations that need one reliable machine for multiple tasks. The real beauty is in the attachments—swap out the flat beater for a wire whip or dough hook, and you've transformed your mixer for an entirely different job. If you want to explore more about these versatile machines, check out our detailed guide on Planetary Mixers.

Practical scenarios where planetary mixers shine include:

- Multi-station restaurants that need a single mixer to handle pastry, sauce prep, and dough.

- Catering teams that value quick changeovers between batters and whipped components.

- Commissary kitchens producing standardized recipes across multiple sites.

Spiral Mixers: The Dough Specialist

While planetary mixers are fantastic generalists, sometimes you need a specialist. If your operation revolves around producing large quantities of dough—especially the heavy, stiff kind used for artisan breads, pizza, and bagels—then a spiral mixer is your best friend. In a spiral mixer, the bowl itself rotates while a stationary spiral-shaped hook does the kneading. This creates a gentle, consistent kneading action that develops gluten beautifully without overheating your dough. High-volume bakeries and pizzerias swear by spiral mixers because they can handle enormous batches of dough while maintaining a perfect, consistent texture.

Consider spiral mixers when:

- Your menu is dough-centric (pizza, bagels, bakery items) and batch sizes are large.

- You need cooler dough temperatures and minimal oxidation for optimal crumb and fermentation.

- You value repeatable gluten development over multitasking.

Countertop vs. Floor Models

Beyond the mixing action, commercial mixers come in two basic formats: countertop and floor models. The right choice depends on your kitchen's space and production volume.

Countertop mixers are the space-savers, sitting right on your workbench. They typically handle capacities from 5 to 20 quarts, which is plenty for many restaurants, cafes, and smaller bakeries. They give you professional power without requiring dedicated floor space.

Floor mixers are the heavyweights. These free-standing units are built for serious production, with capacities ranging from 30 quarts to 140 quarts or more. The extra size isn't just about capacity; floor models provide greater stability and power for mixing dense, heavy batches. If you're operating a busy bakery or a large catering operation, a floor model is likely what you need.

At The Restaurant Warehouse, we understand that choosing between these options can be overwhelming. Contact us and we'll guide you through the selection process based on your actual kitchen needs and budget. Or, if you prefer a deep dive on models and specs, browse our mixer lineup here: Commercial Mixers Collection.

How to Choose the Right Commercial Mixer for Your Business

Picking the right commercial mixer is about matching the right machine to your actual needs, your budget, and your business's future. Think of it like hiring a new team member: you need to know they can handle the workload during your busiest shifts and grow with you.

Capacity and Batch Size

The capacity of commercial mixers is measured in quarts (Qt), ranging from compact 5-quart models to massive 140-quart floor units. A common mistake is buying too small and wasting time splitting batches, or buying too large and wasting space and money.

Start by calculating your needs during peak production. Your busiest day, not your average one, should guide your decision. Also, consider the Absorption Ratio (AR), which is the ratio of water to flour by weight. A stiff dough with a low AR is much harder on a mixer than a wet dough with a high AR.

A simple planning example for a pizza operation:

- Goal: 180 14-inch pizzas on Friday (peak day)

- Dough ball: 14 oz; total dough required approximately 158 lbs

- If your mixer's rated dough capacity is 50 lbs at 60% AR, you'll need about 3-4 batches with production buffer

General rules of thumb:

- The rated capacity is not always the practical capacity for your recipe

- High-fat or high-sugar doughs behave differently

- If you're consistently at 80-90% of capacity, consider sizing up

Always size for your peak demand and consider future growth. For a detailed look at how different sizes compare, take a look at our 8 Quart Mixer Comparison guide.

Power, Motor, and Drive System

If capacity is about how much you can mix, power is about how well you can mix it. The motor and drive system are the heart and muscle of any commercial mixer.

- Horsepower (HP): Higher horsepower helps power through tough doughs and large batches without stalling

- Torque and gear train: Commercial units use all-metal gears for consistent torque under load

- Direct drive vs belt drive: Direct or gear-driven designs minimize slippage and maintenance

- Speed control: Variable speeds (often 3 or more) allow gentle incorporation to start, then higher speeds for development

- Duty cycle: Look for continuous-duty ratings if your mixer will run back-to-back batches

Electrical considerations:

- Smaller mixers typically run on 120V

- Larger floor models may require 208-240V single-phase or three-phase

- Check plug type and circuit requirements before purchase

Key Features and Safety Standards

Modern commercial mixers come with features essential for safety, efficiency, and health code compliance.

- Bowl guards are mandatory safety features that prevent hands or utensils from entering the bowl during operation

- An emergency stop button should be prominent and easy to reach

- Overload protection automatically shuts the mixer down if the motor is strained

- Digital timers and programmable settings ensure consistency across batches

- For larger floor models, power bowl lifts reduce physical strain when handling heavy bowls

- NSF and ETL certifications indicate the equipment meets rigorous public health and safety standards. Learn more about what these certifications mean from authoritative sources like NSF International

When you're ready to explore mixers that balance these essential features with your budget, contact us for expert guidance. We're here to make sure you get a mixer that works as hard as you do.

Maximizing Your Investment: The Benefits and Care of Commercial Mixers

When you invest in a high-quality commercial mixer, you're making a strategic decision that will impact your kitchen's efficiency, product quality, and bottom line. With proper care, these workhorses will become indispensable members of your team.

The Core Benefits for Your Professional Kitchen

A commercial mixer does more than just mix ingredients; its impact is substantial.

- These machines streamline food preparation. Tasks that once required significant manual labor now happen in a fraction of the time

- They deliver consistent product quality. Commercial mixers eliminate batch-to-batch variations with precise speed controls

- They reduce labor costs. When prep time drops, you can redirect staff to higher-value activities

- They enable menu expansion. Artisan breads, pastries, or other items that seemed too labor-intensive become feasible

- They handle dense ingredients. Stiff doughs and other tough mixtures are no problem for gear-driven systems

ROI snapshot:

- Fewer, larger batches minimize changeover time and reduce labor hours

- Programmable timers improve repeatability, cutting waste and remakes

- Ergonomic features can reduce workplace injuries and related costs

Essential Maintenance for Your Commercial Mixers

Even the best commercial mixer requires proper care. A solid maintenance routine will protect your investment and ensure it serves you reliably for years.

Daily tasks (end of shift):

- Clean and sanitize the bowl, agitators, bowl guard, and all food-contact surfaces

- Wipe exterior surfaces, paying attention to vent areas to prevent dust and flour buildup

- Inspect the area below the mixer for spills or flour accumulation

Weekly tasks:

- Check agitators, bowl locks, and attachment hubs for wear or misalignment

- Verify that safety interlocks engage properly

- Inspect the power cord for nicks or compression damage

Monthly/quarterly tasks:

- Review the manufacturer's lubrication schedule

- Inspect gear trains or belts for wear, noise, or play

- Confirm mounting stability to prevent vibration

Troubleshooting cues:

- Unusual noise under load can indicate bearing or gear wear

- Overheating may signal overcapacity batches or inadequate ventilation

- Inconsistent speed can indicate control issues or impending motor problems

Follow Manufacturer Guidelines: Your mixer's user manual is the definitive guide to keeping your specific model in peak condition.

If you need expert guidance on maintaining your specific mixer, contact us, and our team can walk you through maintenance schedules and troubleshooting tips.

Understanding Attachments and Accessories

One of the most exciting aspects of owning a commercial mixer is its versatility through various attachments and accessories.

Most commercial planetary mixers arrive with three essential attachments. The dough hook is for kneading heavy doughs for bread and pizza. The flat beater (or paddle) is a general-purpose tool for cake batters, cookie doughs, and icings. The wire whip excels at aerating ingredients, like whipping cream or egg whites.

Many commercial mixers also feature an attachment hub, a standardized power take-off port. This hub allows your mixer's motor to power various mixing-related accessories, turning it into a multi-functional workstation. For example, a bowl scraper attachment can be added to continuously scrape the bowl sides during mixing.

Optimization tips:

- Label attachments and store them within reach of the workstation

- Pre-scale ingredients during off-peak hours and use timer functions

- Create recipe cards that specify attachment type, speed, and time

Ready to streamline prep and consistency? Explore our lineup and pricing at wholesale rates: Shop Commercial Mixers.

Navigating the Market: Pricing, Warranties, and Innovations

The commercial mixer market can feel overwhelming, but understanding what drives pricing, what warranties cover, and which innovations matter will help you steer it with confidence.

Typical Price Ranges for Commercial Mixers

The cost of a commercial mixer varies based on format, capacity, power, and build quality.

- Countertop models (5-20 Qt): Entry point for restaurants, cafes, and pastry stations that need professional performance in a compact footprint

- Mid-capacity floor models (30-60 Qt): Ideal for busy bakeries and commissaries with stronger motors and reinforced frames

- Large-capacity floor models (80-140+ Qt): Built for high-volume operations with continuous duty cycles

What drives price:

- Brand engineering and support: Proven reliability, parts availability, and training resources

- Power and drive system: Higher HP and gear-driven transmissions cost more but last longer

- Construction: Heavy-duty frames, all-metal gears, and stainless bowls increase durability

- Controls and features: Digital timers, programmable cycles, and power bowl lifts add value

Total cost of ownership factors:

- Downtime and parts availability

- Energy use under load

- Training and ergonomics

For budget-conscious operators, we invite you to explore our full range of mixers where you'll find wholesale pricing without the retail markup.

Warranty and Support Options

A warranty is your insurance policy. When investing in a commercial mixer, understanding what's covered is crucial. Most come with a manufacturer warranty covering parts and labor for a specific period, often one year.

The commercial use clause is critical. Residential mixer warranties are voided in commercial settings. Ensure your mixer's warranty explicitly covers professional use. Also, consider replacement parts availability and customer support quality.

Smart support planning:

- Keep a small inventory of high-wear items on hand

- Document your serial numbers, install dates, and service contacts

- Train at least two team members on daily checks and basic troubleshooting

If you have specific warranty questions or want help comparing coverage, Get a Quote and talk to our team today.

Latest Trends and Innovations

The commercial mixer industry is constantly evolving with new features that make these machines more efficient, safer, and easier to use.

- Smart timing and programmability: Timers and saveable programs help standardize results across shifts

- Efficiency gains: Motors delivering higher torque at lower amperage can cut heat and power draw

- Improved safety: Improved guard designs, more responsive e-stops, and robust interlocks

- Ergonomics and hygiene: Power bowl lifts, smooth external surfaces, and sealed controls

Looking to future-proof your purchase? We can help you compare models side-by-side and align features to your recipes and growth plans. Book a Strategy Call: https://therestaurantwarehouse.com/pages/contact-us.

Frequently Asked Questions

After years of helping foodservice operators choose the right commercial mixers, we've heard just about every question imaginable. Here are the most common inquiries we receive about commercial mixers.

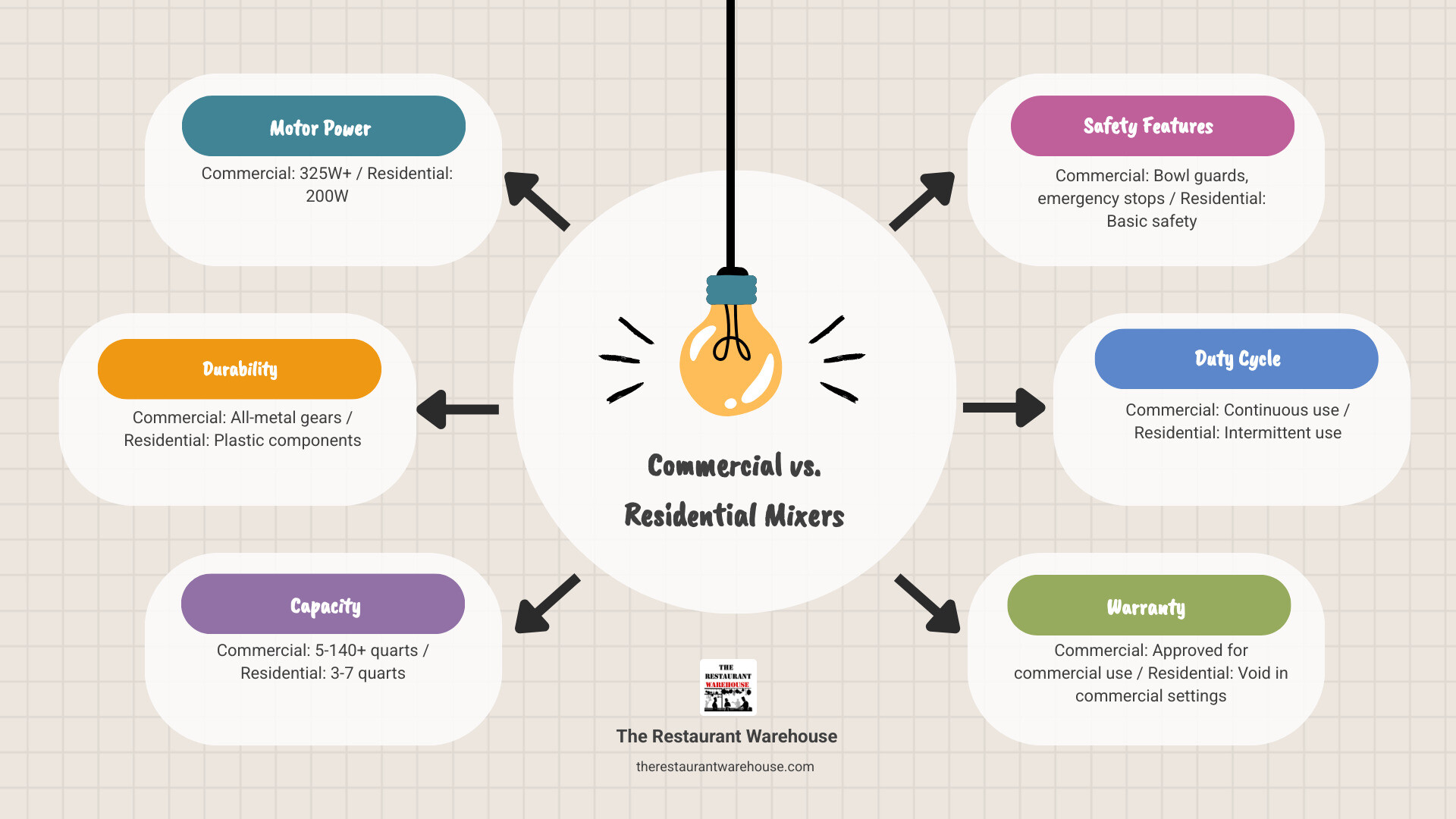

How do commercial mixers differ from residential models?

The differences between commercial mixers and their residential counterparts are fundamental. It's not just about size; it's about durability, power, and safety.

- Durability: Commercial mixers are built for continuous, heavy-duty use with robust metal components. Residential models often use plastic parts and are not designed to run for hours on end.

- Power and Transmission: Commercial models use powerful, high-torque motors and all-metal, gear-driven transmissions. This allows them to handle dense doughs without straining. Residential mixers use less powerful motors and often have belt drives that can slip or break under commercial stress.

- Capacity: Commercial mixers range from 5 quarts to over 140 quarts, while residential models typically max out around 7 or 8 quarts.

- Safety: Commercial mixers are equipped with mandatory safety features like bowl guards and emergency stop buttons, which are absent on residential models.

- Warranty: A commercial mixer's warranty covers its use in a professional kitchen. Using a residential mixer for business purposes will void its warranty.

Bottom line: A commercial mixer is an industrial tool, while a residential mixer is a home appliance. Using the wrong one for the job can lead to costly breakdowns and safety hazards.

What does the "Absorption Ratio" (AR) mean for a mixer?

The Absorption Ratio (AR) is a crucial term if you work with dough. It refers to the ratio of water to flour by weight in a recipe. For example, a recipe with 100 pounds of flour and 60 pounds of water has a 60% AR.

This matters because the AR indicates how stiff your dough is. A low-AR dough (stiffer) puts much more strain on a mixer's motor and gears than a high-AR dough (wetter) of the same weight. Manufacturers provide maximum dough capacities based on a specific AR (e.g., "50 lbs at 50% AR"). Exceeding these limits can cause motor strain and damage. Understanding AR helps you correctly size your commercial mixer to ensure it can handle your specific recipes without being overworked.

What is an attachment hub and why is it important?

An attachment hub is a feature on many planetary commercial mixers that dramatically increases their versatility. It's a standardized power take-off port, often located on the front of the mixer's head, that allows you to connect various accessories.

Think of the attachment hub as a universal connection point that lets other tools tap into your mixer's powerful motor. This transforms your mixer into a multi-function workstation, saving you from buying separate, single-purpose appliances. This capability maximizes your equipment's return on investment by allowing one robust machine to perform multiple tasks. It saves money, counter space, and simplifies maintenance. For example, you can use specialized mixing tools like a bowl scraper to improve efficiency.

If you're ready to explore how a versatile commercial mixer can transform your kitchen's productivity, contact our team for personalized guidance on selecting the right model and attachments for your specific operation.

How do I calculate the right size mixer for my menu?

Start with your heaviest recipe and your busiest shift:

- Determine batch weight and AR.

- Check the manufacturer's capacity chart for dough and batter limits.

- Estimate batches per hour and total batches for peak day.

- Add a 10–20% growth buffer. If you make both delicate and dense products, consider a planetary mixer with multiple attachments or pair a planetary with a spiral for dough-heavy menus. For tailored recommendations, visit our collection and compare models: Commercial Mixers.

Do I need a floor model or will a countertop unit work?

Choose based on batch size, throughput, and ergonomics. Countertop mixers (5–20 Qt) suit pastry stations, cafes, and light dough work. Floor models (30–140+ Qt) provide the power and stability needed for frequent heavy dough production. If you regularly split batches with a countertop mixer, a floor model may pay for itself by reducing labor and changeovers.

How important are timers and programmable controls?

Very. Timers and saveable programs reduce variability across shifts, help avoid overmixing, and free staff for other tasks. If your menu includes multiple standardized recipes, programmable steps can protect quality and speed training.

Can a planetary mixer handle dough as well as a spiral mixer?

Planetary mixers can handle dough within their rated limits, especially with a dough hook and proper AR. However, for large, frequent dough batches—particularly low-AR bread or pizza dough—a spiral mixer will knead more gently and efficiently, maintain cooler dough temperatures, and improve gluten development.

What about cleaning and sanitation best practices?

Disassemble bowls, guards, and attachments, then wash, rinse, and sanitize following your local regulations. Avoid high-pressure spraying near control panels. Dry completely before reassembly to prevent microbial growth and protect motors and controls. Wipe the mixer body daily to prevent flour, sugar, and grease buildup.

How loud are commercial mixers?

Noise varies by model, capacity, and load. Gear-driven mixers under heavy load will be audible but should not grind or screech. Unusual or increasing noise is a warning sign—schedule inspection to prevent a larger failure.

Can I convert voltage later?

Some models offer field-convertible voltage kits, but many do not. Select the correct voltage at purchase, and coordinate with your electrician for the proper receptacle and breaker. Planning this early saves time and cost later.

How long should a mixer last?

With proper sizing, routine maintenance, and trained use, commercial mixers can perform reliably for many years. Heavy-duty, gear-driven models delivering frequent dense dough batches are designed for this kind of long-term service.

Have more questions or want a side-by-side comparison tailored to your recipes? Contact Us: https://therestaurantwarehouse.com/pages/contact-us.

Conclusion

Choosing the right commercial mixer is a critical investment in your kitchen's efficiency, consistency, and future growth. It's a decision that pays dividends in productivity and product quality for years to come.

Remember these key takeaways:

- Planetary mixers offer versatility, while spiral mixers are specialists for high-volume dough production.

- Always match the mixer's capacity, power, and safety features to your specific operational needs.

- Proper maintenance and the right attachments extend your mixer's lifespan and open up its full potential.

At The Restaurant Warehouse, we believe every business deserves access to high-quality, affordable commercial mixers. Our commitment to wholesale pricing ensures you get the best value without compromising on performance. We're here to help you steer the options and find the perfect commercial mixer that fits your budget and lifts your culinary operations.

Explore our full range of mixers today and find the perfect fit for your kitchen's needs: Shop Commercial Mixers. If you'd like expert help with sizing, features, and budgeting, Book a Strategy Call with our team: https://therestaurantwarehouse.com/pages/contact-us.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment