Marble Top Pizza Prep Tables: Elevate Your Pizza Game

Why Marble Top Pizza Prep Tables Are Taking Over Professional Kitchens

In the , high-temperature world of a professional pizzeria, success is measured in consistency, speed, and quality. Every element of the kitchen must be optimized for peak performance, and nowhere is this more critical than at the prep station where the pizza-making process begins. For decades, chefs made do with simple wooden or stainless steel surfaces, but a piece of equipment has emerged as the undisputed champion for modern pizza artisans: the marble top pizza prep table. This specialized workstation masterfully combines the timeless, natural cooling properties of stone with the precision of modern refrigeration technology, creating the ultimate pizza-making command center.

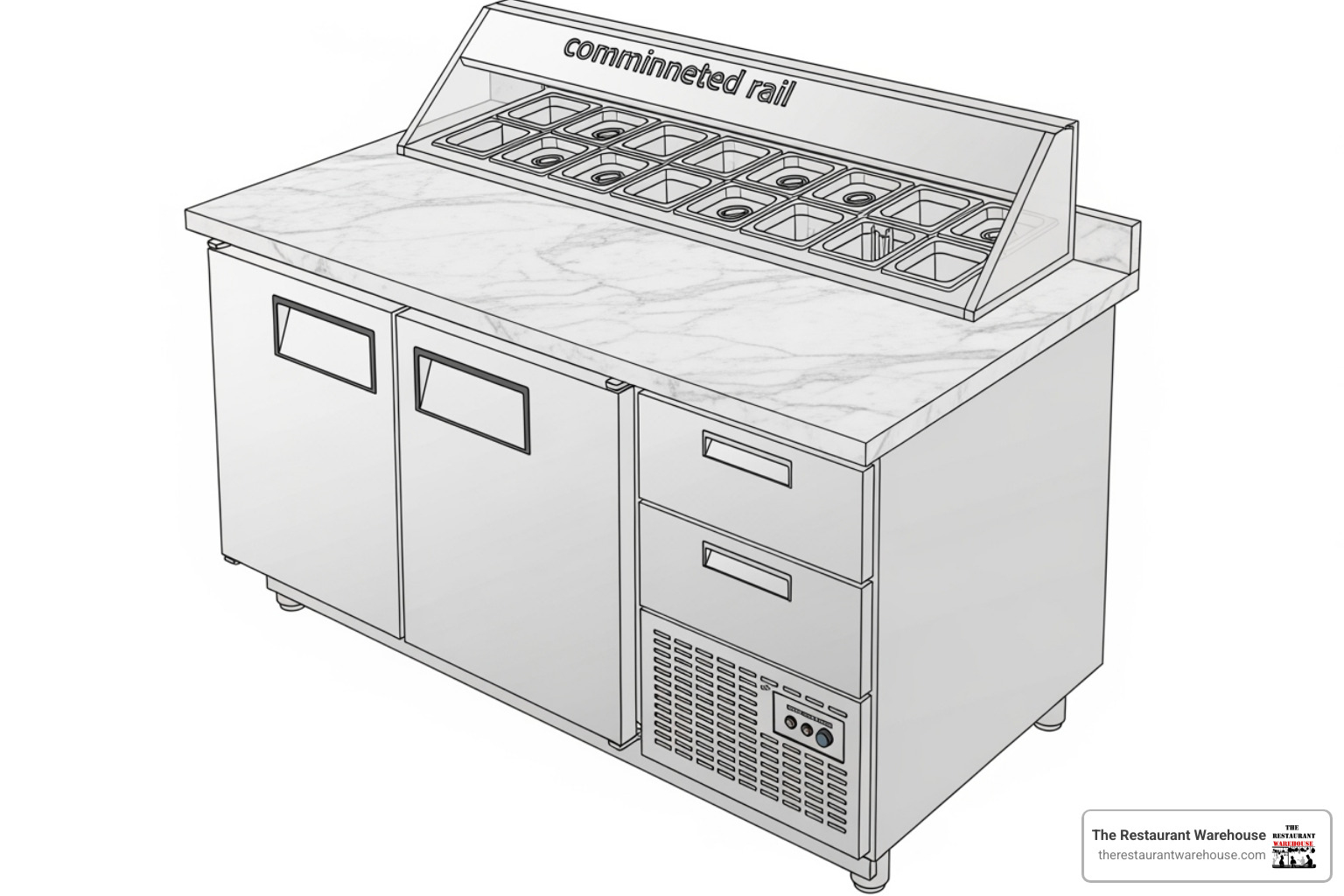

A marble top pizza prep table is an integrated system featuring a thick marble work surface mounted on a refrigerated base, complete with built-in, chilled storage for toppings. It is carefully designed to address the unique challenges of high-volume pizza operations, where controlling dough temperature and streamlining workflow are paramount.

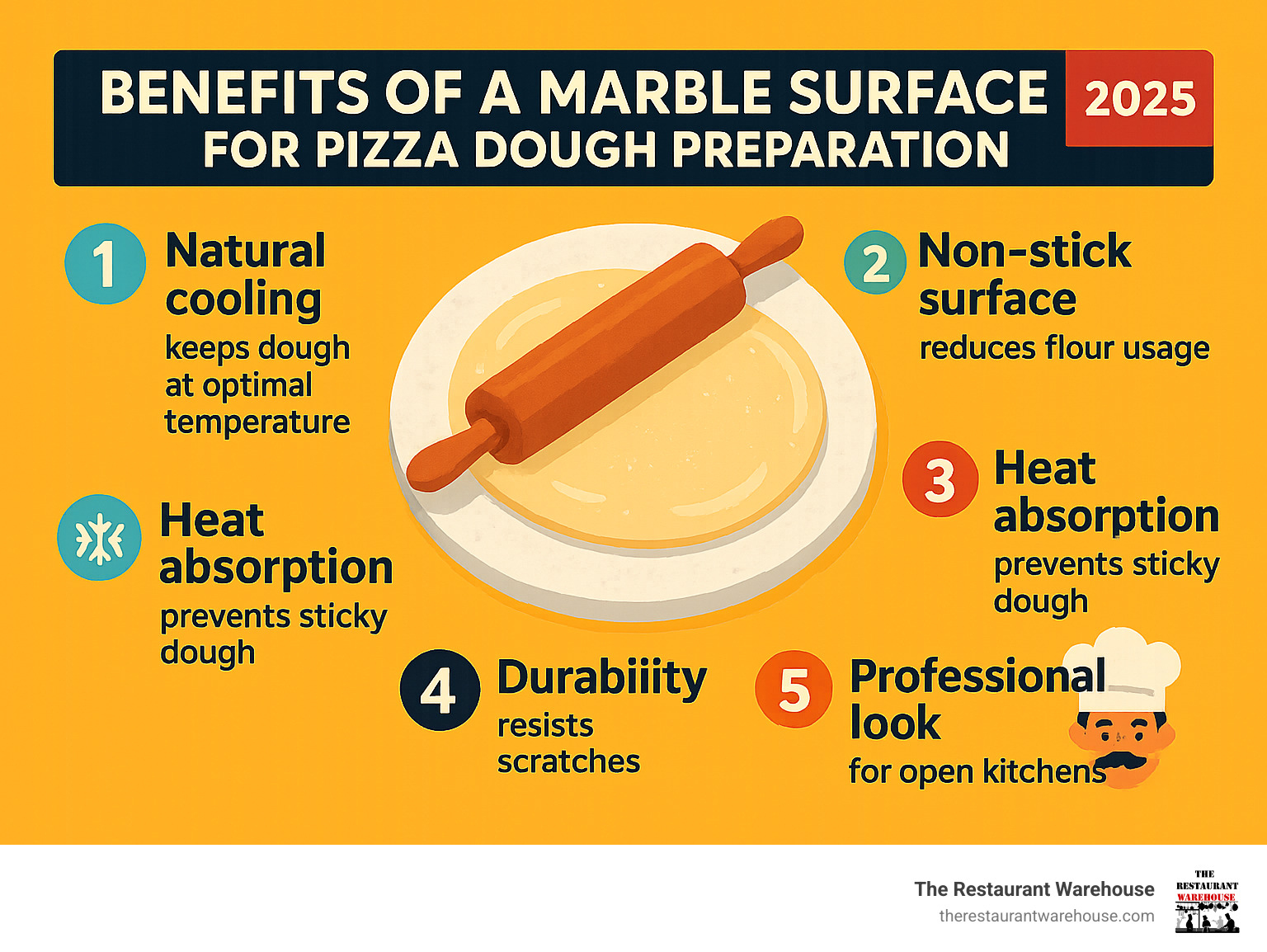

Key Features of Marble Top Pizza Prep Tables and Their Benefits:

- Natural Cooling Surface: Marble possesses a high thermal mass, allowing it to absorb heat and remain significantly cooler than ambient temperature. Unlike stainless steel, which quickly warms up, marble provides a consistently cool surface that prevents pizza dough from becoming sticky and difficult to handle. This leads to easier stretching, less reliance on dusting flour, and a superior final crust.

- Integrated Refrigeration: The refrigerated base keeps bulk ingredients like dough balls, cheese, and sauces at optimal, food-safe temperatures (typically between 32-42°F). This eliminates the need for constant trips to a separate walk-in cooler, keeping everything the chef needs within arm's reach and dramatically improving efficiency.

- Condiment Rail System: A refrigerated topping rail, or pan rail, is positioned above the work surface, holding numerous compartments for toppings. This setup allows for a highly organized mise en place, enabling chefs to assemble pizzas rapidly and accurately without cross-contamination.

- Durable and Hygienic Construction: The body of these tables is typically constructed from high-grade AISI 304 stainless steel, which is renowned for its durability, corrosion resistance, and ease of cleaning. The refrigerated cabinet is insulated with high-density, CFC-free polyurethane foam, ensuring temperature stability and energy efficiency.

- Versatile Sizing and Configurations: To fit the unique layout and volume demands of any kitchen, these tables are available in various sizes. Common widths include 60", 72", and nearly 80", with options for two or three doors, or even drawers, to customize storage.

When a pizzeria needs to stretch hundreds of dough balls during a hectic dinner rush, the work surface can be the difference between a smooth service and a chaotic one. While some traditionalists may argue for other surfaces, the overwhelming consensus among high-volume professionals is clear. As one industry veteran noted, the debate often centers on maintenance versus performance. However, for those who prioritize the quality of their dough, marble's superior handling properties are non-negotiable. The science is straightforward: marble acts as a heat sink, drawing warmth from the chef's hands and the dough itself. This maintains the dough's gluten structure at the perfect temperature for stretching, resulting in less flour usage, easier handling, and a remarkably consistent product, pizza after pizza.

Why a Marble Top is the Professional's Choice for Pizza Making

Step into any high-volume, quality-focused pizzeria, and your eyes will inevitably be drawn to the heart of the operation: the prep line. There, you'll likely see the cool, neat gleam of a marble surface where chefs transform simple dough balls into culinary masterpieces. The prevalence of marble top pizza prep tables in professional kitchens is no accident or mere aesthetic choice; it's a strategic decision rooted in food science, efficiency, and the pursuit of the perfect crust.

The secret to marble's superiority lies in its inherent physical properties. Unlike stainless steel, which has high thermal conductivity and quickly adapts to the ambient temperature of a hot kitchen, marble has a high thermal mass and lower conductivity. This means it acts as a natural heat sink, remaining cool to the touch even as the kitchen heats up. This single characteristic is a game-changer when working with delicate, temperature-sensitive pizza dough. The cool surface keeps the fats in the dough solid and the gluten relaxed but firm, making it pliable and easy to stretch without becoming a sticky, unmanageable mess. This translates to a cleaner, more efficient process, requiring significantly less dusting flour. The result is a superior crust with a perfect texture, free from the bitter taste of scorched flour on the bottom.

Beyond its thermal advantages, marble is a remarkably durable material well-suited to the rigors of a commercial kitchen. When properly cared for, it resists scratches from typical prep work and can withstand the temperature shocks of a busy environment. In the increasingly popular open-kitchen concept, a polished marble top conveys a sense of craftsmanship, tradition, and quality to discerning customers. Furthermore, when treated with a food-grade sealant, the naturally porous stone becomes a non-porous, hygienic surface that is easy to clean and sanitize, meeting stringent commercial food safety standards.

Keeping it Cool: The Science Behind Marble and Dough

To truly appreciate why marble is the ideal surface for pizza dough, it helps to understand the science. Marble's high thermal mass means it can absorb a significant amount of heat energy before its own temperature rises. When you place a ball of dough and your warm hands on the surface, the marble immediately begins to draw heat away, keeping the dough within its optimal working temperature range. This consistent temperature control is crucial for several reasons:

- Gluten Structure: It keeps the gluten network in the dough firm and elastic, allowing you to stretch it thinner and more evenly without tearing.

- Prevents Premature Fermentation: Overly warm dough can begin to ferment too quickly, leading to an undesirable sour taste and a dense, difficult-to-work-with texture. A cool surface slows this process down.

- Reduces Stickiness: Cooler dough is inherently less sticky. This is the primary reason chefs working on marble use far less dusting flour. This not only saves on ingredient costs over time but, more importantly, prevents excess flour from accumulating on the bottom of the pizza, which can scorch and impart a bitter flavor during the baking process.

Durability, Hygiene, and Alternative Stones

The longevity and safety of a marble surface in a commercial setting hinge on one critical factor: proper sealing. Raw marble is a metamorphic rock with a porous structure. A high-quality, food-grade sealant penetrates the stone and fills these microscopic pores, creating an impermeable barrier. This sealed surface is impressively scratch-resistant against the daily wear and tear of pizza prep (though cutting directly on the surface is never recommended) and prevents liquids and bacteria from being absorbed. Cleaning becomes simple: a pH-neutral cleaner and water, followed by a food-safe sanitizer, is all that's required. Acidic substances should be wiped away immediately to protect the sealant.

While marble is the classic choice, other stones like granite are also used. Granite is an igneous rock, generally harder and less porous than marble, making it slightly more resistant to scratching and staining. However, marble is often preferred for its superior thermal properties—it tends to stay cooler longer. Both are excellent choices, with the decision often coming down to aesthetic preference and specific kitchen needs. The prep tables themselves are built for the long haul, with robust AISI 304 stainless steel bodies and coved interior corners that eliminate crevices where food debris can accumulate. With a routine of daily cleaning, prompt spill management, and periodic re-sealing (typically every 6-12 months), a marble prep surface will serve as a reliable and beautiful foundation for your craft for many years.

Anatomy of a Marble Top Pizza Prep Table

A marble top pizza prep table is far more than a simple table with a stone slab; it is a highly sophisticated and integrated piece of kitchen engineering. Every component is purposefully designed and placed to create a seamless, ergonomic, and efficient workflow for the pizza chef. Understanding the anatomy of this essential equipment reveals why it is such a powerful tool in a professional kitchen.

The main components include:

- The Work Surface: The centerpiece is the thick, polished stone top, most commonly marble but sometimes granite. This surface provides the essential cooling properties for dough handling and offers a generous workspace. Standard depths are around 30 inches, with widths ranging from 60 to nearly 80 inches, providing ample room to prep multiple pizzas simultaneously. Many models include a raised rear backsplash to prevent ingredients from falling behind the unit.

- Refrigerated Base: Directly beneath the stone top lies a powerful refrigerated base, constructed from durable, corrosion-resistant AISI 304 stainless steel. This base contains the main storage compartments, the compressor, and the cooling system, forming the functional backbone of the unit.

- High-Density Insulation: The walls and doors of the refrigerated cabinet are injected with high-density, CFC-free polyurethane foam, typically 50mm (2 inches) thick. This insulation is critical for maintaining consistent internal temperatures, ensuring food safety, and enhancing energy efficiency by preventing cold air from escaping.

- Topping Rail System: An integrated, refrigerated topping rail (or condiment rail) sits at the back of the work surface. It is designed to hold multiple food pans (often up to 20) filled with toppings, keeping them chilled and within immediate reach. This transforms the table into a self-contained pizza assembly station.

- Customizable Storage Configuration: The refrigerated base is available in various configurations to suit different operational needs. Two-door and three-door models are common, with some units offering the option of drawers instead of doors. These compartments are sized to hold bulk ingredients, dough trays, and even full-size 18" x 26" sheet pans.

This all-in-one design allows a chef to pull chilled dough from the base, stretch it on the cool marble, top it with ingredients from the rail, and send it on its way—all within a few square feet. This consolidation of tasks makes it an indispensable asset for any serious pizzeria.

The Work Surface: More Than Just a Pretty Stone

The choice of stone is critical. While classic white and grey veined marble (like Carrara) is the iconic choice, known for its exceptional cooling, granite offers a harder, more speckled alternative that is slightly less porous. For high-volume pizza prep, both materials provide the necessary thermal performance. The work surface itself is designed for efficiency. A depth of up to 30 inches gives chefs plenty of real estate to work without feeling cramped. Common widths of 60", 72", or 79.7" are chosen based on the kitchen's output and available space. Features that seem minor, like a raised rear edge (backsplash) and ergonomic side panels, play a major role in containing flour and ingredients, keeping the workspace cleaner and more organized.

Integrated Refrigeration: The Key to Freshness and Efficiency

The refrigeration system is the unsung hero of the prep table. Its design directly impacts food quality, safety, and operational costs. Storage capacity scales with the unit's size, ranging from approximately 13.1 cubic feet in a 60-inch model to over 20.5 cubic feet in larger versions. These systems are engineered to maintain precise and distinct temperature zones. The main cabinet typically holds a temperature between 32°F and 40°F, ideal for storing dough and bulk items. The topping rail is often kept slightly warmer, between 35°F and 46°F, using a static cooling system to keep delicate toppings like fresh vegetables chilled without drying them out from excessive airflow. In contrast, the main cabinet uses a ventilated (forced-air) system to ensure even and rapid cooling. Modern units are packed with energy-efficient features, including self-closing doors with magnetic gaskets to ensure a perfect seal, eco-friendly R290 refrigerant, and robust yet efficient 1/4 HP compressors, all working together to deliver reliable performance while minimizing electricity consumption.

Key Specifications to Consider Before You Buy

Investing in a marble top pizza prep table is a significant decision that will shape your kitchen's daily workflow and product quality for years to come. To make an informed choice, you must look beyond the surface and dig into the key specifications. Focusing on the right size, capacity, refrigeration technology, and energy efficiency will ensure your new table is a powerful asset rather than a daily frustration. It is also crucial to verify safety and sanitation certifications, which guarantee the equipment meets strict industry standards for commercial use.

Here's a more detailed comparison of key specifications for popular sizes to guide your decision-making process:

| Size (Width) | Dimensions (Approx. W x D x H) | Capacity (Cubic Ft.) | Temp Range (Fahrenheit) | Compressor HP | Refrigerant Type | Electrical (V/Hz/Ph) | Net Weight (Approx. lbs) |

|---|---|---|---|---|---|---|---|

| 60" | 60" x 30" x 40" | 13.1 | 32-40°F (Base) | 1/4 HP | R290 | 110V/60Hz/1Ph | 480 |

| 72" | 72" x 39.5" x 38.5" | 18.0 (Est.) | 32-40°F (Base) | 1/4 HP | R290 or R404a | 110V/60Hz/1Ph | 550 (Est.) |

| 79.7" | 79.7" x 31.5" x 39" | 20.5 | 35-42°F (Base) | 1/4 HP | R290 | 110V/60Hz/1Ph | 632.4 |

Note: Specifications such as dimensions, capacity, and weight can vary slightly between manufacturers and specific models. Always consult the official product spec sheet before making a final purchase.

Finding high-quality equipment at affordable, wholesale pricing can be a challenge, but it allows you to procure the perfect marble top pizza prep table without the significant overhead of typical retail markups, stretching your budget further.

Sizing Up Your Space: Finding the Perfect Fit

Choosing the right size is a critical first step that involves more than just measuring the available floor space. You must consider the entire operational footprint of the unit. Common widths range from 60 inches for smaller pizzerias to nearly 80 inches for high-volume operations. When measuring, account for the total depth, which can approach 40 inches when including the condiment rail and allowing for space at the rear for ventilation. The work surface itself is typically 21-30 inches deep, so visualize your chefs working there. Will they have enough room to stretch dough comfortably? Also, plan for adequate clearance around the unit—at least 3-4 inches at the back and sides for airflow to the condenser, and enough space in front for doors to swing open fully without obstructing kitchen traffic. The choice between a two-door and a three-door model should be based on your projected volume and storage needs. A three-door unit provides substantially more refrigerated capacity, making it ideal for kitchens that go through large quantities of ingredients daily.

Understanding the Technical Specs of a Marble Top Pizza Prep Table

The technical specifications on a product sheet provide a wealth of information about the unit's performance, efficiency, and long-term reliability. Here's what to look for:

- Refrigerant: The type of refrigerant is a key indicator of modern, efficient design. R290 (propane) is the current industry standard for eco-friendly refrigeration. It has a very low Global Warming Potential (GWP) of 3, compared to older refrigerants like R404a (GWP of 3922). R290 is also more thermodynamically efficient, leading to lower energy consumption.

- Compressor: Most prep tables in this category use a 1/4 HP compressor. This size is carefully selected to provide sufficient cooling power without being oversized, which would lead to inefficient energy use through frequent cycling. The location of the compressor (side-mounted or rear-mounted) can also be a factor, affecting maintenance access and airflow requirements.

- Electrical: The majority of these units are designed to run on a standard 110V/115V electrical circuit and come with a standard NEMA 5-15P plug. This allows them to be plugged into a normal commercial outlet. However, it's always wise to check the amperage draw of the unit and confirm that your kitchen's electrical circuit can handle the load without tripping breakers.

- Weight: The substantial net weight of these tables (ranging from 480 to over 630 lbs) is a positive sign, indicating robust construction with heavy-gauge stainless steel and a thick stone top. This weight ensures the table remains stable and stationary during vigorous use. However, it also means you must plan carefully for delivery and installation, ensuring doorways are wide enough and that you have the necessary manpower or equipment to move it into place.

Maintenance and Care for Your Prep Station

Your marble top pizza prep table is a significant investment and a central pillar of your kitchen's productivity. To protect this investment and ensure it performs at its best for years to come, a consistent and thorough maintenance routine is essential. Proper care is relatively simple but pays huge dividends by extending the life of the equipment, ensuring it remains hygienic and food-safe, and preventing costly emergency repairs. A disciplined approach to daily cleaning, periodic deep cleaning, and regular attention to the refrigeration system will keep your station in prime, reliable condition.

Daily Cleaning and Long-Term Care for the Marble Top

The marble surface, while durable, requires a different and gentler approach than stainless steel. Following these steps will preserve its integrity and appearance:

- Use pH-Neutral Cleaners: This is the most important rule. Standard kitchen degreasers and acidic or abrasive cleaners (including vinegar, lemon juice, or scouring powders) can etch the surface, dulling its finish and compromising the sealant. Use cleaners specifically formulated for natural stone or a simple solution of warm water and a few drops of mild, pH-neutral dish soap.

- Wipe Spills Immediately: Marble's biggest vulnerability is its reaction to acidic substances. Ingredients like tomato sauce, citrus juices, vinegar, and wine can chemically etch the surface if left to sit, leaving a permanent dull spot. Train your staff to wipe up these spills instantly.

- Gentle Daily Wiping: After every shift, clean the entire surface with a soft, non-abrasive cloth or sponge to remove all flour, food debris, and oils. Follow up by drying it with a clean, dry microfiber cloth to prevent water spots and streaks.

- Periodic Re-Sealing: Because marble is naturally porous, it relies on a food-grade sealant to create a protective, non-porous barrier against stains and bacteria. In a busy commercial kitchen, this sealant will wear down over time. Plan to re-seal the surface every 6 to 12 months. The process is simple: thoroughly clean and dry the surface, apply the sealant according to the manufacturer's instructions, let it penetrate, and wipe away the excess.

- Always Use Cutting Boards: Never chop, slice, or dice directly on the marble. While a sealed surface is scratch-resistant, sharp knives can still cause deep scratches or chips that are difficult to repair.

Maintaining the Refrigeration Unit: A Preventative Schedule

The refrigeration system works hard to keep your ingredients safe. Proactive maintenance is key to its longevity and efficiency.

- Daily Checks: At the end of each day, wipe down the interior of the cabinet and the topping rail. Check the digital temperature displays to ensure they are within the correct range (Cabinet: 32-40°F, Rail: 35-42°F). Any significant deviation warrants further investigation.

- Weekly Tasks: Inspect the door gaskets (the rubber seals). Look for any cracks, tears, or areas where they are pulling away from the door. A poor seal is a major cause of energy waste and can cause the compressor to overwork. Clean the gaskets with warm, soapy water to remove grease and debris.

- Monthly Tasks: The condenser coil is the radiator of your refrigeration system, and it needs to be clean to dissipate heat effectively. Once a month, unplug the unit and use a stiff brush and a vacuum to remove all dust, grease, and debris from the condenser coils. Clogged coils are the number one cause of compressor failure.

- Quarterly Tasks: Check the condensate drain line to ensure it is clear and draining properly. Most units have an automatic defrost cycle, and a clogged drain can cause water to back up into the unit or leak onto the floor. If your unit has an accessible evaporator fan, check to ensure it is clean and spinning freely.

Following this simple schedule is one of the most effective ways to maximize the lifespan and performance of your marble top pizza prep table.

Frequently Asked Questions about Marble Top Pizza Prep Tables

Choosing the right marble top pizza prep table involves careful consideration of many factors. To help you make a confident and informed decision for your pizzeria, here are detailed answers to some of the most common questions.

How does a marble top pizza prep table differ from a stainless steel one?

The primary difference lies in the material of the work surface, which has a profound impact on performance, aesthetics, and maintenance.

- Temperature & Dough Handling: This is the key distinction. Marble has a high thermal mass, keeping it naturally cool. This prevents dough from sticking, requiring less flour and making it easier to stretch. Stainless steel has high thermal conductivity, meaning it quickly warms to room temperature, which can make dough sticky and difficult to work with, especially in a hot kitchen.

- Aesthetics & Ambiance: Marble offers a classic, artisanal, and high-end look. In an open kitchen, it signals quality and tradition to customers. Stainless steel provides a clean, modern, and industrial aesthetic that is functional and sleek.

- Maintenance & Durability: Stainless steel is non-porous, highly resistant to stains and acids, and requires very little maintenance. Marble is naturally porous and must be sealed with a food-grade sealant to prevent staining and bacterial absorption. It requires more careful cleaning (using pH-neutral cleaners) and periodic re-sealing (every 6-12 months). Acidic spills must be cleaned immediately to prevent etching.

- Cost: Generally, marble top prep tables carry a higher initial cost than their all-stainless-steel counterparts due to the price of quarrying, cutting, and finishing the stone.

What certifications are important for a commercial pizza prep table?

Certifications are non-negotiable in a commercial setting. They are your assurance that the equipment is safe, sanitary, and efficient. Look for these three key marks:

- ETL or UL Listed: These are Nationally Recognized Testing Laboratories. A UL or ETL mark indicates that the unit has been rigorously tested and meets North American standards for electrical safety and fire risk. This is essential for passing inspections and for insurance purposes.

- ETL Sanitation or NSF: This certification (often appearing as "ETL Sanitation Listed" or carrying the NSF logo) verifies that the equipment is designed and constructed for easy cleaning and sanitization. It means materials are non-toxic, surfaces are smooth, and there are no crevices where bacteria can hide, ensuring food safety.

- DOE (Department of Energy): This certification confirms that the refrigeration system meets or exceeds federal minimum energy efficiency standards. A DOE-certified unit will consume less electricity, saving you significant money on utility bills over its lifespan.

Is granite a better choice than marble for a pizza prep table?

Granite is a common and excellent alternative to marble. The choice often comes down to specific priorities:

- Hardness: Granite is an igneous rock and is significantly harder and denser than marble (a metamorphic rock). This makes it more resistant to scratching and chipping.

- Porosity: Granite is less porous than marble, making it naturally more resistant to staining. However, both stones require sealing in a commercial food prep environment.

- Thermal Properties: Both stones stay cool, but many chefs find that marble has a slight edge, feeling cooler to the touch and drawing heat from dough more effectively.

- Appearance: Marble is known for its soft, creamy appearance with distinctive, fluid veining. Granite has a more granular, speckled, or crystalline look. The choice is largely aesthetic.

What is the difference between a pizza prep table and a sandwich/salad prep table?

While they look similar, they are designed for different tasks. The key differences are:

- Work Surface: Pizza prep tables have a deep work surface (often 20+ inches) made of stone (marble/granite) to provide a large, cool area for stretching dough. Sandwich/salad prep tables have a much narrower work surface that is essentially a full-length poly cutting board, designed for slicing and assembling, not rolling dough.

- Topping Rail: Pizza tables often have straight-sided rails to accommodate round pizza pans. Sandwich tables may have angled rails for better visibility of ingredients.

Can I use a marble prep table for other food prep besides pizza?

Absolutely. The properties that make it ideal for pizza dough also make it a versatile station for other culinary applications. The cool, smooth surface is perfect for:

- Baking and Pastry: It's exceptional for working with butter-rich doughs like croissants, pie crusts, and puff pastry, as the marble prevents the butter from melting and making the dough greasy.

- Chocolate and Candy Making: The cool surface is perfect for tempering chocolate and for cooling and working with candies like fudge, caramel, or taffy.

- Cold Food Prep: It's an excellent surface for assembling charcuterie boards, cold appetizers, or delicate salads, especially with the convenience of the integrated refrigeration below.

Conclusion

In the competitive landscape of the modern food industry, the pursuit of excellence comes down to the details. It's clear that a marble top pizza prep table is not merely a piece of furniture, but a strategic investment in the core tenets of a successful pizza operation: quality, consistency, and efficiency. The unique, natural cooling properties of marble provide an unparalleled surface for handling dough, a fundamental step that directly influences the texture, taste, and quality of the final crust. This is where a good pizza becomes a great one.

By seamlessly integrating a durable, cool marble work surface with a high-performance, precisely controlled refrigerated base, these tables are engineered to optimize the entire pizza-making workflow. Ingredients remain perfectly chilled and carefully organized in the refrigerated cabinet and topping rail, empowering your culinary team to work with greater speed, accuracy, and less stress, even during the most demanding service periods. Constructed with robust AISI 304 stainless steel and designed with hygiene and maintenance in mind, a quality prep table is a long-term partner in your kitchen's success.

Equipping your kitchen with professional-grade tools is about empowering your staff to perform at their best and to produce a product that sets you apart from the competition. A marble top pizza prep table is a perfect embodiment of this principle, a testament to how the right equipment can lift craft into art.

When you are ready to take your pizza game to the next level, investing in a prep table designed specifically for the task is one of the most impactful decisions you can make. We encourage you to explore the full range of options available and find the perfect fit that will help you build the kitchen of your dreams and delight your customers for years to come.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment