Freshness on Demand: Top Commercial Prep Fridge Options

Introduction: Streamlining Your Kitchen Workflow

A commercial prep fridge is the unsung hero of any high-performing food service business, seamlessly combining refrigerated storage with a convenient, dedicated work surface. It functions as the central command station for assembling sandwiches, salads, pizzas, and appetizers, offering a suite of clear advantages that directly impact both efficiency and profitability.

- Keeps Ingredients Fresh: Maintains consistent, food-safe temperatures for every component, from crisp lettuce to cured meats.

- Boosts Efficiency: Places all necessary ingredients at your fingertips, eliminating wasted motion and dramatically reducing preparation time.

- Improves Workflow: Creates a logical, streamlined assembly line that speeds up order fulfillment and increases kitchen output.

- Improves Food Safety: Keeps perishable items within the correct temperature range throughout the prep process, ensuring full compliance with health codes.

Investing in the right prep fridge is not just about buying a piece of equipment; it's about optimizing your entire kitchen operation. A well-chosen unit supports a smooth, uninterrupted flow, guarantees food safety, and directly contributes to your bottom line by minimizing food waste and enabling faster customer service. These units are productivity powerhouses, carefully designed to keep your kitchen running at peak efficiency and your customers delighted with fresh, quickly prepared food.

This comprehensive guide will walk you through everything you need to know. We'll explore why these units are a game-changer, decode the different types available, help you choose the perfect model with the right features, and provide essential maintenance tips to maximize your investment.

Quick commercial prep fridge definitions:

Why a Commercial Prep Fridge is a Kitchen Game-Changer

A commercial prep fridge can be the difference between chaos and choreography during a lunch rush. It transforms kitchen operations by combining refrigerated storage with an immediate work surface, acting as a multitasking hub for assembling everything from sandwiches to pizzas. The commercial refrigeration market is projected to grow to $55.7 billion by 2030, reflecting how essential these units are for modern food service.

A prep fridge is a game-changer because it directly addresses the most critical kitchen challenges: operational efficiency, food safety standards, and HACCP compliance. When a cook has every ingredient perfectly chilled and within arm's reach, orders are fulfilled faster, the food is fresher, and staff avoid the time-consuming and hazardous practice of running between separate refrigerators and workstations. This consolidation leads to reduced food waste, as ingredients are visible, organized, and properly chilled. The immediate results are faster service times and a dramatically improved workflow. Over the long term, this translates to consistent product quality, as every dish is prepared with the same efficiency and freshness, building customer trust and loyalty. Find more about NSF food safety standards to understand the rigorous testing these units undergo.

The Core Functions of a Commercial Prep Fridge

A commercial prep fridge is indispensable due to its multiple, integrated roles that no other single piece of equipment can fulfill:

- Refrigerated storage: It offers a dual-zone cooling system. Specialized compartments in the top rail hold food pans with frequently used ingredients, while the cabinet below provides bulk storage for backup supplies.

- Work surface integration: The built-in cutting board is strategically placed at an ergonomic height (typically 36 inches), promoting a comfortable working posture that reduces strain during long shifts.

- Ingredient accessibility: By design, everything is within the cook's immediate sphere of work. This allows for the development of muscle memory, enabling staff to assemble complex orders with speed and precision, especially during peak hours.

- Temperature consistency: These units are engineered to maintain a steady 33°F to 41°F, the ideal range for food safety. Advanced digital controls allow for precise adjustments and monitoring, ensuring compliance and quality.

- Food preservation: The controlled, refrigerated environment preserves the texture, color, and flavor of delicate ingredients like fresh herbs, sliced vegetables, and proteins, significantly reducing spoilage and improving the final taste of the dish.

Boosting Kitchen Efficiency and Ensuring Food Safety

A commercial prep fridge creates consolidated workstations, turning cooks into efficiency experts. Staff can assemble entire menu items from one spot, saving significant time and motion during high-volume periods. This intelligent design offers several key benefits:

- Reduced cross-contamination risk: Designated wells, often with insulated lids and dividers, keep ingredients like raw meats and fresh vegetables physically separate, a cornerstone of safe food handling.

- Maintaining the cold chain: Ingredients remain in a refrigerated environment from storage to assembly, eliminating the dangerous temperature fluctuations that occur when using separate prep tables and refrigerators. This is a critical control point (CCP) in any HACCP plan.

- Ergonomic design benefits: The integrated layout minimizes bending, reaching, and twisting, which reduces staff fatigue and the risk of musculoskeletal injuries. A comfortable, less-stressed staff is proven to be more focused, efficient, and less prone to errors.

- Streamlined assembly: The entire layout is optimized for the linear process of building sandwiches, salads, and pizzas. This ensures a smooth, fast assembly that maintains both quality and safety, changing the entire kitchen's rhythm and allowing teams to handle higher order volumes without sacrificing standards.

Decoding the Options: Types of Prep Fridges and Key Features

Choosing a commercial prep fridge can seem daunting with so many options available. However, each type is engineered for specific culinary operations, and understanding their differences is key to optimizing your kitchen's workflow. Whether you're running a busy deli, a high-volume pizzeria, or a custom salad bar, there's a prep fridge designed to match your exact needs. Let's break down the options to help you find the perfect fit.

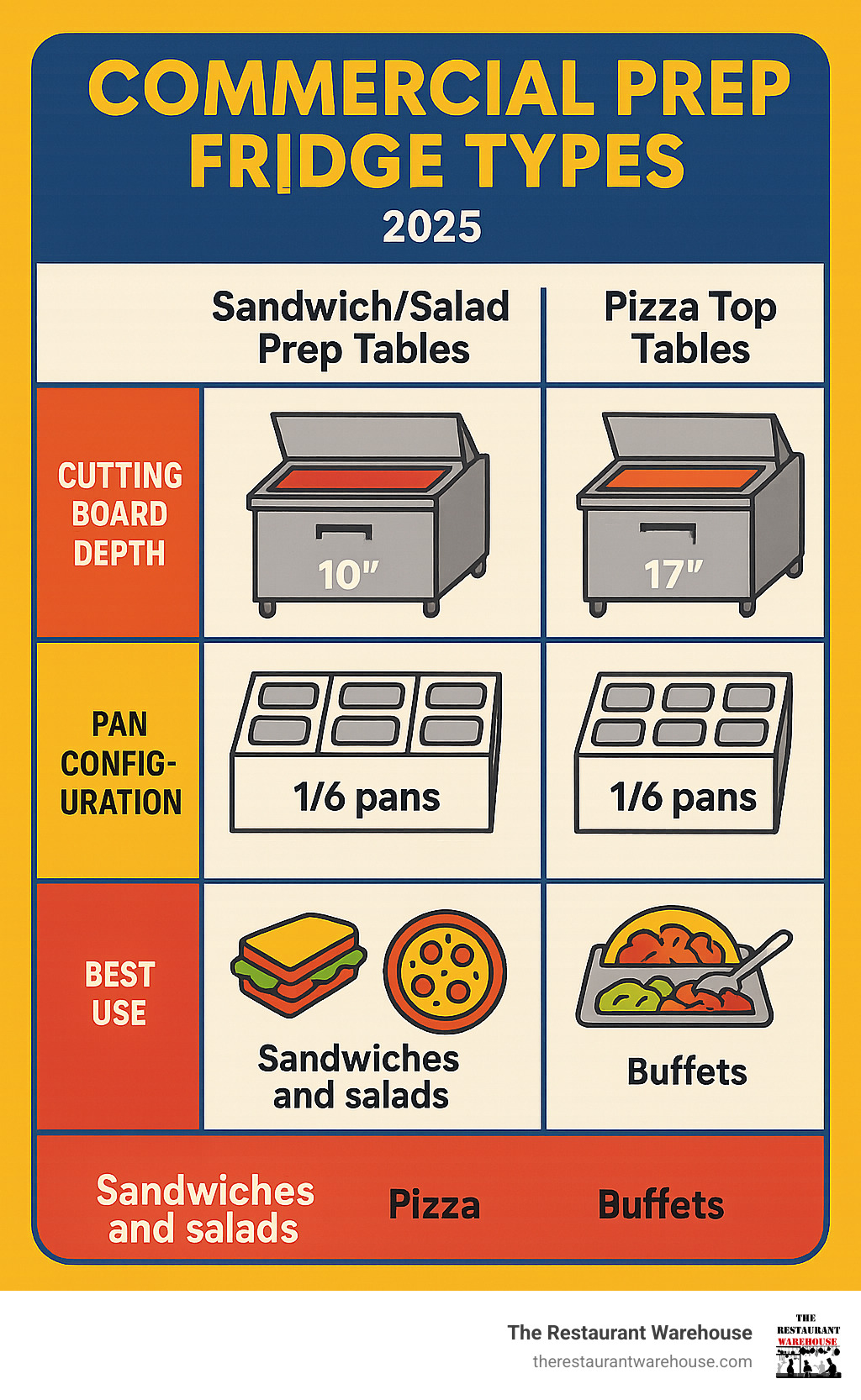

Sandwich and Salad Prep Tables

These versatile units are the workhorses of delis, cafes, fast-casual restaurants, and ghost kitchens. Their features are carefully designed for the quick assembly of customized orders.

- Recessed cold wells: These cut-outs in the top hold standard 1/6-size food pans, keeping a wide variety of ingredients chilled and easily accessible. The recessed design helps maintain temperature and prevents spillage onto the work surface.

- Standard cutting boards: Typically 10-12 inches deep and made from durable, easy-to-sanitize high-density polyethylene, they provide a clean, stable workspace for slicing and assembly.

- 1/6-size food pans: The standard configuration uses smaller pans, which is ideal for holding a diverse array of ingredients needed for customizable sandwiches and salads. This allows for greater menu flexibility.

- Door and Drawer Combinations: Many models offer a mix of doors for bulk storage and drawers for organizing smaller items. Drawers can hold pre-portioned meats or cheeses, further speeding up the assembly process.

For delis and cafes, these tables are indispensable. They streamline order fulfillment by allowing staff to build complex, multi-ingredient orders efficiently from a single, organized station.

Pizza Prep Tables

Pizza prep tables are precision instruments designed specifically for pizzerias and Italian restaurants. Their distinctive features cater to the unique, high-volume demands of pizza making.

- Raised pan rails: Ingredient pans are lifted above the work surface on an angled rail. This ergonomic design allows easy access to toppings without disturbing the pizza base and prevents cheese or sauce from falling onto the dough prematurely.

- Deeper cutting boards: With depths of 16 to 20 inches or more, these provide a generous workspace for stretching large pizza doughs, applying sauce, and arranging toppings.

- 1/3-size food pans: These tables use larger pans to accommodate high-volume toppings like shredded mozzarella, pepperoni, and mushrooms, reducing the frequency of refills during busy dinner rushes.

- Marble or granite top options: For artisan pizzerias, these premium surfaces are a worthy investment. They naturally stay cool, which prevents dough from becoming sticky and difficult to handle, providing a smooth, professional-grade handling surface.

Mega Top and Specialized Units

For operations with extensive menus or unique service models, specialized units offer improved capacity and functionality.

- Mega top units: These are a boostd version of a sandwich table, featuring an extra-wide top rail that accommodates an additional row of food pans (typically three rows instead of two). The increased pan capacity is ideal for kitchens with complex menus or extremely high volume, as the extra rows of pans significantly reduce restocking trips and keep more ingredients at hand.

- Sneeze guards for buffets: For self-serve applications like salad bars or build-your-own-bowl concepts, prep fridges can be fitted with transparent acrylic or glass sneeze guards. These are essential for protecting food from airborne contaminants while maintaining full visibility for the customer.

- Chef bases: Also known as low-boy refrigerators, these are low-profile units consisting of refrigerated drawers. They are designed to sit directly under countertop cooking equipment like griddles or charbroilers, providing immediate access to raw ingredients like burger patties, steaks, and fish fillets right on the hot line.

- Undercounter Prep Tables: For kitchens with severe space constraints, these compact units offer the benefits of a prep table in a smaller footprint. They can be tucked under existing counters to create an efficient, out-of-the-way prep station.

Choosing the Right Commercial Prep Fridge for Your Kitchen

Choosing the right commercial prep fridge is a crucial decision that requires a careful balance of your kitchen's physical space, menu demands, and budget. To find the perfect unit that will serve as a long-term asset, you must analyze several key factors before making a purchase.

- Size and capacity: Before you even browse, measure your available space carefully. Note the maximum width, depth, and height. Account for door swing clearance and ensure there's enough room for staff to move around the unit. Prep tables range from compact 29-inch models to massive 93-inch units. Your capacity needs should be based on your peak service hours and the number of unique ingredients you need accessible at all times.

- Energy efficiency: An energy-efficient model is not just good for the environment; it's a smart financial decision. Look for Energy Star certified models and those using modern refrigerants to significantly lower your monthly utility bills. An efficient unit also puts less strain on its components, often leading to a longer operational lifespan.

- Material and construction: A commercial kitchen is a demanding environment. Your prep fridge must be built to withstand constant use. Durable materials and robust construction will ensure your investment holds up over time, resisting dents, scratches, and corrosion.

- Budgeting and long-term value: Think beyond the initial sticker price. A slightly more expensive unit with superior energy efficiency, better construction, and a stronger warranty can offer far greater long-term value. Calculate the total cost of ownership, which includes the purchase price plus estimated energy and maintenance costs over several years.

Essential Features for Your Commercial Prep Fridge

Certain features distinguish a great commercial prep fridge from a mediocre one. These details have a significant impact on daily operations, food safety, and ease of use.

- Digital temperature controls: These are essential for food safety and regulatory compliance. They allow for precise temperature management, typically between 33°F and 41°F. Look for models with a clear external digital display and high/low temperature alarms.

- Stainless steel construction: 304-grade stainless steel is the gold standard for food service equipment. It contains higher levels of chromium and nickel, making it exceptionally resistant to corrosion and rust, especially in humid or coastal environments. 430-grade is a more economical, yet still durable, option suitable for less demanding applications.

- Self-closing and stay-open doors: This dual-function feature is invaluable. Self-closing doors prevent energy waste and temperature fluctuations by ensuring they are never left ajar during a rush. The stay-open feature (usually past 90 degrees) is a lifesaver when loading or unloading large quantities of stock.

- Adjustable shelving: Heavy-duty, PVC-coated wire shelves offer the flexibility to customize your internal storage space as your menu or inventory changes. This allows you to accommodate everything from small containers to large stock pots.

- Casters for mobility: Heavy-duty casters (wheels) are a must-have. They make it incredibly easy to move the heavy unit for deep cleaning underneath and behind it, which is often a health department requirement. Look for front-locking casters to ensure the unit remains stable during use.

- NSF certification: This certification from the National Sanitation Foundation ensures the unit is designed and constructed in a way that promotes food safety. It means the materials are non-porous, easy to clean, and resistant to harboring bacteria. This is often a non-negotiable requirement by local health departments.

Understanding the Technical Specifications

Getting familiar with the technical details will help you make a smarter, more informed choice.

- Compressor location: Rear-breathing units are common but require several inches of clearance behind them for ventilation. Front-breathing models are ideal for tight spaces where the unit will be flush against a wall or other equipment. Side-mounted compressors are another option that can be easier to access for service. Proper clearance is vital for performance and longevity.

- Refrigerant type (R290): Modern, eco-friendly units use R290 (propane) refrigerant. It has a very low Global Warming Potential (GWP) and is highly energy-efficient, helping to reduce your carbon footprint and operating costs.

- Insulation type (Polyurethane): High-density, foamed-in-place polyurethane insulation is crucial. This CFC-free insulation provides excellent thermal retention, ensuring temperature stability and reducing how hard the compressor has to work.

- Cooling System (Forced-Air vs. Cold-Wall): Most modern prep tables use a forced-air (or dynamic) system, which uses fans to circulate cold air evenly throughout the cabinet and pan rail. This ensures quick temperature recovery after doors are opened. Older or cheaper models might use cold-wall (static) cooling, which can be less consistent.

- Electrical requirements (Amps, Voltage, Phase): Always verify the unit's electrical specifications. Ensure its voltage (e.g., 115V), amperage, and phase (usually single-phase) requirements match your kitchen's electrical system to avoid costly installation errors, performance issues, or safety hazards.

Maximizing Your Investment: Maintenance, Troubleshooting, and Support

Proper, consistent maintenance is the key to maximizing the return on your commercial prep fridge investment. A few minutes of daily and weekly care can prevent catastrophic breakdowns during a busy service, guarantee food safety, lower your energy bills, and significantly extend the life of your equipment. Given the demanding, high-stakes environment of a commercial kitchen, proactive upkeep is not just recommended—it's essential for reliable performance and profitability.

Key Maintenance and Servicing Practices

Most routine maintenance tasks are simple and can be integrated into your staff's daily and weekly cleaning schedules. Creating a checklist can ensure these critical tasks are never overlooked.

- Daily Cleaning: At the end of each shift, wipe down all interior and exterior surfaces with a food-safe sanitizer. Remove, empty, and clean all food pans. Sanitize the cutting board thoroughly. Check that drain lines are clear of food debris.

- Weekly Gasket Inspection: Check door gaskets for cracks, tears, or hardening. A compromised seal allows cold air to escape, forcing the compressor to work overtime and wasting energy. Test the seal by closing a dollar bill in the door; if it pulls out with no resistance, the gasket likely needs replacement.

- Monthly Condenser Coil Cleaning: This is the single most important maintenance task. A clogged condenser coil is the leading cause of cooling failure. Once a month, disconnect the power, locate the coil (usually behind a front or rear grille), and use a stiff brush and a vacuum to remove all accumulated dust, grease, and debris. A clean coil allows the unit to dissipate heat efficiently.

- Quarterly Temperature Calibration: Every few months, check the accuracy of the unit's thermostat. Place a calibrated food thermometer in a glass of water in the center of the unit for several hours and compare the reading to the digital display. Adjust as needed.

- Annual Professional Servicing: Schedule a comprehensive check-up with a qualified refrigeration technician once or twice a year. They can perform more complex tasks like checking refrigerant levels, inspecting electrical components, testing fan motors, and identifying potential issues before they become major problems.

Common Issues and How to Resolve Them

Knowing how to troubleshoot common issues can save you from an expensive service call. Always start with the simplest checks (Is it plugged in? Is the circuit breaker tripped? Are the temperature settings correct?) before assuming a major failure.

- Temperature Fluctuations / Not Cooling Properly: This is the most common issue. First, clean the condenser coil. Second, check for overloaded pans or blocked internal airflow. Third, inspect the door gaskets for a proper seal. If the problem persists, it may be a refrigerant leak or a failing compressor, which requires a technician.

- Water Leakage on the Floor: This usually indicates a clogged or frozen defrost drain line. Locate the drain hose and use a pipe cleaner or compressed air to clear the blockage. Also, check the drain pan underneath the unit to ensure it isn't cracked or overflowing.

- Excessive Frost Buildup: This means warm, moist air is entering the unit. The most common cause is a faulty or dirty door gasket. Ensure doors are closing completely and the gaskets are clean and sealing tightly. A faulty defrost system (heater, timer, or sensor) can also be the cause and requires professional service.

- Compressor is Noisy or Constantly Running: A dirty condenser coil will cause the compressor to run hotter and longer. Start by cleaning it. If the unit is still constantly running, it may be low on refrigerant. If you hear loud grinding or clanking sounds, shut the unit off immediately and call an expert, as this indicates a serious mechanical problem.

- Door Sealing Problems: If doors are not closing properly, check for sagging hinges that may need adjustment or replacement. Clean the gaskets thoroughly to remove any grime that could prevent a tight seal. If a gasket is torn or permanently deformed, it must be replaced.

For any complex electrical, refrigerant, or compressor issues, always call a licensed professional. Attempting these repairs yourself can be dangerous, void your warranty, and often lead to more expensive, irreversible damage. A good unit comes with a solid warranty (often 2-3 years for parts/labor and 5-7 years for the compressor), which is your safety net. Most manufacturers require proof of regular maintenance to keep the warranty valid.

Frequently Asked Questions about Commercial Prep Fridges

We understand that investing in a critical piece of equipment like a commercial prep fridge brings up plenty of questions. Making an informed decision is vital for your kitchen's success. Here are the questions that come up most often, along with our straightforward, expert answers to help you choose, install, and operate your unit with confidence.

How long should I wait before plugging in my new prep fridge?

It is absolutely critical to let your new commercial prep fridge stand upright and unplugged for a period after delivery. During transport and handling, the refrigerant and the lubricating oil within the compressor can shift and settle in the wrong parts of the sealed system. Plugging it in too soon can cause the compressor to start without proper lubrication, leading to immediate and catastrophic damage.

- Refrigerant Stabilization: The system needs time for the refrigerant to drain back into the compressor and for the oil to settle where it belongs.

- Recommended Waiting Period: As a general rule, wait at least 4 hours if the unit was kept upright during transport. If you know or suspect the unit was tilted or transported on its side, you must wait a full 24 hours.

- Manufacturer's Instructions: Always prioritize the user manual. The manufacturer will provide the specific waiting period required for your model. Following this guideline is essential to protect your equipment and ensure your warranty remains valid.

What is the ideal temperature for a commercial prep fridge?

Maintaining the correct temperature is non-negotiable for food safety, product quality, and health code compliance.

- The Food Safety Zone: The ideal and legally required temperature range for a commercial prep fridge is 33°F to 41°F (0.5°C to 5°C). This range keeps food safely out of the temperature 'danger zone' (41°F to 135°F) where bacteria multiply rapidly, in line with FDA and local health department guidelines.

- Optimizing for Ingredients: Within this safe range, you can fine-tune the temperature. For example, keeping the unit closer to 34°F-36°F is ideal for preserving the crispness of delicate greens, while a slightly warmer 38°F-40°F might be suitable for cheeses and cured meats.

- Thermostat Best Practices: Use the precise digital controls to set your target temperature. However, it's a crucial best practice to verify the internal temperature daily using an independent, calibrated thermometer placed inside the unit.

How do I choose the right size prep fridge for my space?

Careful planning and precise measurements are essential to select the right size prep fridge for your kitchen's unique layout and workflow.

- Measure Your Physical Space: Use a tape measure to determine the exact length, depth, and height of the area where the unit will go. Don't forget to account for door swing clearance and any overhead obstructions like low-hanging shelves or fire suppression systems.

- Factor in Ventilation Clearance: All refrigeration units require space for air circulation to dissipate heat from the compressor. Check the manufacturer's specification sheet for minimum required clearances (typically 1-3 inches on the sides and/or back). Failing to provide this space will cause the unit to overheat and fail prematurely.

- Calculate Your Capacity Needs: Assess your menu and volume during peak hours. How many food pans do you need accessible on the top rail? How much backup product do you need in the refrigerated cabinet below? A unit's width (e.g., 29-inch vs. 60-inch) and its internal cubic feet measurement will determine its total capacity.

- Consider Kitchen Flow: The commercial prep fridge should improve, not hinder, your kitchen's workflow. Visualize how staff will move around the unit during a busy service. Placing it correctly can prevent bottlenecks and improve overall team efficiency.

Can I use a residential refrigerator for my business?

No, you should never use a residential refrigerator in a commercial food service setting. They are not designed for this environment for several critical reasons. They lack the power to maintain safe temperatures with frequent door openings, they are not built with the durability to withstand a commercial kitchen's demands, and most importantly, they are not NSF Certified, meaning they do not meet the health code requirements for commercial use. Using one is a health code violation that can result in fines or closure.

Conclusion: The Smart Choice for a Modern Kitchen

In the high-pressure environment of a commercial kitchen, a commercial prep fridge is not a luxury—it is a fundamental component of an efficient, safe, and profitable operation. It masterfully combines refrigerated storage with an accessible work surface to revolutionize workflow, uphold the highest standards of food safety, and directly boost your bottom line. As we've covered, these units are purpose-built for specific needs, from the versatile sandwich and salad prep tables that anchor delis and cafes, to specialized pizza units and high-capacity mega tops designed for the most demanding menus.

Making the right choice involves a thoughtful analysis of your space, capacity needs, and budget. Prioritize long-term value by focusing on energy efficiency (look for R290 refrigerant and Energy Star ratings), durable construction (304-grade stainless steel), and essential features like precise digital controls, self-closing doors, and the all-important NSF certification. Your investment doesn't end at purchase. A commitment to a simple but consistent maintenance routine is crucial to protect that investment, prevent costly downtime, and ensure your unit remains a reliable partner in your success for years to come.

Investing in a high-quality, energy-efficient unit is a powerful strategic move that delivers a significant long-term ROI. This return is realized through tangible benefits: drastically reduced food waste, faster service times leading to higher table turnover, and a smoother, less stressful workflow for your staff. The continued growth of the commercial refrigeration market underscores the indispensable role of this equipment in modern foodservice.

At The Restaurant Warehouse, we understand the immense challenges and pressures of running a foodservice business. Our core mission is to level the playing field by supplying top-tier commercial restaurant equipment and food service supplies at lower prices, achieved by eliminating the high overhead costs of traditional retail showrooms. We offer wholesale pricing directly to you, so you can equip your kitchen with high-performing gear, like a quality commercial prep fridge, without compromising your budget.

We have seen how the right prep fridge can transform a chaotic kitchen into a model of efficiency and productivity. When you're ready to streamline your operations and improve your service, the perfect commercial prep fridge is waiting to become the centerpiece of your successful and profitable kitchen. Explore our complete commercial kitchen equipment guide to find the ideal prep fridge and other essential tools to build your business.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment